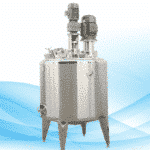

Jacketed Mixing Tank It is useful in the food, pharmaceuticals, cosmetics, chemicals, or any other industry since it accommodates a wide range of liquids, pastes, or powders. Whether you are manufacturing sauces, creams, or chemical compounds, a jacketed mixing tank guarantees high quality output every single time.

What is a Jacketed Mixing Tank?

A jacketed mixing tank is a type of tank that contains two walls. The space between both walls controls the temperature of the tank. The fluid that stays in between the walls, while cooling or heating the tank’s contents, is responsible for heating or cooling the inner tank. In this way, the contents are efficiently mixed and heated (or cooled) in the tank.

Jacketed design eliminates the concerns for contamination of temperature-sensitive materials and offers numerous key benefits to multi-wall mixing tanks. As a result, with the jacketed mixing tanks, producers eliminate the potential problems of overheating materials and while improving the overall quality of the final contents.

Key Features of a Jacketed Mixing Tank

1. Twin-Pane Structure

One of the reasons many users prefer a jacketed mixing tank is the twin pane structure that it offers. The inner tank, where materials are loaded, is placed inside an outer jacket that circulates heated or cooled fluids.

2. High Precision Control

A jacketed mixing tank also has a high level of precision control than the other types of mixing tanks. This is because they can cool and heat at the same time. This cooling and heating is crucial in processes like emulsification, homogenization, and fermentation, which are temperature dependent.

3. Application Specific Mixing

Jacketed mixing tanks are useful in various applications such as:

- Food and Beverage: Best for precision heating while mixing sauces, creams, syrups, or beverages.

- Pharmaceuticals: Used in sensitive medicine and vaccine making, and many other sensitive compounds.

- Chemicals: It is vital for the mixing of chemistries that are utilized under specific temperatures to initiate reactions.

- Cosmetics: Great for combining ointments, creams, or lotions, because they precisely control the application of heat.

4. Superior Grade Materials

These tanks are made from corrosion-resistant materials like stainless steel 316L or 304 which can withstand rigorous cleaning, assuring hygiene and reliability. They are crafted with long-lasting materials, which makes them able to resist corrosion effectively.

5. Effective Mixing Process

The jacketed mixing tanks operate with high efficiency mixer or agitator which are used for shake blending. Special machines with those functions are designed to provide proper blending for various viscosity materials in addition to heating and cooling the material to the appropriate temperature.

Advantages of a Jacketed Mixing Tank

1. Improvement of Product Quality in Every Stage of Production Exceeds the Expectation

Utilization of jacketed mixing tanks enables the improvement of the quality of the final product like creamy fine textured sauce and flawlessly seasoned boneless chicken cubes. These devices can also ensure that the ideal sauce temperature and high texture is always preserved on the chicken without burning it.

2. Enhanced Safety

Additionally, jacketed design helps reduce the risk of contamination, which enhances the protection of the product. This feature also reduces overheating that is harmful to the product or potentially causes very dangerous reactions, especially in most chemical and pharmaceutical products.

3. Saving Money

When utilizing a refrigerant that can be reused, jacketed tanks become energy efficient. This lowers operating expenses, and as a result, rationalizes the return of investment.

4. Elevated Output

Because of the blended product being in a continuous state, increased temperatures and efficient blending improving productivity translates to decreased processing time. Jacketed mixing tanks’ ability to meet deadlines can be improved thanks to this new technique.

5. Tailor Made Designs

Every business is different and as such, we tailor-make the jacketed mixing tanks to suit the client’s specifications and purposes. From the jacket configuration, the heating and cooling ability, to the agitators, these tanks can be custom made to suit your production processes.

What Makes Our Jacketed Mixing Tanks The Best?

Our company is known for our impeccable quality and dependability. No other business can create the standards we set. Each unit is built, constructed, and designed with state of the art components, machinery, and materials. Here are a few reasons to choose our tanks:

- Rugged Construction: Made out of supreme stainless steel, it can endure heavy-duty operations.

- Precise Temperature Control: Instead of soft heaters and unregulated coolers, one can completely control the heating and cooling, thus guaranteeing product consistency.

- Adaptable Applications: Perfect for the food, chemicals and pharmaceuticals manufacturing sectors.

Our prices are competitive: You understand everything correctly, these are the most inexpensive prices, and the quality of our products is never compromised.

Custom Features

At [Your Company Name], we know that every business is different. Therefore, our jacketed mixing tanks are highly customizable because of that. You may choose the size, type of agitator (top, bottom), and type of jacket system (single and double jackets). In addition, we also stock different types of steam, hot water and glycol jackets for heating and cooling.

If your industry has special requests, your wish is our command, and we will do our best to fulfill your most particular needs. We can design and produce the jacketed mixing tank that incorporates a specialized material or shape of the stirrer.

Call to Action: Place An Order For Your Jacketed Mixing Tank Today!

Are you ready to achieve all of your production goals? We are confident that our jacketed mixing tanks offer the best quality, efficiency, and multi-functionality available today. Safety, product quality, and production time are no longer an issue with our tanks.

Do not hesitate to contact us for any assistance you need regarding the ordering process. We will be happy to assist you with your mixing level needs and provide appropriate solutions.

Frequently Asked Questions (FAQs)

1. Which materials can be processed in a jacketed mixing tank?

Jacketed mixing tanks can accommodate a variety of materials including liquid, cream, emulsion, paste, and powdered forms. They are common in the food, pharmaceuticals, chemicals, and cosmetics industries.

2. How is temperature controlled in the jacketed mixing tanks?

The temperature is managed by passing steam, hot water, or glycol through the jacket, which serves as a heating or cooling fluid.

3. Can I request an agitator of my choice?

Yes, you can request an agitator of your own, as we can help you with it. We have custom-made agitators for various mixing needs. Depending on your needs, you can use top or bottom mounted agitators.

4. How large can the measurements get?

From small laboratory-scale tanks to large industrial-scale tanks, we have a wide range of measurements to choose from. All custom orders can be scaled to your desired level of production, which you can specify during the order process.

5. Are there high maintenance costs associated with the tanks?

Yes, the jacketed mixing tanks can be cleaned very easily, thus they were made for hygienic purposes. Cleaning will be a lot simpler due to the stainless steel coating, and the design optimizes washing and drainage.

In terms of budget, you will not make a mistake with our jacketed mixing tanks because they are always offered at an affordable price. Enhance your manufacturing procedures, attain consistency in all products, and protect every single batch. Order now and watch the transformation!