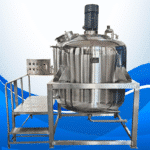

High-Performance Liquid Mixing Tank with Agitator

- Capacity: 50 liters to 30,000 liters

- Mixer power: 1.5 kW to 55 kW

- Material: 304 or 316L

- Voltage: 110V to 600V

- Heating method: Electric or steam heating

- Layer:single/double jacket/three jacket

- Mixer types: Impeller-type, Anchor-type, Turbine-type, High-shear-type, Magnetic mixer, Anchor-type mixer with scrapers,dispersing

- Optional: platform, wheels, ladder,variable frequency drive,explosion-proof device

- Certificates: ASME, CE, GMP, UL, ATEX, ISO 9001

- Our equipment supports customisation, global delivery, and a 1-year warranty.

- If you have drawings, we can process them for you.

Note: Please contact our sales team before placing an order. Website prices are for reference only; specific pricing requires understanding your requirements to provide a quote.

Email:info@ace-chn.com

Tel: +86 186 2683 5909

WeChat: ace-chn

WhatsApp: +86 186 2683 5909

$4,480.00

Guaranteed Safe Checkout

Recommend RPM: 0-960RPM

Viscosity: Low/medium viscosity

Application: Mainly Liquid mixing

Recommend RPM: 0-200RPM

Viscosity: Low/medium viscosity

Application: Mainly Liquid mixing

Recommend RPM: 30RPM

Viscosity: Medium/High viscosity

Application: Melting, High viscosity product mixing, For single wall tank

Recommend RPM: 30RPM

Viscosity: Medium/High viscosity

Application: Melting, High viscosity product mixing, For jacket tank

Recommend RPM: 1480/2850 RPM

Viscosity: Low/medium viscosity

Application: Liquid powder mixing and dispersion

Recommend RPM: 1480/2850 RPM

Viscosity: Low/medium/High viscosity

Application: Liquid powder mixing and homogenizing

Recommend RPM: 0-355RPM

Viscosity: Low/medium viscosity

Application: Install at bottom, No mechanical seal working condition

Recommend RPM: As above

Viscosity: Low/medium viscosity

Application: Liquid powder mixing and dispersion For tank volume >300L

Liquid Mixing Tank with Agitator: A Solid Choice for Smooth Blending

If your factory regularly needs to mix large amounts of liquid, a tank with a built-in agitator is hard to beat. Also, no matter whether you run a juice line, a chemical plant, a pharmacy, or even a lotion shop, the right setup can speed up work and bump up quality. Engineered to deal with everything from gentle stirring to full-throttle chemical reactions, this gear gives you the reliability you need on the shop floor.

Key Advantages of a Liquid Mixing Tank with Agitator

Keen Mixing Power

These tanks are made for one job: making sure every drop, powder, and tiny particle gets blended and stays blended. Thanks to the shape of the paddle, impeller, or turbine inside, materials meet each other quickly instead of settling in layers. The upshot is a smoother product, less guesswork between batches, and the on-the-money results that matter when precision really counts.

Wide Range of Applications

This mixing tank is suitable for diverse industries, including:

- Chemical Processing: For emulsifying, dissolving, or homogenizing chemicals and solvents.

- Pharmaceutical Production: Perfect for mixing active ingredients and excipients for medicines or ointments.

- Food and Beverage: Ideal for mixing liquids like sauces, soups, or dressings.

Cosmetic companies count on our tanks to mix creams, lotions, and nearly any other liquid beauty product smoothly.

Customizable to Meet Your Needs

We know every business has its own setup, so each mixing tank can be fitted with features that match yours:

- Voltage Options: Pick a voltage from 110V to 600V, so you stay in line with local power supplies.

- Power Options: The mixer motor ranges from 1.5KW to 55KW, letting you choose exactly how much strength you need.

- Material Choices: Go with 316L stainless steel if you need top corrosion resistance, or 304 steel for everyday jobs, keeping hygiene high and repairs low.

High-Quality Construction for Longevity

Built from heavy-duty stainless steel, our tank-with-agitator shruggs off tough factory conditions. Whether you’re working with strong chemicals or food-safe liquids, the anti-corrosion design keeps everything performing well for years on end.

How It Works: The Liquid Mixing Process

Our mixing tank has a spinning shaft and curved blades that whip around and pull liquid toward the center, so everything tumbles together. By turning the speed up or down and swapping the blade shape, operators can match the setup to whatever slurry, syrup, or paste they work with.

Because the blades keep the liquid moving, they also chase out trapped air, help heat spread evenly, and dissolve solid chunks fast. That flexibility means the same machine can mix a fragile blend or smash fibers without damaging them.

Why Choose Our Liquid Mixing Tank with Agitator?

Precise Control

The speed dial lets you slow or speed up mixing in seconds, meaning light sauces and thick gels can both get the same uniform finish.

Energy Efficiency

Motors are sized to deliver only as much power as the job calls for, so electric bills stay lower even when production runs long.

Easy Maintenance

Swing-open panels and removable shafts ensure pumps and seals can be cleaned or replaced in minutes, keeping idle time to a real minimum.

Versatile Design

Our liquid mixing tanks can whip up everything from thin juice to thick syrup, so they fit in just about any setup that needs blending.

FDA Options

If you work in food or medicine, ask about our FDA-approved version; it clears all the safety rules you have to follow.

Common Uses for Liquid Mixing Tanks with Agitators

- Food and Beverage: jazz sauces, syrups, dressings, or any drink.

- Chemical Manufacturing: mix pigments, adhesives, or cleaning solutions.

- Cosmetic and Pharmaceutical: blend creams, lotions, and ointments.

- Water Treatment: prepare chemicals for purifying water or other green projects.

Product Specs

| Parameter | Details |

|---|---|

| Voltage Options | 110V, 230V, or 380V, up to 600V. |

| Power Options | 1.5 kW, 3 kW, 5.5 kW, and up to 55 kW. |

| Material Options | Food-grade 316L stainless steel or 304 SS. |

| Tank Size | Built-to-order, small bench tanks to big bulk volumes. |

| Agitator Type | Choice of paddle, impeller, or turbine. |

| Mixing Speed | Simple dial control or variable-speed motor. |

| Certification | Optional FDA-approved documents are available. |

Ordering Your Custom Mixing Tank

Every operation is different, so our design team works with you to nail down the right size, material, voltage, power, and any other options. Just send a message or call, and we’ll guide you through the choices step by step. Whether you need one unit for a lab or a truckload for a factory line, quality and value are our promise.

FAQs

Q: What is the smallest tank I can get?

A: We build tanks starting at 50 liters and can go up to several thousand liters, all to match your process.

Q: Can I pick my own agitator style?

A: Absolutely. Tell us your materials, and we’ll fit either a paddle, turbine, or impeller to get the mix you need.

Q: How do I keep the mixing tank in good shape?

A: The tank is made for quick clean-up. Just pop off the agitator, give the inside a wipe, and you’re done. If you want an even easier job, ask about our cleaning-in-place (CIP) option that does it automatically.

Q: Can I use this equipment in food production?

A: Absolutely. We make sure every part meets FDA rules, so you can feel good about using it in food and drink lines.

Q: Once I order a custom unit, how long until it shows up?

A: A one-of-a-kind unit usually leaves our shop in about 4 to 6 weeks, though the exact timing depends on the specs you choose.