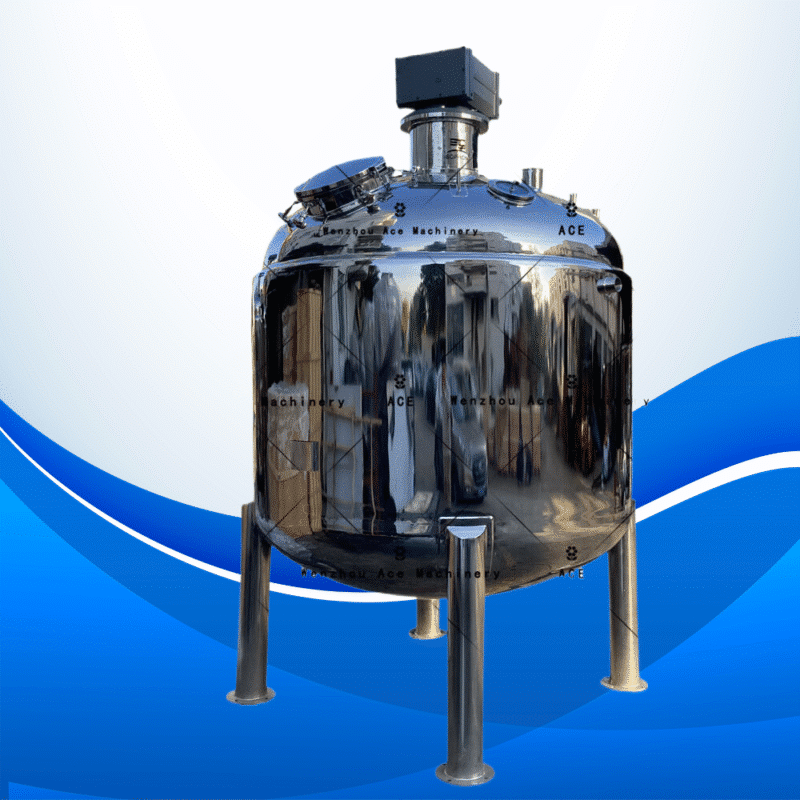

Mixing Tanks with Agitator

- Capacity: 50 liters to 30,000 liters

- Mixer power: 1.5 kW to 55 kW

- Material: 304 or 316L

- Voltage: 110V to 600V

- Heating method: Electric or steam heating

- Layer:single/double jacket/three jacket

- Mixer types: Impeller-type, Anchor-type, Turbine-type, High-shear-type, Magnetic mixer, Anchor-type mixer with scrapers,dispersing

- Optional: platform, wheels, ladder,variable frequency drive,explosion-proof device

- Certificates: ASME, CE, GMP, UL, ATEX, ISO 9001

- Our equipment supports customisation, global delivery, and a 1-year warranty.

- If you have drawings, we can process them for you.

Note: Please contact our sales team before placing an order. Website prices are for reference only; specific pricing requires understanding your requirements to provide a quote.

Email:info@ace-chn.com

Tel: +86 186 2683 5909

WeChat: ace-chn

WhatsApp: +86 186 2683 5909

$4,500.00

Guaranteed Safe Checkout

Recommend RPM: 0-960RPM

Viscosity: Low/medium viscosity

Application: Mainly Liquid mixing

Recommend RPM: 0-200RPM

Viscosity: Low/medium viscosity

Application: Mainly Liquid mixing

Recommend RPM: 30RPM

Viscosity: Medium/High viscosity

Application: Melting, High viscosity product mixing, For single wall tank

Recommend RPM: 30RPM

Viscosity: Medium/High viscosity

Application: Melting, High viscosity product mixing, For jacket tank

Recommend RPM: 1480/2850 RPM

Viscosity: Low/medium viscosity

Application: Liquid powder mixing and dispersion

Recommend RPM: 1480/2850 RPM

Viscosity: Low/medium/High viscosity

Application: Liquid powder mixing and homogenizing

Recommend RPM: 0-355RPM

Viscosity: Low/medium viscosity

Application: Install at bottom, No mechanical seal working condition

Recommend RPM: As above

Viscosity: Low/medium viscosity

Application: Liquid powder mixing and dispersion For tank volume >300L

Mixing tanks with agitators have significant importance in a variety of industries. The consistent texture of a product is guaranteed with the help of these tanks, whether it is in regard to processed foods or chemicals or pharmaceuticals. These tanks are fitted with varieties of agitators and these tanks are tailorized to solve specific mixing problems of specific industries.

When companies want to mix, blend or homogenize liquids, it is essential that they have access to a suitable mixing tank with an appropriate agitator. This has been made possible with the right combination of agitators and tanks which translates to companies enjoying faster processing rates and in the end, better product efficiency.

Key Features of a Mixing Tank with Agitator

Sturdy Construction

A mixing tank is an industrial container generally fabricated using hard materials such as stainless steel, which allows the tank to endure harsh chemicals and extreme temperatures. By considering such factors, the in service life of the equipment is increased and at the same time the equipment is still able to meet health standards, especially for food and pharmaceuticals applications.

Efficient Agitation

The mixing tank has the agitator as an essential part. It secures the proper distribution of the materials inside. Several types of agitators can be built, including paddle, turbine, and propeller type fashions. Choosing the right one based on the viscosity and density of the materials can greatly shorten mixing times and energy usage.

Customizable Design

Mixing tanks with agitator systems can be designed to clients’ specifications including those relating to the dimensions of the tank, shape of the agitator, use of jackets designed for heating or for insulation purposes among other things. Customization helps in making sure that every tank is designed and constructed for specific applications of the process, which help in improving outcome.

Temperature Control

For mixing tanks with the stirring devices which have jacketed structures, consequently are able to attach heat sources or cooler devices to the tank. This is essential industry both in pharmaceuticals and cosmetics, when mixing is done at a specific temperature And the temperature is very important when mixing.

Industries That Benefit from Mixing Tanks with Agitators

Food and Beverage

Consistent mixing is undoubtedly one of the critical process factors in the manufacture of sauces, dairy products, beverages, etc since it aids in achieving proper proportions of the blend components. Agitators guarantee that the ingredients are mixed in the right amounts for uniform flavors and textures.

Pharmaceutical

On the other hand, drugs, ointments and creams can be produced with more active ingredients when use of mixing tanks since they are used during the process of combining excipients with active ingredients to make them continuous.

Chemical Processing

Whether it’s paint, adhesive, or detergent formulation, some chemical processes always imply the mixing of the high viscosity liquids which one can achieve by correctly designing an agitator.

Cosmetics

During the production of cosmetics, the processes mixing tank is used to achieve integration of creams, lotions and other personal care products: the content is put into the mixer or emulsifier, which ensures uniformity of the end product from each composition for texture and quality.

Customization and Installation

As it is already stated in the previous paragraph, when selecting a mixing tank with an agitator, customization is important. A unit of inflating business often requires not only circumcision to about the size of test tubes, but also the possibility of increasing the volume through the use of mixes with a capacity ranging from zero to the upper limit defined by the neck of the vats. Also, important are a combination of importance and interdependence between the conditions of the fluid, whereby the fluid in the mix has viscosity, the required rotation speed of the fluid mix, and composition constituents.

Customization may include some of the following options, which include;

- Tank Volume: Small scale and large industrial scales

- Material: stainless steel 304 316L or other more exotic materials

- Agitator Type: Incorporate a paddle, anchor, or turbine Agitators

- Temperature Control: Jacketed vessels set for heating or cooling, as required by the process

- Additional Equipment: Sensors, control panels, and clean-in-place systems are available options.

Frequently Asked Questions on Mixing Tanks with Agitators

What type of mixing tank does an agitator attach to?

The most suitable type depends on the viscosity of the mixed material and the speed of mixing. Paddle type agitators perform better with mixing low viscosity liquids, whereas turbine type is better for mixing high viscosity materials like creams or slurries.

Can I design a mixing tank to my specifications?

Yes, it is very much possible to do that – but some factors will have to be considered first before any alterations are made in the design of a standard mixing tank with an agitator. These could include the dimensions to be used, which may include the material of construction along with the type and range of agitators that needs to be incorporated along with other additional features in order to make it specific for the required process.

How should a mixing tank equipped with an agitator be disinfected?

Another feature, which many tanks have and supersede these limitations, is the Use of CIP (Clean-in-place) systems, which makes things a lot easier and more efficient. These systems offer automatic cleaning while the machine is still assembled and therefore do not require the definition of ‘overhauling’ meaning breaks can be cut short between the production cycles.

What materials are mixing tanks made of?

Mixing tanks mostly are made of stainless steel, as it is a strong metal with the ability to withstand a lot of corrosion. For industries that have other material requirements, other types of metals and possibly any coatings may be supplied.

Invest in a Mixing Tank with Agitator Today!

The improvement in your production, reduction in costs and maintenance of quality of the end product can all be achieved by selecting the best mixing tank with agitator. The selection of the right equipment goes a long way in ensuring good results irrespective of the industry whether it is food, chemicals, pharmaceuticals and others.

Is your organization ready to boost mixing efficiency? If yes, call us today for more information about our bespoke mixing tank with an agitator and how it can solve your business requirements!