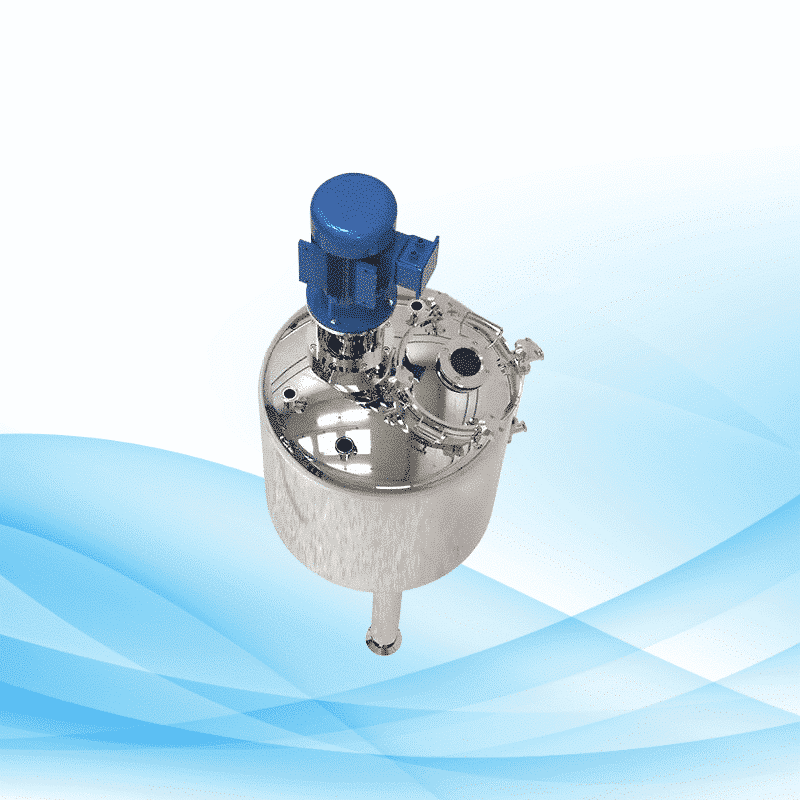

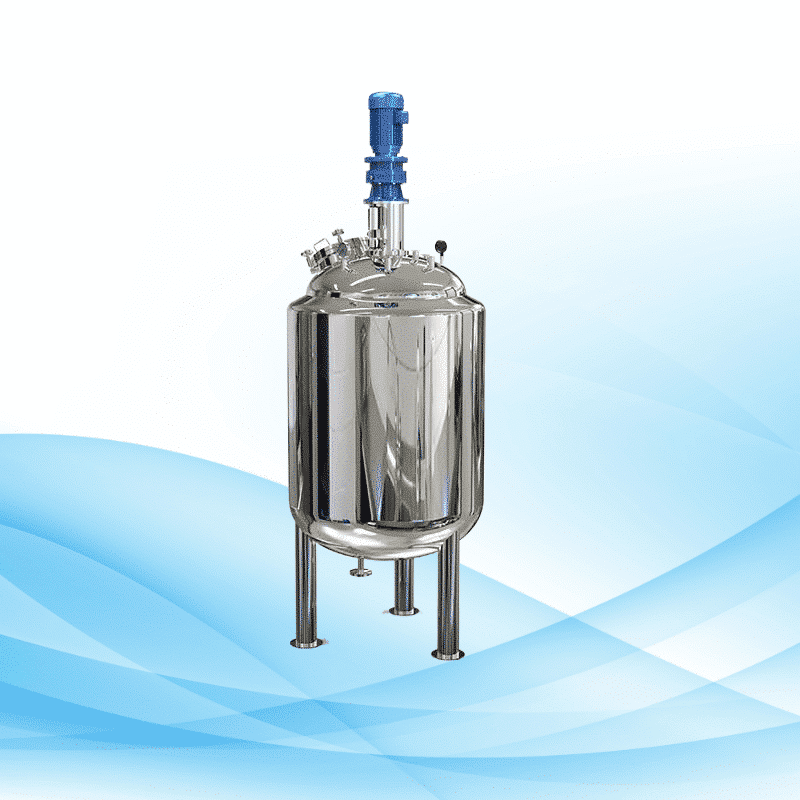

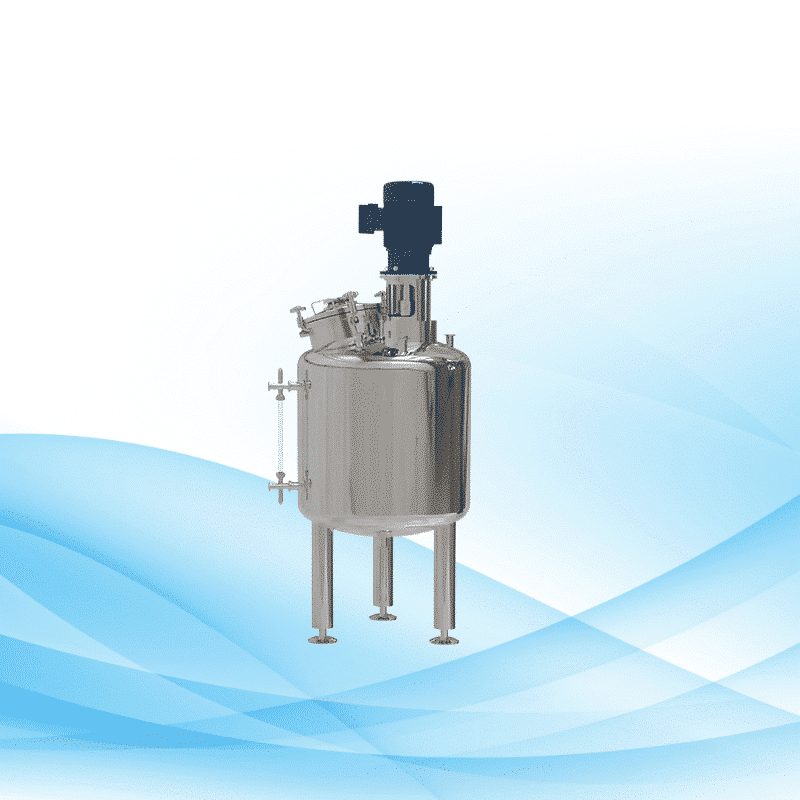

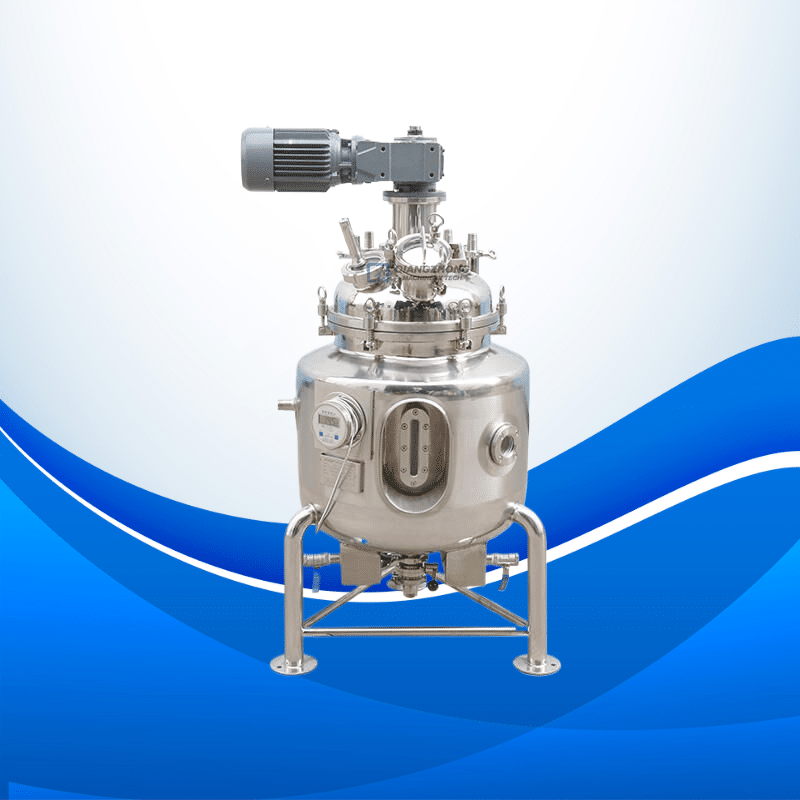

To meet the best benchmarks of quality and performance, this 100 gallon mixing tank has been designed with great skill. It is therefore perfect for industries that require accurate heating and mixing solutions. This container is built out of either premium grade 304 or 316L stainless steel which guarantees durability, easy maintenance due to corrosion resistance among other things, making it reliable in different applications.

Key Features

- Material Options: The tank can be made from either 304 or 316L stainless steel which provides better resistance to corrosion than any other material used for this purpose so far, even under harsh conditions.

- Heating Options: The tank is designed in such a way that it supports both steam and electric heating systems, since its creators wanted to ensure versatility during their design process. You will therefore select the option that suits your operational needs, whether energy saving or faster warming.

- Scraper Agitator: With an efficient scraper agitator fitted on this particular type of vessel all contents are uniformly mixed preventing them from sticking onto walls thus assuring uniformity in final product quality.

- Level Gauge: A level gauge comes as part of its accessories, allowing one to monitor accurately liquid levels, hence precision control over production processes.

- CIP Cleaning Ball: To enable easy cleaning without disassembling anything thereby saving time as well reducing risks associated with contamination through touching dirty surfaces unnecessarily another feature included on tanks is CIP(Clean-In-Place)cleaning ball meant for thorough sanitization

- Sight Glass: An integrated sight glass affords users clear view into what is happening inside these containers while mixing substances together so they can keep track of progress being made at any given instant during operation time when everything seems static one may think nothing much going on there only if he could peep through such a window like opening somewhere near top surface then most likely discover otherwise hidden truths about system dynamics taking place beneath his very eyes.

- Manhole: In order not only ease inspection but also facilitate manual addition of ingredients for those who prefer doing things manually sometimes without necessarily having to use any sophisticated equipment

Applications:

This 100-gallon mixing tank is versatile hence can be used in various fields such as food & beverage, pharmaceuticals industry cosmetics manufacture and chemical industries… It performs well when it comes to blending processes; emulsifying agents production; homogenization procedures as well as temperature sensitive operations among others, hence assuring products meet the highest standards possible.

Why Choose Our 100 Gallon Mixing Tank?

Purchasing our 100-gallon mixing tank means one will have opted for reliability, efficiency plus high performance. This container was built with current industrial needs taken into account, thereby comprising top quality materials, advanced features blended together with numerous uses. Therefore, improve on your production process while maintaining uniformity by using this latest model mixer.

Order Now Today!

Don’t just sit there watching others succeed through their great mixing capabilities, contact us today itself concerning more details about this device so that you may also make an order now. Try out our machines, which are different from the rest in terms of both quality and working speed!