A Guide to Types of Mixing Equipment

Various sectors rely on mixing equipment for their operations. These gadgets help in ensuring that substances are evenly blended together. Mixing equipment is used by industries during processes such as emulsification, homogenization or blending among others. Different types of mixers have been designed to meet different industrial needs; from those that can handle dry powders to those used for mixing viscous liquids. Knowing the different kinds of mixers available will enable firms optimize their production processes because good quality products come from well mixed ingredients.

Introduction to Mixing Equipment

Definition and Purpose

What is Mixing Equipment?

Mixing equipment refers to any machinery or tool used to combine two or more substances so that they form a uniform mixture. The aim of these machines is to achieve consistency in terms of product quality throughout the entire manufacturing process. They include devices like blenders, emulsifiers and homogenizers among others whose functions vary according to materials being dealt with during production stages within an industry. Designing mixers considering various applications they may be required for has led into having diverse types which can suit different needs found in various industries.

Importance in Industrial Applications

Many industrial processes require efficient mixing which ensures ingredients are uniformly distributed thereby improving product quality standards as well as making them more predictable too. Evenness brought about by this method enhances goods’ performance hence satisfying clients’ expectation even better. Hence food processing companies, pharmaceuticals firms, chemical plants etc heavily rely upon such machines. Properly mixed components lead into improved customer satisfaction due to enhanced item functionalities. Besides that, it also quickens work thus saving time taken during manufacturing processes.

General Categories

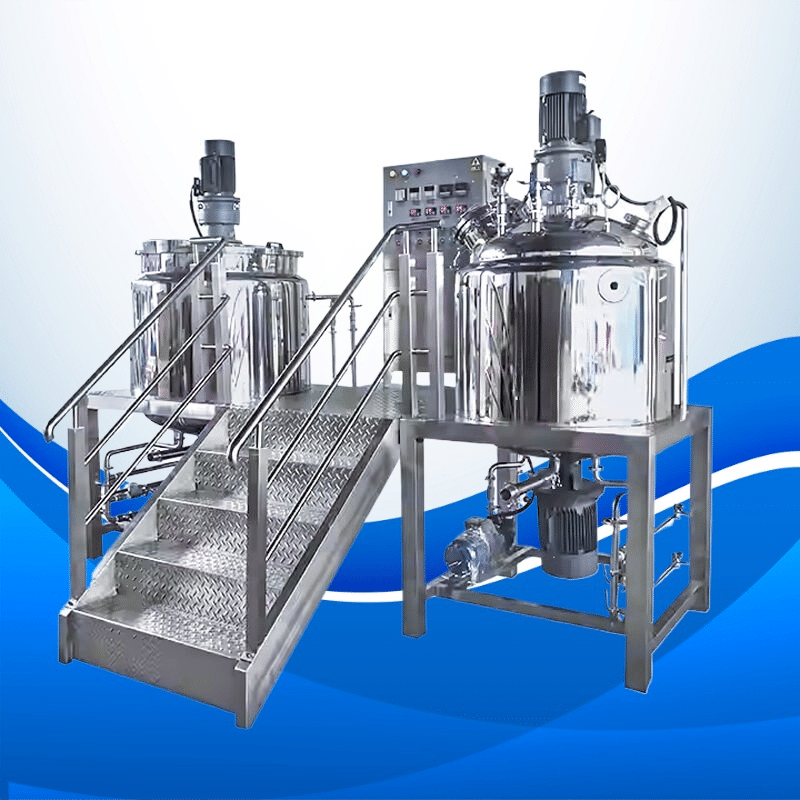

Batch Mixers

Batch Mixers

These are machines which process materials in specific quantities at a time. Operators feed the mixer with a certain amount of substance until the desired uniformity is achieved, whereafter they stop. It allows flexibility when dealing with different formulations. Batch mixers are often utilized where there is a need for accurate control over mixing time and ratios of ingredients used in making products. This makes them suitable for small-scale to medium-sized production runs.

Continuous Mixers

They work continuously without any interruptions; materials enter the mixer from one end while leaving as a homogeneous mixture at another end. Continuous mixers can be used for large quantity productions because they give uniform output and require less labor cost. Continuous mixers are necessary during manufacturing processes that involve high-volume goods. For instance, continuous mixer design enables effective utilization of raw materials within the shortest time possible, thus reducing downtime experienced in material processing industries.

Types of Mixing Equipment

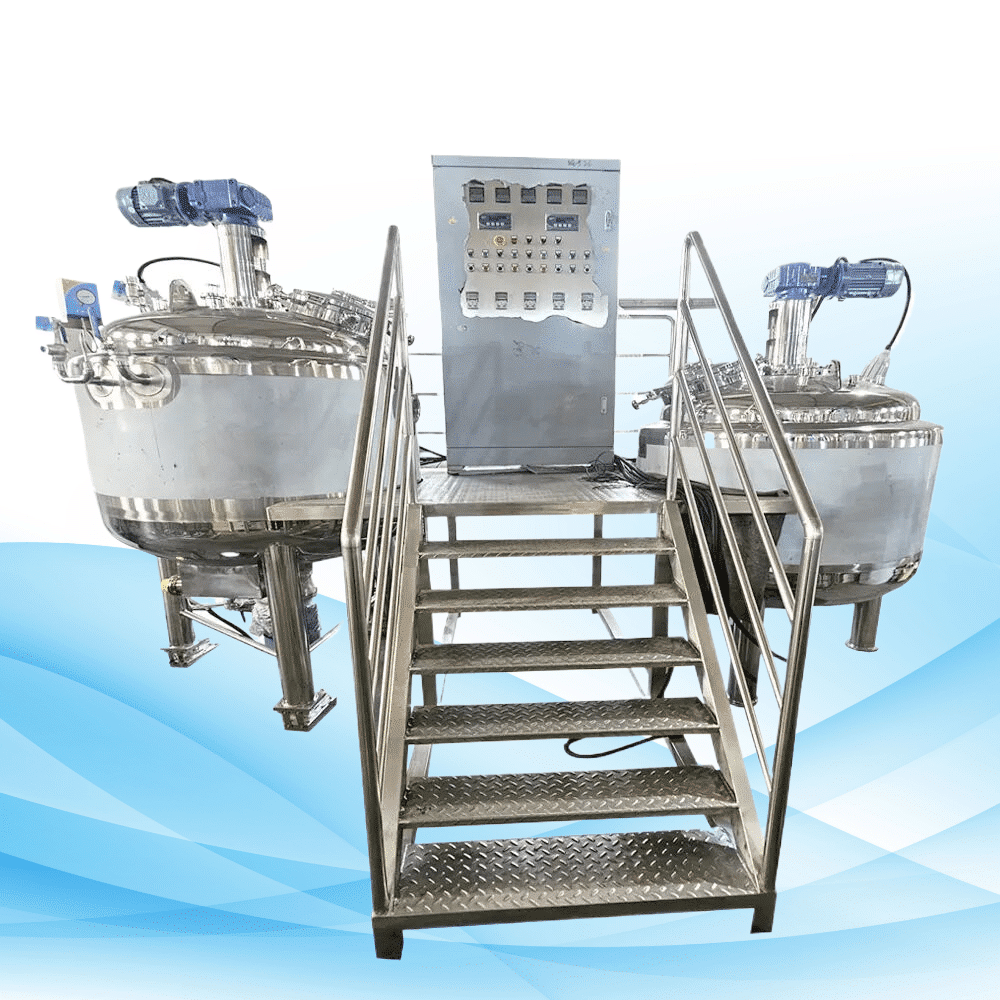

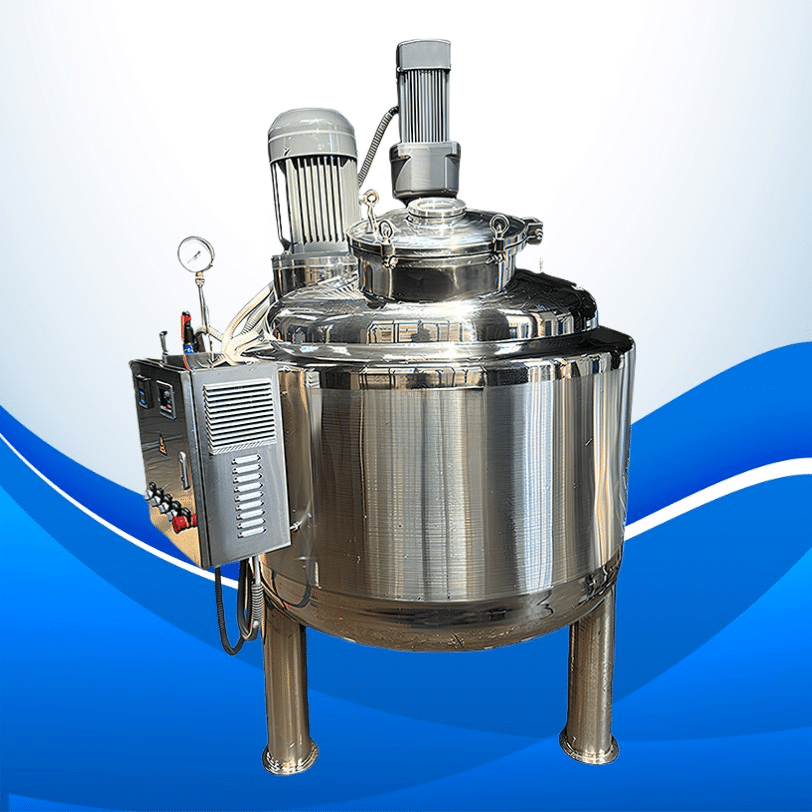

Mechanical Mixers

These use mechanical force to bring about the combination between different substances based on specified needs. Mechanical mixers have strong agitation requirements. They include Agitators and Impellers.

Agitators

Industries create motion within a liquid by using agitators during the blending process. Agitators ensure that all ingredients are uniformly distributed. Various types of agitator designs exist which can meet specific mixing requirements. They are widely applied in the pharmaceuticals industry or food processing sector among others where liquids need to be mixed together either with gases or other liquids.

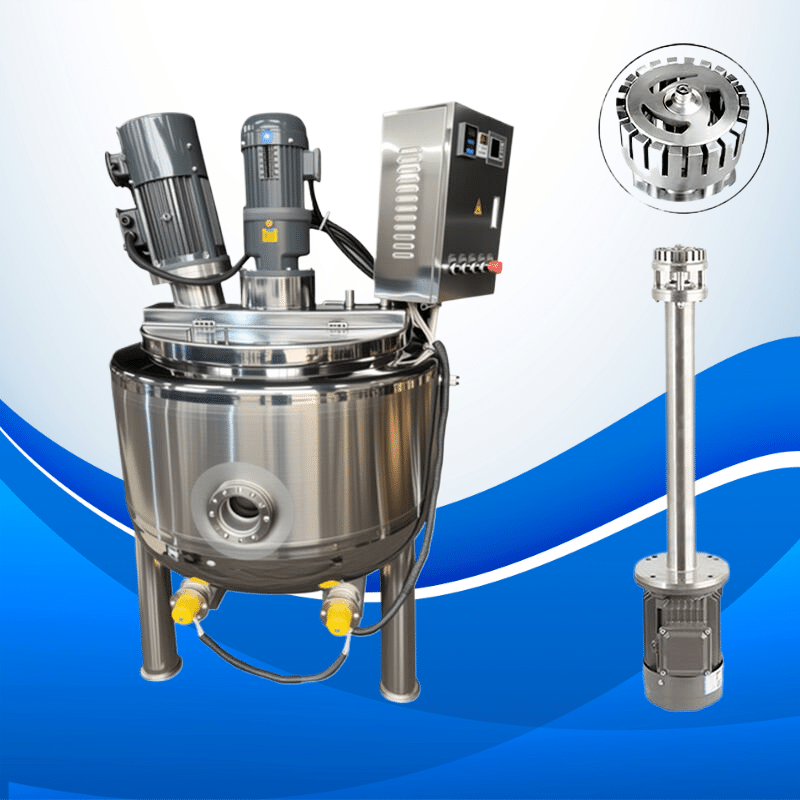

Impellers

Impellers make flow patterns inside the liquid so as to achieve the required level of mixture. Impellers work best when applied in tanks or vessels whose contents should undergo thorough stirring. Different impeller configurations depend on desired intensity levels needed during mixing activities such as heat transfer, dispersion, etc. Impeller type selection is critical for reliable consistency attainment during industrial operations.

Static Mixers

These do not contain moving parts, hence called static mixers since they perform their duties without any physical movement. Inline mixers and Motionless Mixers fall under this category.

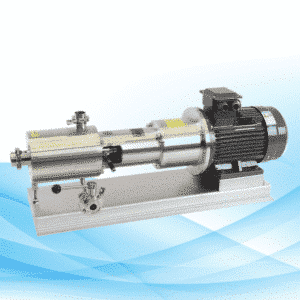

Inline Mixers

Inline Mixers

Fluids get blended while still flowing through pipes thanks to inline mixers’ action. Turbulence created by inline mixer design enhances effective merging. Where continuous operation is needed, inline mixers offer good performance with little energy consumption. Chemical blending and wastewater treatment reliability are achieved by inline mixer usage over the duration of such tasks.

Motionless Mixers

Inside a tube, motionless mixers are able to achieve mixing through static components. Motionless mixers have been designed in a way that enables efficient mixing. Among the functions carried out by these mixers include homogenization and emulsification. This makes them suitable for applications where space is limited. Also, they offer maintenance-free operation.

Specialty Mixers

Specialty mixers address specific challenges encountered during the mixing process. They consist of such types as high shear mixers or planetary mixers.

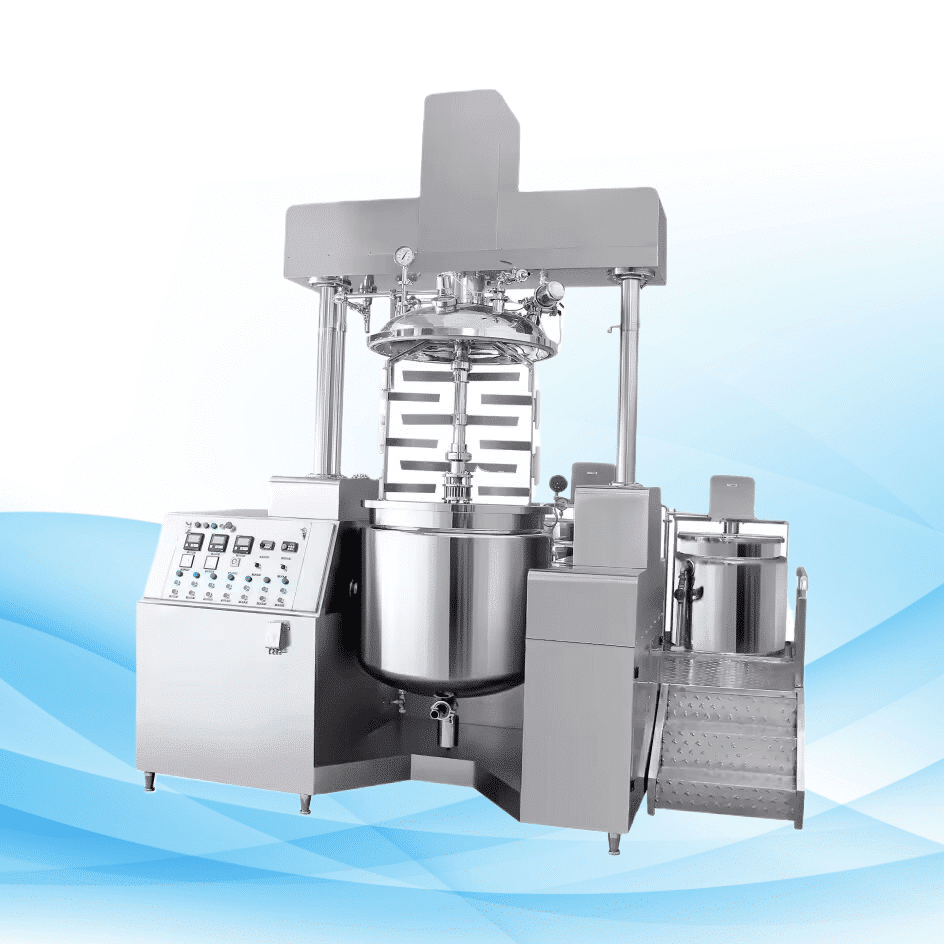

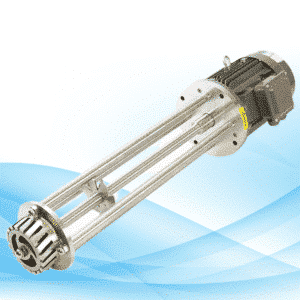

High Shear Mixers

High Shear Mixers

High shear mixers generate strong forces used in mixing. These forces can work on substances with different densities and viscosities, thus making them ideal for this purpose. The other area where they perform well is emulsifying as well as dispersing tasks during production processes. In addition, many industries use creams manufacture among other things like lotions because of their ability to do so effectively while ensuring uniform texture plus stability is achieved throughout.

Planetary Mixers

Materials mixed with planetary mixers get thoroughly blended together uniformly due to their design which provides enough surface area coverage required for thorough blending action between particles arising from material’s varying viscosities levels involved. Such kind of mixer is good at controlling mixing accuracy when working on applications that need it most i.e., dough making industry where precise amounts must be measured accurately each time before being mixed up into one batch thereby ensuring consistent results always despite fluctuations experienced during tough processes like this.

Advantages and Challenges

Mechanical Mixers

Advantages

Mechanical mixers provide significant benefits in various industrial applications since they allow more control over the process than any other type does so far. In fact, some experts argue that there isn’t another type out there capable of offering better results consistently across different industries without compromising anything else needed along the way such as versatility. Many companies rely on them just because this reason alone saves lots of money otherwise spent on buying new mixers for each specific job site which would still need more versatile ones anyway; these units can work with different materials thanks to their design flexibility. Most importantly, however (and perhaps unsurprisingly), mechanical mixers speed up production by reducing time required during processing stages, thereby increasing overall efficiency levels too. Also, they are very easy to clean.

Challenges

There are several challenges associated with the operation of mechanical mixers. Firstly, maintenance may become a problem, especially when dealing with large-scale systems, since failure parts replacement costs might exceed expected budget estimates, thereby leading to increased operational expenses. Secondly, noise and vibrations could be produced during its working process, but this can easily be addressed through proper insulation and dampening measures installation within such areas where these machines will operate from or near sensitive equipment that might get affected by them negatively if not properly managed in time. Thirdly, there is a high energy consumption rate when compared against other types available, hence it needs careful consideration during selection processes because some industries have limited power sources at times plus space limitations too.

Static Mixers

Advantages

One unique feature about all static mixers is continuous process application ability regardless of whether they use motionless elements or dynamic ones, which means no moving parts involved, thus less wear and tear occurs over long periods resulting in reduced frequency required for maintenance purposes. Another important advantage offered by this type is efficient mixing achieved without using much energy since most designs rely on flow velocity increase while maintaining constant pressure drop across the device length as shown below: ΔP = ηQ/J where ΔP stands for pressure drop, η is dynamic viscosity of fluid being mixed together with Q representing volumetric flow rate through mixer while J denotes surface area presented per unit volume occupied inside given cross-sectional plane perpendicular to direction being taken along its axis; therefore it follows that larger sizes produce better results due to increased contact opportunities offered between different components present at various points within the system under consideration.

Challenges

However, there are some scenarios where static mixers may face challenges.

Mixer machines are very essential in different sectors. They offer various solutions through mechanical mixers as well as static mixers and specialized mixers. All these types of mixer equipment serve distinct industrial needs. The vigorousness of the mixing action is what sets apart mechanical mixers from others while continuous processes are best suited for static mixers. Unique mixing challenges, on the other hand, can only be handled by specialty mixers. One has to know where they want to use it before choosing a mixer machine since its selection depends on this factor alone, considering that there are many such machines available today. Material type and production scale among other things like that have to be considered by industries when selecting these machines because without them then there will never be any efficiency in processes or even good quality products at all.