An emulsion mixer machine is a powerful industrial-grade device that blends emulsions, suspensions, and more sophisticated liquid compositions with precision. It is perfect for various industries like cosmetics, pharmaceuticals, food and beverages, and chemicals, as it can cope with demanding mixing tasks that require uniform quality with emulsion high shear mixing.

If your business deals with creams, paints, lotions, or sauces, the emulsion mixer machine will serve you well as it can resolve most of the blending problems that exist in modern production processes.

Emulsion mixer video

Advantages of Emulsion Mixer Machines:

- Effective Mixing: Emulsion Mixer machine utilizes advanced mixing technology to ensure heterogeneous mixtures by applying high shear strength that makes stable and well-collapsed emulsion. These are especially useful for applications that require strict particle size and uniformity.

- Higher Productivity: Due to variable motor speeds and a combination of mixing blades, emulsion mixers reduce the mixing time and improve production efficiency and output.

- Range of Use: Emulsion mixers work with an extensive array of products, from cosmetic creams to industrial paints. They have the ability to mix components with differing viscosities and densities, making them suitable for a wide range of industries.

- Cost Efficient: The emulsion mixer engine utilizes a standardized quality control while reducing mixing times, giving its users a competitive advantage by eliminating wasted costs and saving on rework due to batch failures.

- Easy Operation: The automated control system enables operators to monitor and control the settings such as speed, time, and temperature, resulting in easy adjustments tailored to each production. This maximizes business operations and gives full control of the mixing process.

Mixer parameters

| Product Model | Motor Power (KW) | Rotational Speed (RPM) | Processing Capacity (M³/H) | Standard Length (MM) |

|---|---|---|---|---|

| ACE-80 | 1.1 | 2800 | 10-40 | 450 |

| ACE-90 | 1.5 | 2800 | 20-70 | 550 |

| ACE-100 | 2.2 | 2800 | 50-100 | 650 |

| ACE-12A | 3 | 2800 | 100-200 | 700 |

| ACE-120 | 4 | 2800 | 100-300 | 750 |

| ACE-14A | 5.5 | 2800 | 200-600 | 900 |

| ACE-140 | 7.5 | 1400 | 200-800 | 900 |

| ACE-160 | 11 | 1400 | 300-1000 | 1000 |

| ACE-180 | 18.5 | 1400 | 500-1500 | 1100 |

| ACE-200 | 22 | 1400 | 800-2000 | 1100 |

| ACE-20A | 30 | 1400 | 900-2500 | 1100 |

Specifications:

- Voltage Choices: 110V to 600V

- Power Choices: 1.5KW to 55KW

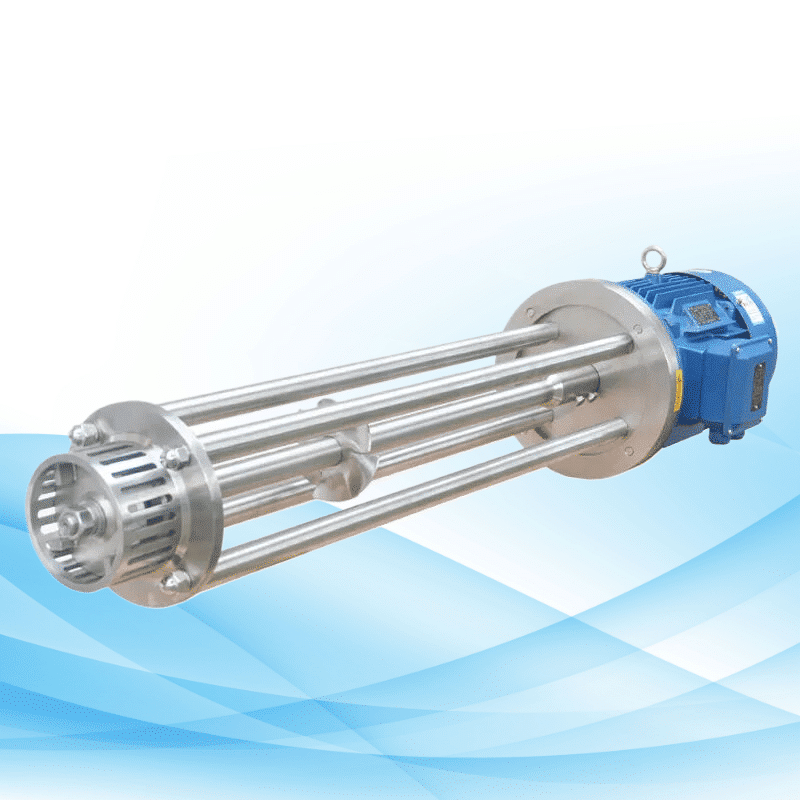

- 316L Stainless Steel: This material is preferred in the food, pharmaceutical and chemical industries due to its unmatched corrosion resistance and durability.

- 304 Stainless Steel: While still providing necessary corrosion resistance, this material is ideal for larger industrial applications without the cost of 316L steel.

- Mixing Volume: Scale up or down as per your production needs.

- Motor Revolution: The engine can have its rotation changed to vary the mixing method.

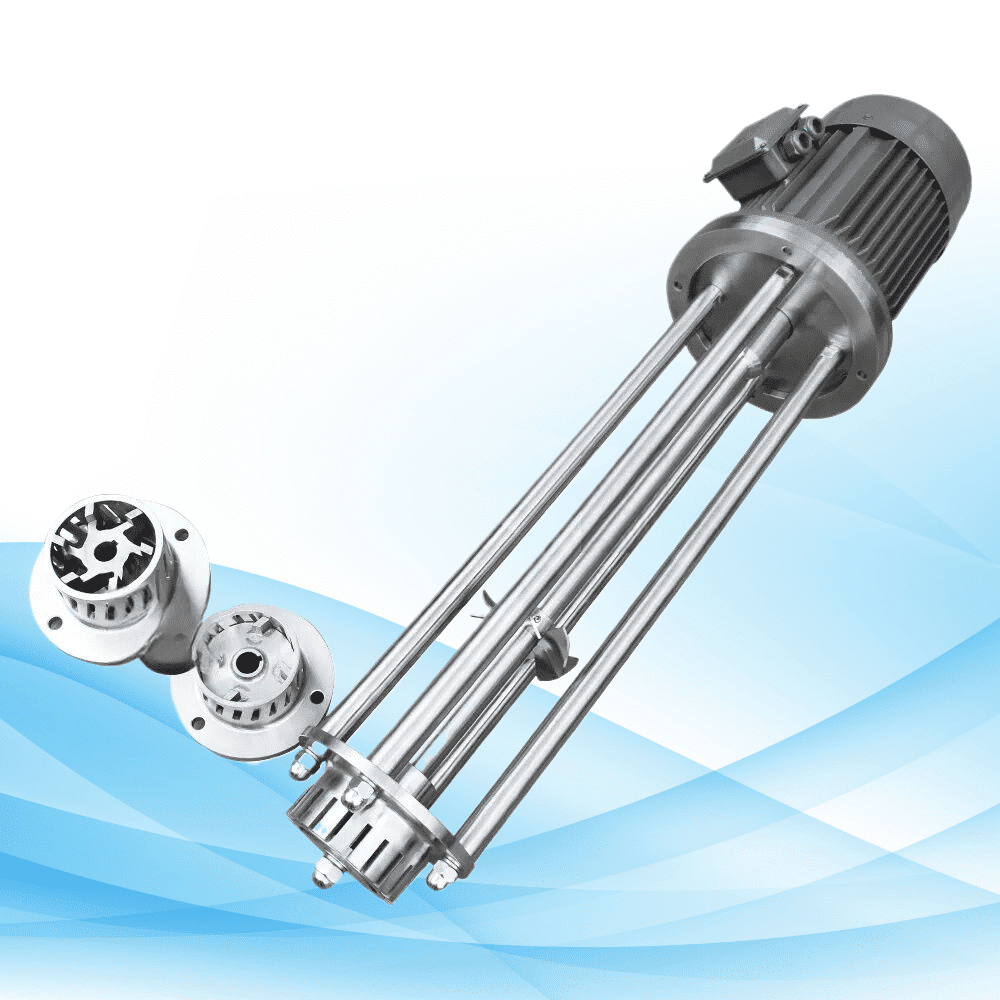

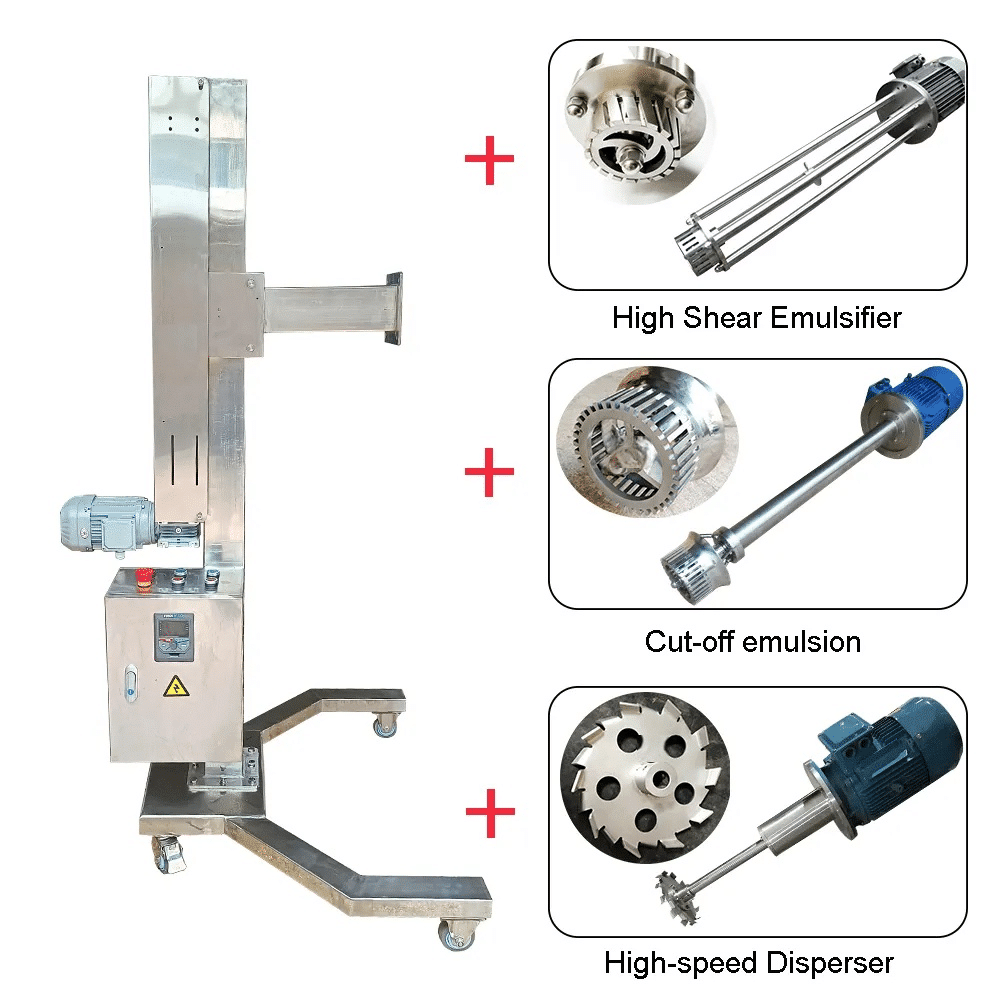

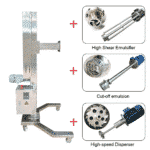

- Design: The engine may be outfitted with various rotors and stators and blades for high shear mixing devices to suit different products.

Uses of Emulsion Mixer Machine:

- Cosmetic and Personal Products: Suitable for emulsified products from lotions, creams, shampoos, and serums requiring the SAME blend and level of consistency each time.

- Pharmaceuticals: Enhance the inclusion of emulsions and suspensions in drug forms by exercising closer control of the mixing process.

- Food and Beverages: Great for sauce, dressings and dairy emulsification by ensuring that the oil and water phases are properly dispersed without altering the desired structure and quality.

- Paints and Coatings: Assists in the dispersing of pigments and solvents in paints, coatings, and inks to achieve uniform coloration and texture.

- Chemical Industry: Can prepare multiple emulsions consisting of different chemicals, oils, and water soluble compounds to produce uniform stability emulsion for different industrial applications.

How It Works:

The emulsion mixer machine operates using high shear between rotor and stator to breakdown larger particles and fracture them into numerous smaller parts to microscopically disperse ingredients. This significantly aids in obtaining the desired consistency, suitable particle size, and fine texture on the product which is mainly useful to industries such as cosmetics and food processing where uniformity and appearance are prioritized.

Commonly Asked Questions (FAQs):

- 1. I am curious what would be the most suitable voltage for my emulsion mixer machine? The emulsifier mixer machine has scope ranging from 110V to 600V and you can choose what best suits your area.

- 2. Can the machine be modified for different viscosities? Yes, this machine is flexible. It may be set up with various motor speeds, mixing blades, and shear forces to cope with both low and high viscosity liquids.

- 3. What materials does the machine come in or are available? The emulsion mixer machine comes in two options, 316L or 304 stainless steel that are highly embrittled resistant to corrosion. 316L is preferred for tours that are severely corrosive while 304 is used for tour industries in the greater industrial region.

- 4. What power rating do emulsion mixers use? Power options vary from 1.5KW to 55KW depending on your production scale and requirements. High power options are available for the greater capacity emulsion mixer and for higher production lines.

- 5. Does the emulsion mixer have simple operations? Yes, the emulsion mixer has a straight forward and friendly user interface. It also has a control window, allowing the users to change parameters like mixing speed, time, and temperature. These can easily be changed by the user towards having the perfect mix.

- 6. Are there any sectors where an emulsion mixer machine is particularly useful? In the manufacture of cosmetics, pharmaceuticals, food and drinks, paints, coatings, or even chemicals, well formulated emulsions are vital, and the emulsion mixer machine is very useful in these industries.

Investing in an emulsion mixer machine guarantees consistent high quality emulsions on your production line. This machine has the versatility, dependability and accuracy that a business with food processing or cosmetics or industrial applications needs in order to grow.

Contact us now so we may talk about your specific needs and get the best emulsion mixer machine for your company.