Batch Mixers vs In-line Mixers for High Shear Processes

High Shear Mixing Overview

What is High Shear Mixing?

High shear mixing is simply the vigorous mechanical mixing of components in order to disperse, emulsify or homogenize them. This is achieved through turbulent high shear rates which guarantee even mixing of particles and the formation of constancy of mixtures. This also employs thermos-acoustic and high energy methods to accomplish. This process is crucial for such applications where a smooth surface, an even consistency or a desired state of a product is necessary.

Major Benefits of High Shear Mixing

- Reduction of Particles Size: Assists in achieving finer particle size for texture enhancement.

- Improved Emulsification: Enables liquid to be transformed into various stable emulsions, such as Mayonnaise.

- Enhanced Product Consistency: Enables to achieve consistent concentration and reduces the variability during batches.

- Saves Time: Shows improvement in pumping cycles compared to other methods.

Key Applications for High Shear Mixers

High shear mixers are used in many industries, such as pharmaceuticals, for the mixing of active components during the preparation of tablets and creams. Fats that are very viscous can be blended, as found in sauces, dressings, and emulsified beverages, using mixers in the food and beverage industry. Creams, lotions, and gel-based products that require consistency can also be created using high shear mixers, along with the mile-en-place of sealants, adhesives, and emulsified chemicals.

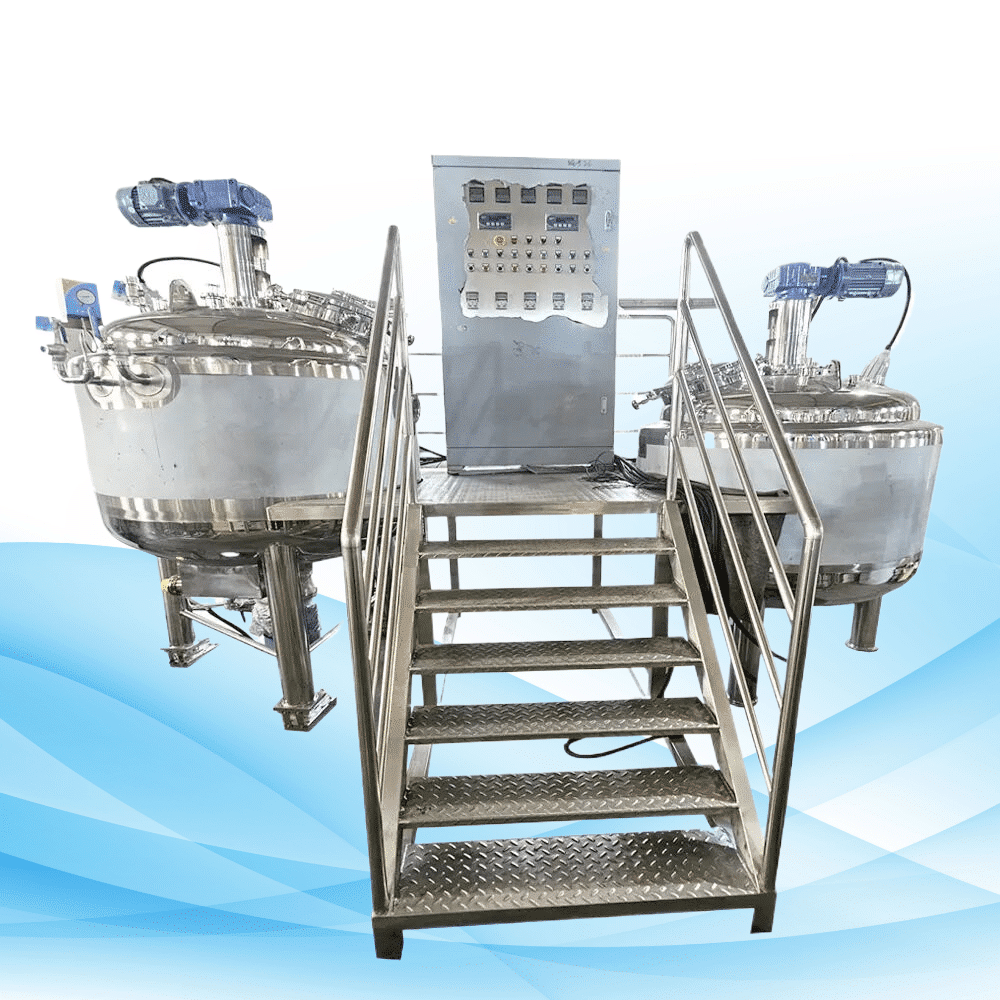

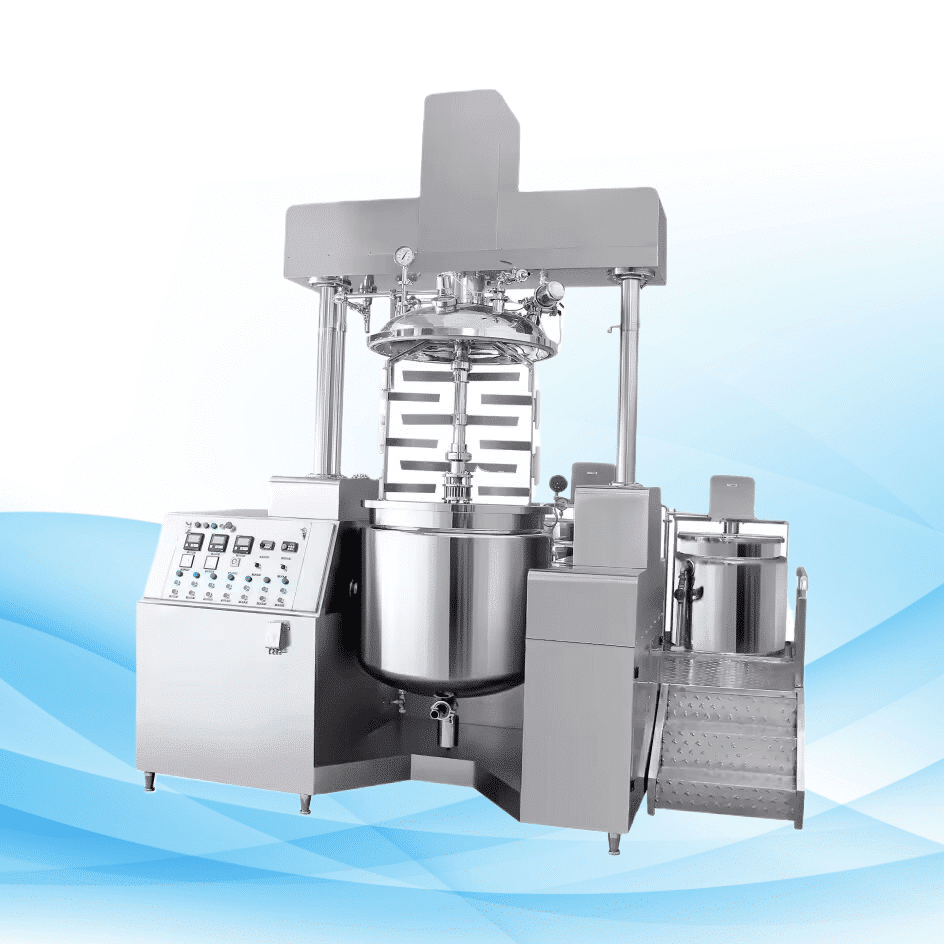

Batch Mixers

Are there any working principles for Batch Mixers?

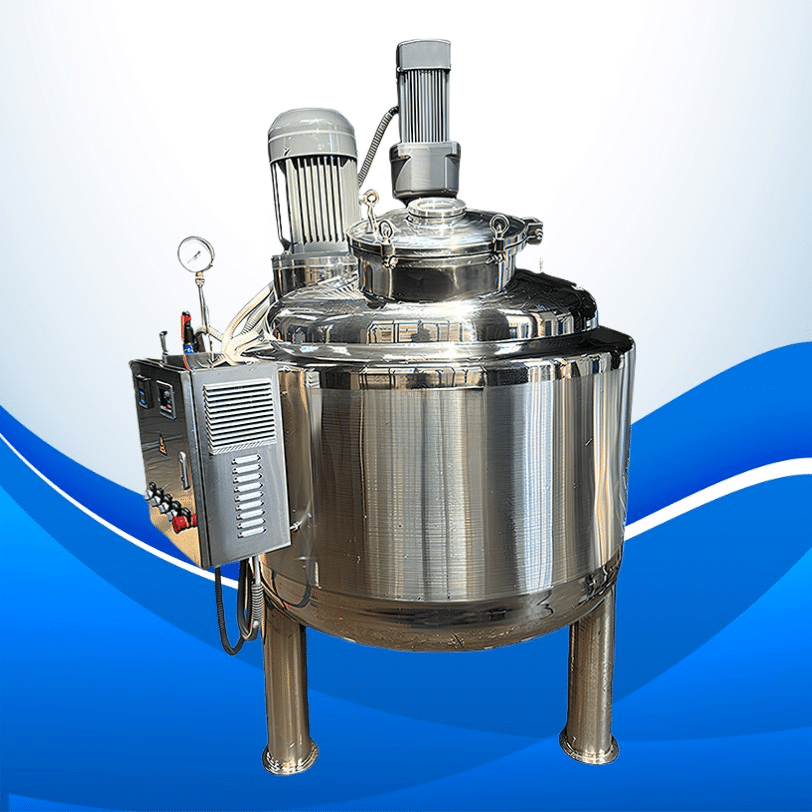

Batch mixers function using a high-speed rotor stator or an impeller inside a stationary container, the rotors and stators apply shear blending to the mixture and the end result is a blend with a certain consistency, as batch mixers contain no moving parts, the mixing process is not continuous. Both manual and mechanical techniques are used to add items, stir, and remove them from the mixer.

How are Batch Mixers advantageous?

There are certain benefits that batch mixers provide that are very distinct. They include:

- Flexibility: They are best suited when smaller quantities of customized products are needed.

- Precision: The mixing time and conditions need to be controlled during the process, so the operators try to have the best conditions and the final product looks appealing.

- Testing Ease: The products that were under research alongside the products at a pilot stage were produced and tested within batch mixers alongside a smaller amount of the material being used for production.

What are the Limitations of Batch Mixers?

In spite of all the advantages these mixers provide, there are certain limitations batch mixers present; these include:

- Lower efficiency as compared to the continuous systems.

- Time when mixing as items are added in a sequential form and then removed in that order too.

- High volume productions are not possible within the batch mixers.

Typical Applications of Batch Mixers

- Cosmetic industry: During the production of creams and lotions in smaller amounts.

- Compounding of specialty medications is the business of pharmacies.

- Production of gourmet sauces and dressings is also the business of food mongers.

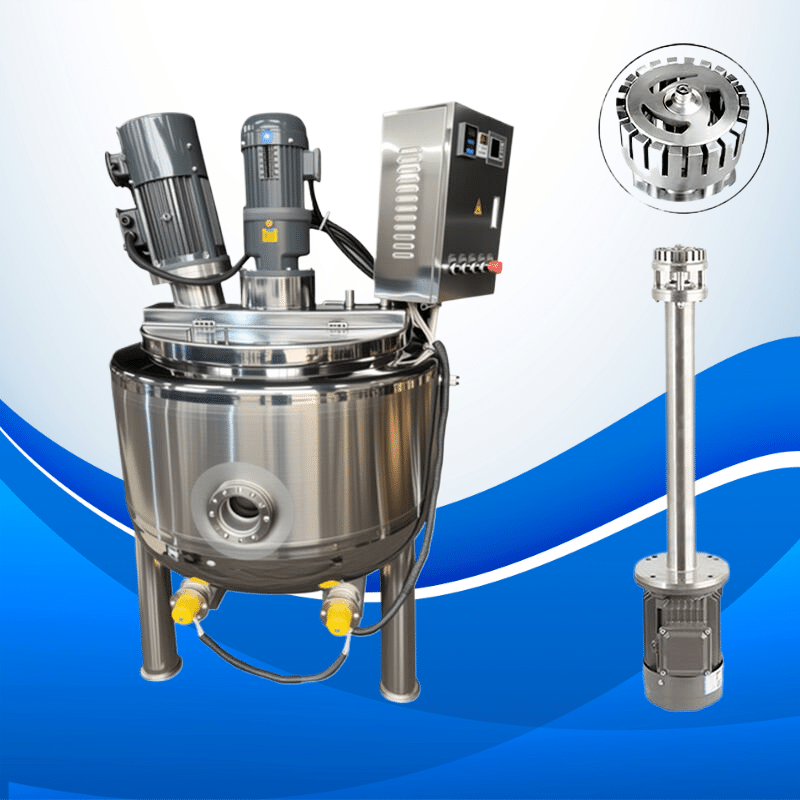

Application of In-line Mixers

How In-line Benders Work

In-line mixers are said to be pipeline machines which do not stop as long as there exist materials to be processed. As the materials are conveyed into the mixing section of the machine, a rotor-stator assembly exerts very high shear stresses on the materials. The process is efficient and the quality of the product is simultaneous with the time of production.

Benefits of Inline Blenders

- Ability to Produce More: As the equipment is meant for nonstop functioning, mass production is easier.

- Quality Assurance: Prevents variability within and between the raw materials from batch to batch.

- Reduction of Space: The compact dimension design allows room for an elegant integration into the production facility.

- Automated: Connect automatically to systems.

Disadvantages of Inline Benders

- Less flexible: Constraining when changing recipes frequently.

- Initial Investment: More expensive than batch mixers.

- Complex Cleaning: Often requires cleaning-in-place (CIP) systems.

Usual Uses of In-Line Mixers

- Food industry & beverages: Preparation of sauces and beverages in bulk.

- Utilization of creams or liquid formulations on a lean basis in the pharmaceuticals’ industry.

- Emulsions and dispersions produced in bulk to model for chemicals.

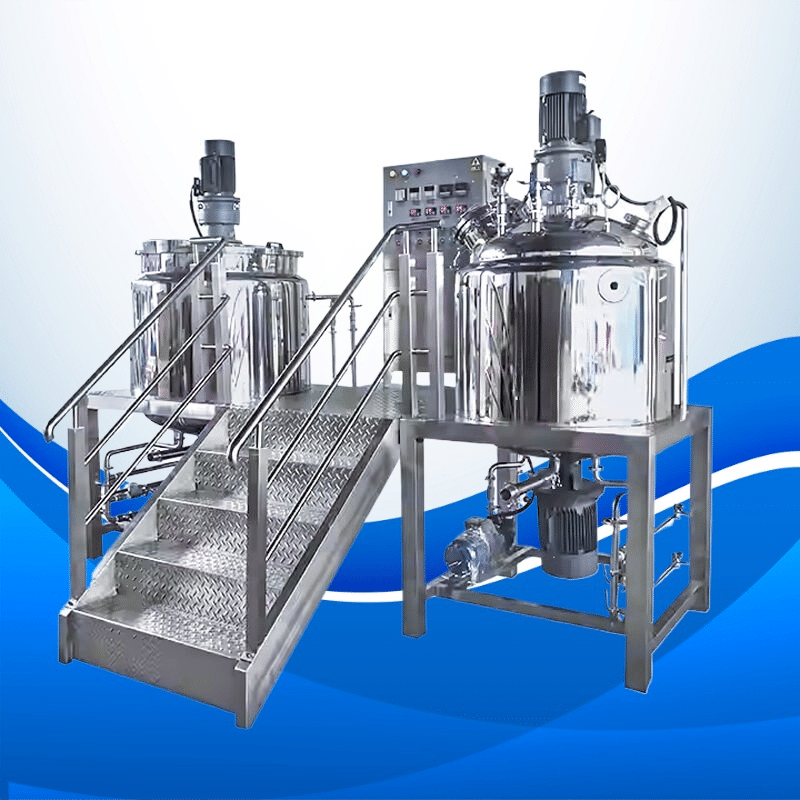

In-plant Comparison Between a Batch Mixer with an In-line Mixer

Productivity And Turns Out

Batch Mixers Recording: Output is low as they rely on sequential operation and work best during small scale or made-to-order batches.

Inline Mixers

This type of mixer guarantees reduced operating space during the process of high shear mixing, as well as allows for continuous operational processes. The in-line mixer produces high output while also maintaining high shear mixing. This guarantees that all requirements for high throughput will be met with little to no beating to make sure emulsifying and blending is done.

Batch Mixers

Batch mixers operate at their best during low scale production or when the bare minimum precision is required, making them ideal during R&D and for specialty goods such as cosmetics or pharmaceuticals. The batch mixer smoother any specification for low-speed emulsions as requires max precision now and then.

Food and Chemical Manufacturing Process

Food and chemical manufacturers are involved in a mass production process and consistency is key. Inline mixers allow efficiency improvements, with every additional push providing stability in the long run. So in short, there are no limitations to the in-line mixer.

Conclusion

In conclusion, when dealing with small scale operational or low-speed emulsifying, batch mixers are your best friend in assuring a low margin of error. On the other hand, in case efficiency and productivity are the main goals, then high throughput inline mixers are the tool to use.

While picking among them, keep in consideration factors such as cost, need for the process, production volume, and requirements specific to your industry. So long as you base your selection on your operational targets, it will guarantee that you have the best performance and product quality.