1000 liter mixing tank

- Capacity: 50 liters to 30,000 liters

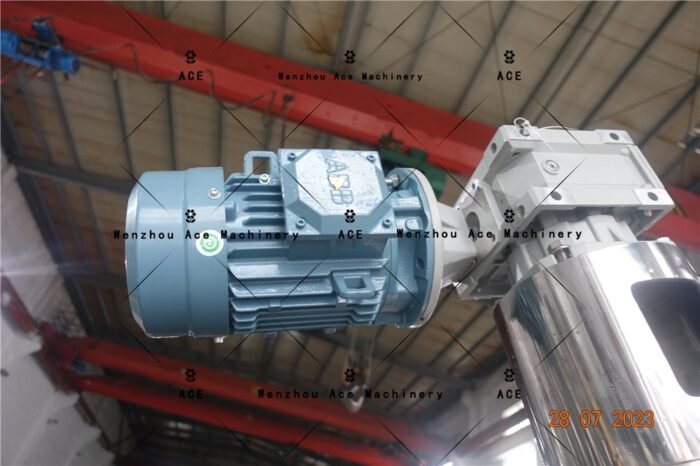

- Mixer power: 1.5 kW to 55 kW

- Material: 304 or 316L

- Voltage: 110V to 600V

- Heating method: Electric or steam heating

- Layer:single/double jacket/three jacket

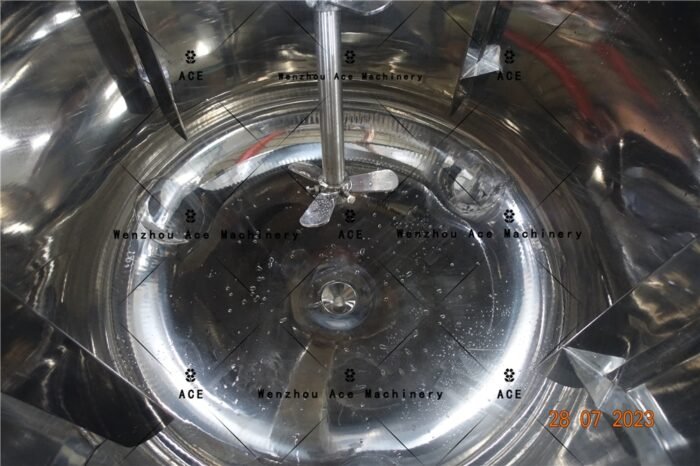

- Mixer types: Impeller-type, Anchor-type, Turbine-type, High-shear-type, Magnetic mixer, Anchor-type mixer with scrapers,dispersing

- Optional: platform, wheels, ladder,variable frequency drive,explosion-proof device

- Certificates: ASME, CE, GMP, UL, ATEX, ISO 9001

- Our equipment supports customisation, global delivery, and a 1-year warranty.

- If you have drawings, we can process them for you.

Note: Please contact our sales team before placing an order. Website prices are for reference only; specific pricing requires understanding your requirements to provide a quote.

Email:info@ace-chn.com

Tel: +86 186 2683 5909

WeChat: ace-chn

WhatsApp: +86 186 2683 5909

$3,400.00

Guaranteed Safe Checkout

Recommend RPM: 0-960RPM

Viscosity: Low/medium viscosity

Application: Mainly Liquid mixing

Recommend RPM: 0-200RPM

Viscosity: Low/medium viscosity

Application: Mainly Liquid mixing

Recommend RPM: 30RPM

Viscosity: Medium/High viscosity

Application: Melting, High viscosity product mixing, For single wall tank

Recommend RPM: 30RPM

Viscosity: Medium/High viscosity

Application: Melting, High viscosity product mixing, For jacket tank

Recommend RPM: 1480/2850 RPM

Viscosity: Low/medium viscosity

Application: Liquid powder mixing and dispersion

Recommend RPM: 1480/2850 RPM

Viscosity: Low/medium/High viscosity

Application: Liquid powder mixing and homogenizing

Recommend RPM: 0-355RPM

Viscosity: Low/medium viscosity

Application: Install at bottom, No mechanical seal working condition

Recommend RPM: As above

Viscosity: Low/medium viscosity

Application: Liquid powder mixing and dispersion For tank volume >300L

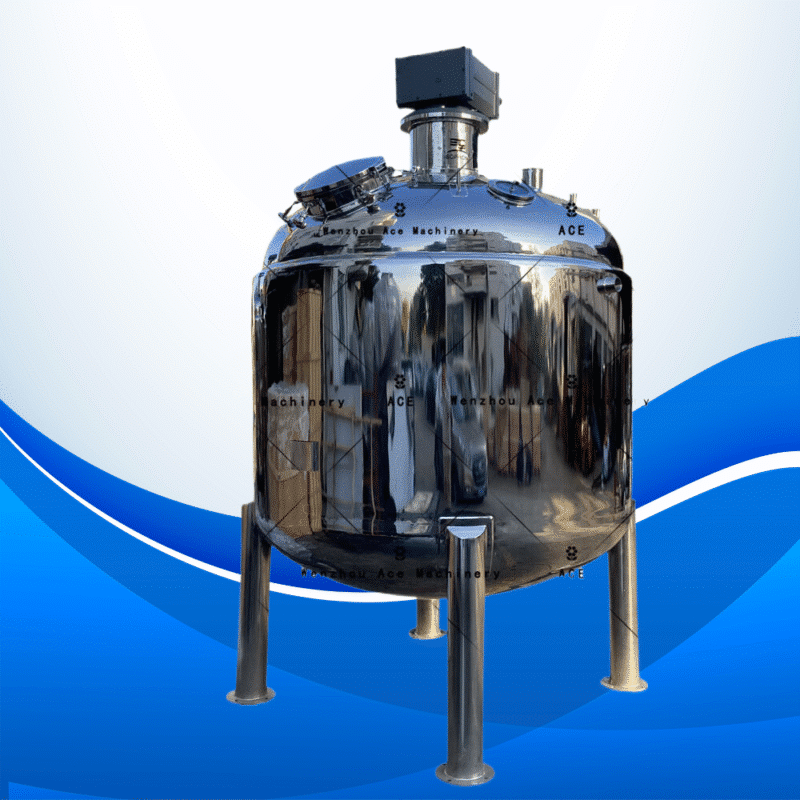

Efficiency, sturdiness, and precision are essential words that come to mind with industrial mixers. With the 1000 liter mixing tank, there is no more room for doubt if you are an organization that seeks to elevate its production standards. Whether for food and beverage, pharmaceuticals, chemicals, or cosmetic industries, this canister provides you with the necessary volume, reliability, and efficiency to maximize your mixing processes.

This tank boasts an able construction design that offers versatility, enabling it to mix liquids, semi-solids, and powders. Additionally, the large capacity provides better mixing even under high demand conditions, making it an important feature in any manufacturing setup.

Stand Out Features of the 1000 Liter Mixing Tank

Investing in a 1000 liter mixing tank adds to productivity in terms of efficiency and durability. Here are some standout features that make this tank a top choice for industrial applications:

Robust Construction

The inner wall of the tank is made using A-grade stainless steel, ensuring it is anti-corrosive and durable. The tank body is designed to withstand harsh chemicals, making it ideal for industrial use.

Wide Variety of Materials to Mix

This tank can handle liquids, powders, and viscous materials in various shapes and sizes. Its design allows for different mixing processes, making it ideal for various industries.

Efficient Agitator System

The tank has an efficient agitator system that allows for proper mixing of contents. The agitator system delivers consistent results, whether blending emulsions at high speeds or slow stirring for sensitive products.

Temperature Control Options

Industries such as pharmaceuticals and food processing can utilize the 1000 liter mixing tank with heating or cooling jackets for precise temperature control during the mixing process.

Easy to Clean

Hygiene is essential in food and drug industries. The tank’s clean-in-place (CIP) systems allow the interior to be cleaned effectively without disassembly, saving time and meeting health and safety requirements.

Applications of the 1000 Liter Mixing Tank

Thanks to its large capacity and high versatility, the 1000 liter mixing tank finds applications in various industries:

Pharmaceuticals

This tank is suitable for mixing liquid solutions, suspensions, and syrups in bulk quantities. It is well-suited for industries requiring temperature control and easy cleaning.

Food and Beverage

Whether mixing sauces, beverages, or dairy products, this tank provides the required capacity and efficiency to handle high-demand production while maintaining product quality.

Chemical Processing

Designed for use with chemicals, paints, and industrial liquids, the tank’s robust structure ensures the complete mixing of difficult materials.

Cosmetics

The 1000 liter mixing tank is commonly used in the production of lotions, shampoos, creams, and other cosmetic products, providing evenness and consistency over large quantities.

How the 1000 Liter Mixing Tank Changes the Game

The 1000 liter mixing tank increases operational efficiency, enabling companies to be more productive during production. Here’s how it delivers on its promises:

Consistent Mixing

The efficient and powerful agitator ensures consistent mixing of materials, eliminating the inconsistencies often seen in smaller, less efficient tanks.

Reduced Downtime

With its large capacity, the tank allows for fewer production interruptions, reducing the need for multiple intermediate batches.

Enhanced Productivity

The tank is designed for efficiency, leading to faster mixing and shorter turnaround times, enhancing production levels and streamlining processes.

Improved Product Quality

When producing large quantities, maintaining consistency is critical. The 1000 liter mixing tank ensures similar quality products, improving customer satisfaction.

Frequently Asked Questions

What is the construction material of the 1000 liter mixing tank?

Our 1000 liter mixing tank is made of strong, corrosion-resistant stainless steel that is easy to maintain.

Can the tank handle high-viscosity materials?

Yes, the tank is designed to mix high-viscosity materials such as creams, gels, and thick liquids, thanks to its strong agitator system.

Can the tank be customized to meet specific industry requirements?

Yes, the 1000 liter mixing tank can be customized with features like temperature control jackets, various agitators, and CIP systems to meet industry-specific needs.

What is the procedure for cleaning the 1000 liter mixing tank?

The tank has a built-in clean-in-place (CIP) system that allows for effective cleaning without disassembly, addressing hygiene concerns without causing downtime.

Which industries are most likely to employ the 1000 liter mixing tank?

Due to its large volume, durability, and versatility, this tank is widely used in the food and beverage, pharmaceutical, chemical, and cosmetic industries.

Is the tank portable?

While the standard design is fixed, we offer versions with wheels or casters to allow for easy movement around your production facility.

Our 1000 Liter Mixing Tank: What Makes It Stand Out

The 1000 liter mixing tank can significantly improve production processes. It is capable of mixing various materials effectively, including sensitive food ingredients and aggressive chemicals. With stainless steel construction, a high-torque agitator, and customizable options, it is a long-term investment for companies that demand high performance.

Its clean design minimizes downtime, resulting in higher productivity levels for your business.

Call to Action: Make an Investment in a 1000 Liter Mixing Tank Today!

Are you looking to enhance your output seamlessly? Our 1000 liter mixing tank is ideal for intensive and thorough mixing in various industries. Stop using inefficient machinery that hinders your operations and opt for a quality mixing tank instead. Contact us today to learn more about how our tanks can benefit your business!