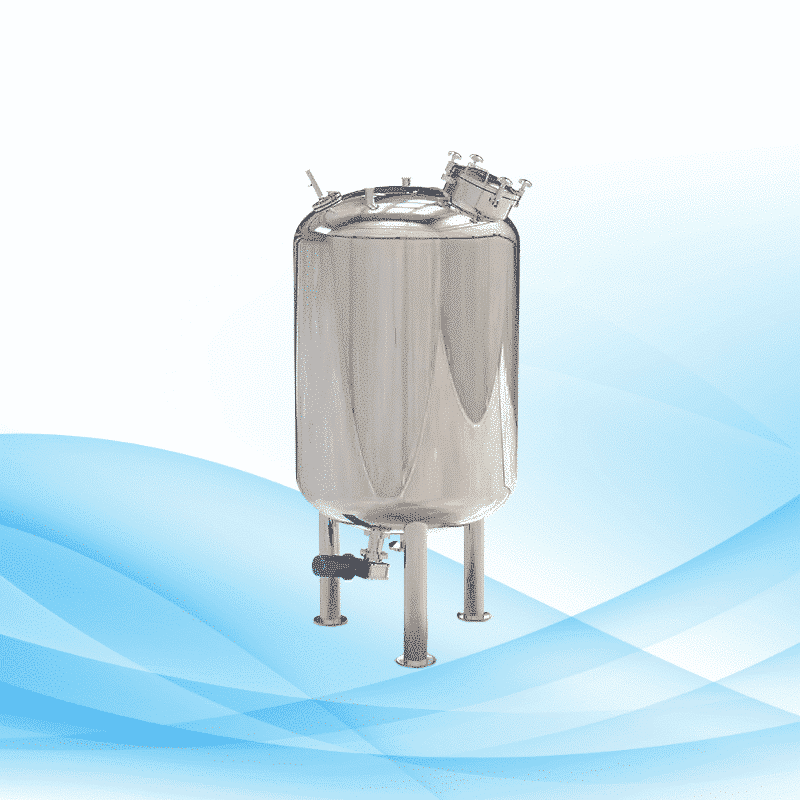

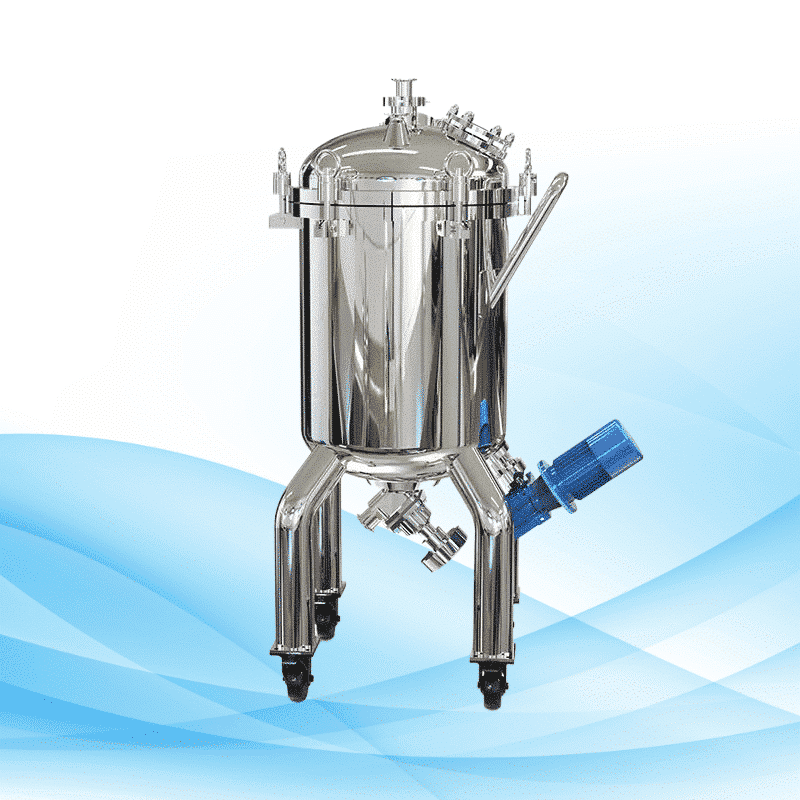

Our top-of-the-line magnetic mixing tank is made from high-quality stainless steel. It is designed to be very sturdy and resistant to rusting, since it can be fabricated using either 304 or 316L materials. This equipment was created with versatility in mind so that it can meet the needs of different industries. You can choose between electric and steam heating methods when buying this product, depending on your application.

Main Features:

- Materials of the Highest Quality: The magnetic mixer tanks are made out of stainless steel which has good corrosion resistance properties such as 304 or 316L grades, therefore they’re suitable for use in food-grade applications as well as industrial environments.

- Heating Alternatives That Save Time: To make sure that while mixing, heat control is accurate, thus enhancing efficiency and reliability during this stage; select either electric or steam heating for your system.

- Capacity Flexibility: We offer various sizes ranging from 50 liters up to 30000 liters capacity; hence you can get a tank size that suits your production requirements whether it’s small batch or large-scale production we have got all bases covered.

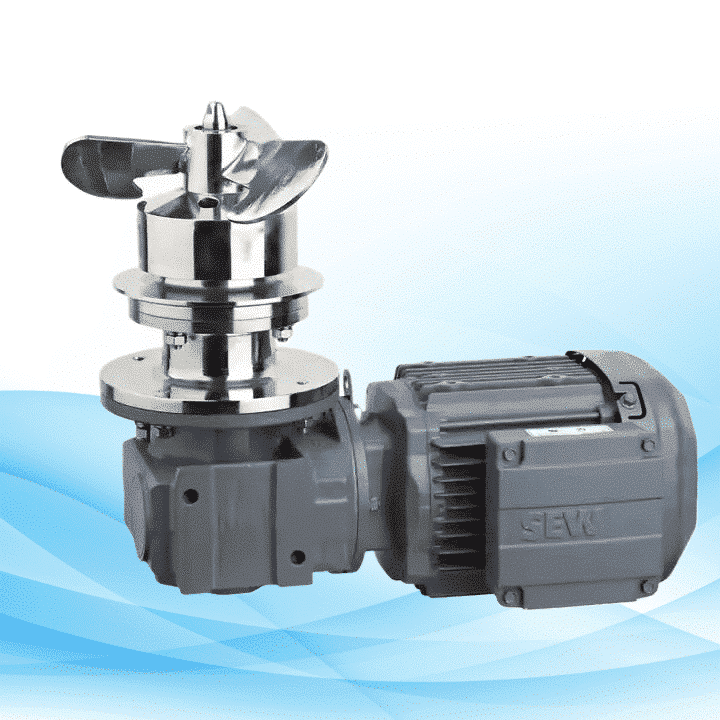

- Advanced Technology for Magnetic Stirring: There’s a magnetically driven agitator inbuilt into each container which ensures even distribution of components such as powders, fluids etc. so as not to contaminate them further leading to better quality end products being achieved always.

- Applications Versatility: Our mixers find usage across different sectors namely pharmaceuticals, chemicals, cosmetics among others where liquids need blending together with pastes or any other viscous materials that require thorough amalgamation.

Where It Can Be Used:

Pharmaceutical Industry – It creates an ideal environment for blending APIs (Active Pharmaceutical Ingredients) alongside recipients plus other sensitive substances which demand sterility during processing;

Food & Beverage – Sauces beverages jams etcetera should always have consistent taste throughout their packs, hence such products must be mixed uniformly within this type of tanks;

Cosmetics – Lotions, creams or even powders may fail to work as expected if they are not blended properly thus compromising their integrity as well as effectiveness, therefore containers with magnetic mixing system should be used here;

Chemical Processing – Some chemicals cannot be stored together without reacting hence there is need for safe mixing reactions which can only be achieved through utilization of tanks fitted with agitators driven magnetically;

Customization:

All our mixers come with various options that allow them meet individual client specifications including but not limited to; different heating methods, agitator designs among others. We have a variety of tank sizes ranging from 50 liters through to 30000 liters capacity.

Purchase one today and discover the unmatched efficiency, reliability and quality that comes with using our magnetic stirring systems. Call us now for more information or place your order online!