1000 gallon Chemical mixing tank

- Capacity: 50 liters to 30,000 liters

- Mixer power: 1.5 kW to 55 kW

- Material: 304 or 316L

- Voltage: 110V to 600V

- Heating method: Electric or steam heating

- Layer:single/double jacket/three jacket

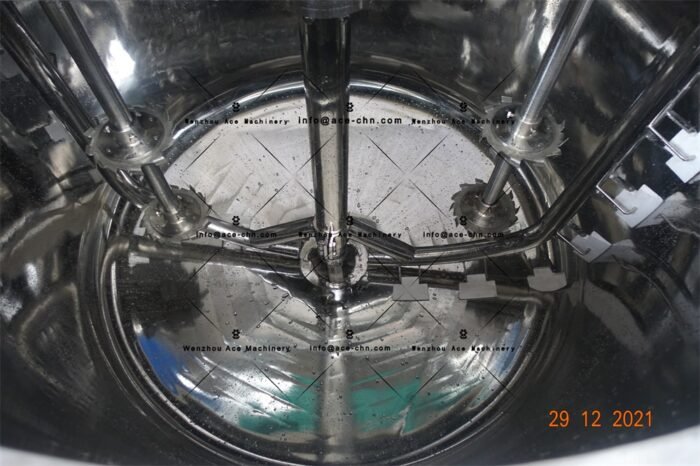

- Mixer types: Impeller-type, Anchor-type, Turbine-type, High-shear-type, Magnetic mixer, Anchor-type mixer with scrapers,dispersing

- Optional: platform, wheels, ladder,variable frequency drive,explosion-proof device

- Certificates: ASME, CE, GMP, UL, ATEX, ISO 9001

- Our equipment supports customisation, global delivery, and a 1-year warranty.

- If you have drawings, we can process them for you.

Note: Please contact our sales team before placing an order. Website prices are for reference only; specific pricing requires understanding your requirements to provide a quote.

Email:info@ace-chn.com

Tel: +86 186 2683 5909

WeChat: ace-chn

WhatsApp: +86 186 2683 5909

$21,000.00

Guaranteed Safe Checkout

Recommend RPM: 0-960RPM

Viscosity: Low/medium viscosity

Application: Mainly Liquid mixing

Recommend RPM: 0-200RPM

Viscosity: Low/medium viscosity

Application: Mainly Liquid mixing

Recommend RPM: 30RPM

Viscosity: Medium/High viscosity

Application: Melting, High viscosity product mixing, For single wall tank

Recommend RPM: 30RPM

Viscosity: Medium/High viscosity

Application: Melting, High viscosity product mixing, For jacket tank

Recommend RPM: 1480/2850 RPM

Viscosity: Low/medium viscosity

Application: Liquid powder mixing and dispersion

Recommend RPM: 1480/2850 RPM

Viscosity: Low/medium/High viscosity

Application: Liquid powder mixing and homogenizing

Recommend RPM: 0-355RPM

Viscosity: Low/medium viscosity

Application: Install at bottom, No mechanical seal working condition

Recommend RPM: As above

Viscosity: Low/medium viscosity

Application: Liquid powder mixing and dispersion For tank volume >300L

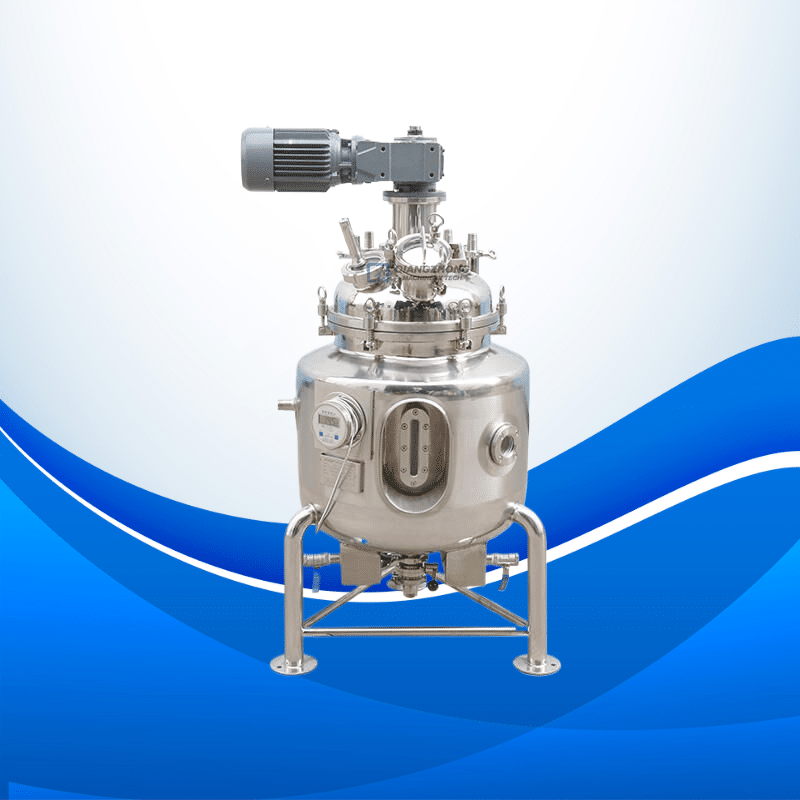

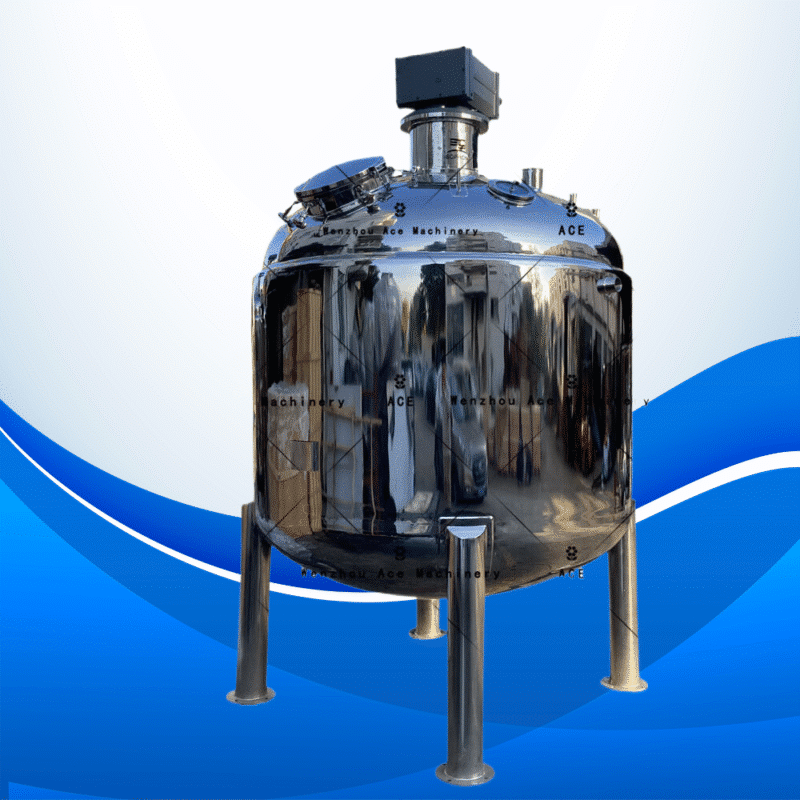

If you want a reliable way to handle chemical mixtures, there is no better option than our Chemical Mixing Tank. It may be used in various industries such as pharmaceuticals, cosmetics, food and beverages, as well as chemicals because these tanks ensure thorough mixing, heating, and processing of different materials. You can choose between a small 50-liter tank or even a large 30,000-liter one – we offer custom-made solutions for any requirement.

High-quality Materials and Sturdy Build

Our Chemical Mixing Tanks are made of top-grade stainless steel (316L and 304). The first type mentioned above provides excellent resistance against corrosion or chemical damage, making it most suitable for applications where this feature may be needed; on the other hand, the 304 variant offers good durability combined with cost-effectiveness, which makes it perfect for many uses. Thanks to robust construction, these vessels will serve you long enough, thus becoming worth every penny spent on them.

Adaptable Heating Methods

For different processing needs, there are two types of heating available with Chemical Mixing Tanks:

Electric Heating

When precise temperature control is required, electric heaters ensure uniform heat distribution throughout the entire vessel, making them applicable even in cases involving very delicate chemical reactions.

Steam Heating

This method works faster due to higher efficiency but also allows quick cooling down after use, which saves time, especially during production cycles requiring frequent changes from hot to cold media.

Wide Range of Configurations

Each Chemical Mixing Tank can be equipped with various options depending on specific requirements:

Mixing Mechanism

Propeller, turbine, paddle, agitator, anchor, etc., should be selected according to material viscosity.

Control Systems

Advanced control panels enable easy operation, monitoring, automation, etc., so you can choose one that suits your needs best.

Insulation

If necessary for a particular process, precision temperature maintenance can be achieved by using extra insulation material like polyurethane foam, etc.

CIP/SIP Compatibility

Clean-In-Place (CIP) / Sterilize-In-Place (SIP) systems integration ensures hygienic cleaning efficiency.

Pressure/Vacuum Options

Different chemical processes require different pressure conditions, which is why some tanks may have vacuumed or pressure features built-in.

Worldwide Delivery + Great Customer Service

Regardless of where your company is based, we will deliver the Chemical Mixing Tank to you promptly and intact. Our professional support team works round-the-clock, so any question arising before, during, or after purchase will be answered without delay. We strive to make our service seamless while meeting all individual customer needs accurately.

Buy Your Chemical Mixing Tank Now!

When it comes to the chemical industry, one should never compromise on quality. The efficiency, durability, and safety offered by these mixing devices are second to none in the market, thus making them best suited for any mixing task at hand. Whether it’s a small batch mixer or a large-scale industrial model required – just let us know what exactly is needed, and we will do the rest!

Therefore, don’t waste time anymore; place your order today! You can contact us right away to discuss further details, get an estimation, etc., but please bear in mind that such high-end machines might take some time to produce and ship out depending on the current workload and capacity available at the given moment.