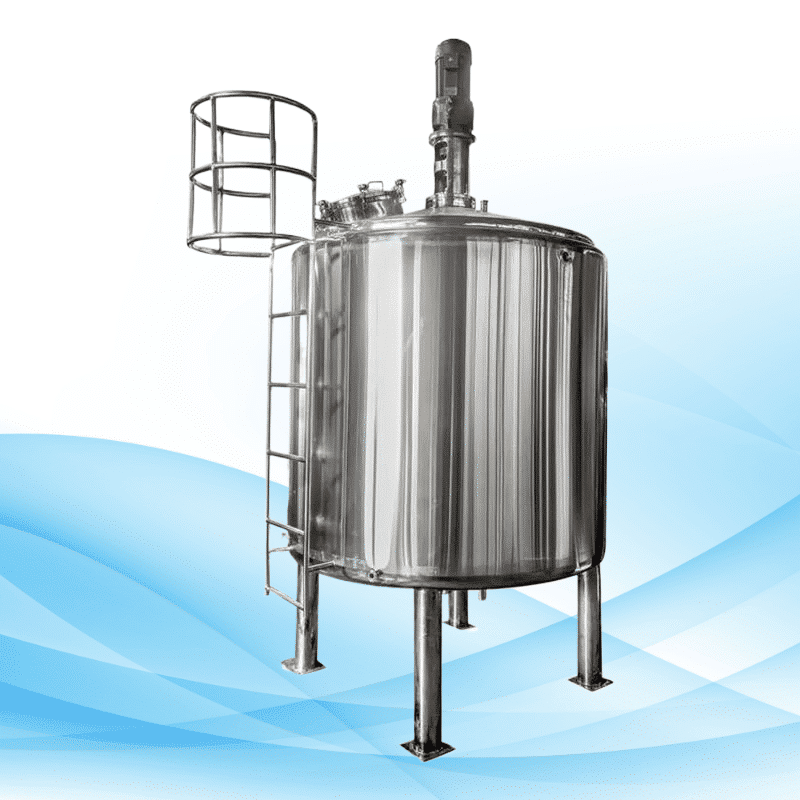

It is indisputable that the appropriate tools have an indispensable impact when it comes to large-scale mixing. For instance, the 1000 gallon mixing tank is a perfect option for industries that require both accuracy and the mixing of large quantities of chemicals. Whether used in chemical, pharmaceutical, cosmetic, or food industries, these tanks can provide an ideal output and are flexible in their design.

What is a 1000 Gallon Mixing Tank?

The 1,000 gallon mixing tank is a type of industrial tank that has a large volume and is used for the purposes of mixing, blending, or agitating substances. Considering the fact that this tank is a thousand gallons in size explains its suitability for large production areas where batch consistency and speed of working are imperative. These tanks are integrated into the facility with high mixing capability and may be made in various designs to enhance the elements of the process.

Material Options: 304 or 316L Stainless Steel

304 Stainless Steel

304 stainless steel should be used for most common mixing processes where the medium is not highly corrosive. It is highly effective for food and beverage manufacturing because it is cost-efficient and astonishingly effective against corrosion.

316L Stainless Steel

316L stainless steel is the material of choice for applications that involve extreme corrosive materials. This material also exhibits increased corrosion resistance, which will be beneficial in the pharmaceutical and chemical industries that deal with aggressive substances. It also has low carbon content, making it ideal for ultra-clean environments.

Choose from a Variety of Agitators

Your mixing tank’s productivity also relies on the correct application of the agitator, which may be acquired separately. Our 1000 gallon mixing tanks allow for multiple attachable agitators to meet various mixing needs:

Propeller Agitators

Effective for low viscosity fluids, making sure that liquid blending and circulation in the tank are enhanced.

Turbine Agitators

Most suitable for materials with medium to high viscosity requiring strong mixing and enhanced dispersion of the materials.

Helical Ribbon Agitators

Ideal for mixing extremely high viscosity materials such as pastes and creams, ensuring well-mixed products during each batch.

Mixing Tanks of the 1000 Gallon Capacity with a Three-Layer Jacket

In our 1000 gallon mixing tanks, we have used a tri-layer structure to achieve effective thermal management and product safety:

Inner Layer

The product is in direct contact with this layer, made of either ethylene, hydrocarbon, or stainless steel grade 304 or 316L, depending on the application requirements.

Middle Layer

This serves the purpose of a jacket, allowing water, steam, or oil to pass around the product, thus controlling its temperature.

Outer Layer

This adds insulation and protection, helping keep the energy used for heating or cooling the tank.

Heating Options: Electric Heating and Steam Heating

To improve the performance of your 1000 gallon mixing tank, there are two options for heating the tank:

Electric Heating

With this option, the temperature of the product can be held in a clean manner. Electric heating ranges from 1.5KW to 55KW, which is ideal for processes that need specific temperatures maintained and adjustable.

Steam Heating

Steam heating is an affordable option for industries that already incorporate steam into their processes. The jacketed design allows for the application of steam for quick heating, which is desired in large-scale operations where high thermal efficiency is required.

Voltage Options from 220V to 600V

As for the motor’s voltage, our 1000 gallon mixing tanks can withstand a range of 220V to 600V. This scope is suitable for straightforward incorporation into the power systems already existing within your establishment.

Diverse Application across Multiple Industries

The 1000 gallon mixing tank is suitable for a variety of industries, including:

Pharmaceuticals

Guarantees even distribution of chemical agents, suspensions, and liquid preparations.

Cosmetics

Allows homogeneous mixing of creams, lotions, etc.

Food and Beverage

Efficient for the mixture of large volumes of sauces, syrups, and other food products.

Chemical Processing

Specializes in handling aggressive chemicals with 316L stainless steel for strength and safety.

Paint and Coatings

Able to add heavy materials such as pigments and resin for a more even mixture and smooth finish.

Frequently Asked Questions (FAQ) About 1000 Gallon Mixing Tanks

What agitation method should I use for my specific task?

The type of agitator to use is determined by the viscosity and type of material you want to mix. For low viscosity liquids such as water, a propeller agitator is the best choice. For thicker liquids, a turbine or helical ribbon agitator provides better mixing efficiency.

Is the heating method for the mixing tank configurable?

Yes, our 1000 gallon mixing tanks can be fitted with either electric heating or steam heating systems depending on process requirements.

Which is better, 304 or 316L stainless steel?

304 stainless steel is low cost and optimal for a broad range of applications. In contrast, 316L stainless steel provides better resistance against corrosion and is ideal for industries dealing with aggressive or corrosive environments such as chemicals and pharmaceuticals.

What are the available power and voltage options?

Power ratings start from 1.5KW to 55KW, with a voltage range of 220V to 600V, ensuring compatibility with your facility’s energy specifications.

Which industries can use a 1000 gallon mixing tank?

These tanks are used in pharmaceutical, cosmetic, food, beverage, chemical, and paint industries. Their wide range of designs and dimensions, along with the option for customization, makes them suitable for mass production systems.

How does the jacketed layer assist in temperature control?

The jacketed layer allows for the introduction of steam or water, which helps control the temperature during mixing. This is essential in industries like textiles where consistency in temperature is crucial for product quality.

Contact Us Today for Your 1000 Gallon Mixing Tank Needs

Choosing the right 1000 gallon mixing tank can significantly enhance the convenience and quality of your production cycle. Our tanks can be customized with different materials, agitators, heating methods, and power configurations to suit your industry. Contact us today to find out how our tanks can be tailored to meet your requirements and improve your operational effectiveness.