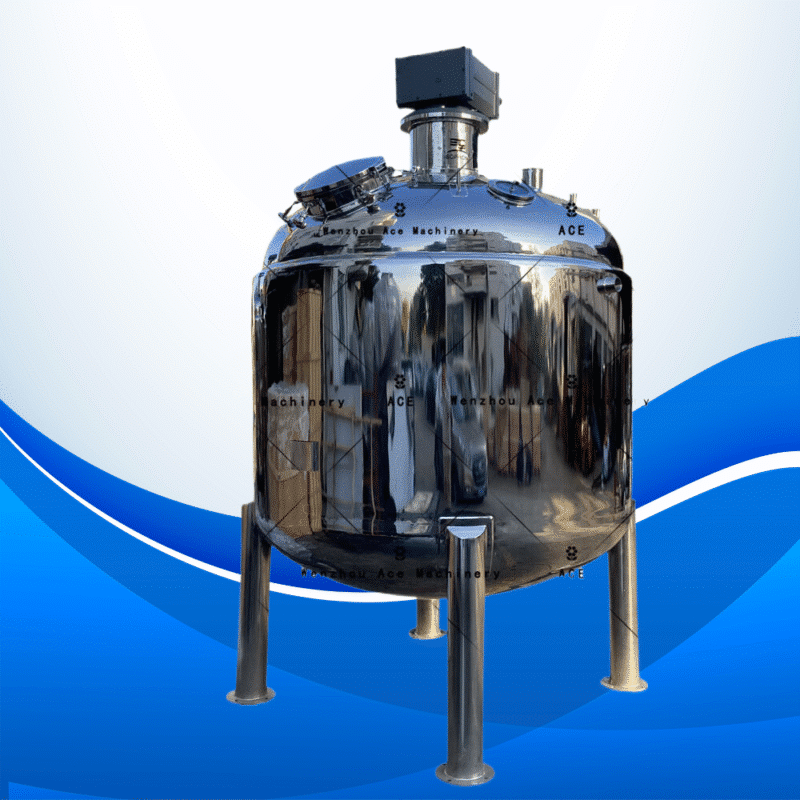

When factories need machines they can count on, the 1000-gallon stainless steel mixing tank often tops the list. From food plants to drugmakers, chemical outfits to beauty-product shops, this tough, roomy vessel gives crews the speed and strength they want to keep things moving.

Built to tackle almost any mixing job, the tank’s shining stainless shell means operators worry less about scratches or residue. Whether pouring in liquids, grains, or fine powders, the one-thousand-gallon beast spins everything together with impressive uniformity. A quick look at its features, perks, and everyday uses shows why so many plants set it at the center of production.

Key Features and Benefits of the 1000-Gallon Mixing Tank

1. Tough, Corrosion-Resistant Build

Made from premium stainless steel, the one-thousand-gallon tank does not bend or rust easily, even after years of use. Customers choose between 316L and 304 grades, each crafted for different working conditions. 316L shines in jobs that mix aggressive acids, salts, or high-heat liquids, while 304 suits milder recipes like standard juices, cleaners, or creams.

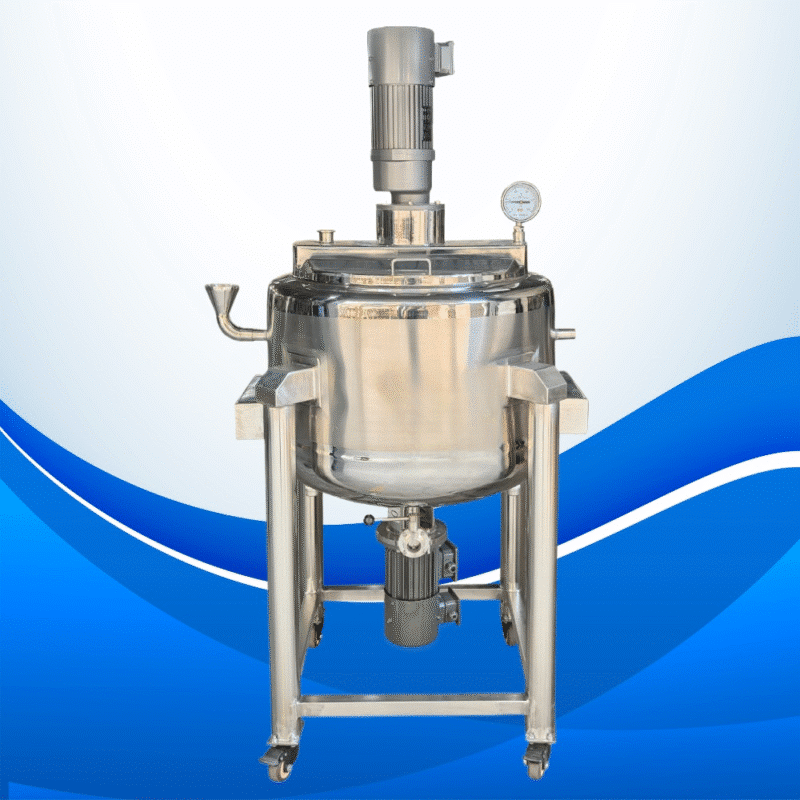

2. Adjustable Power Options

Built for people who need flexibility, this mixing tank lets you pick the power level that fits your job. The motor comes in sizes from a modest 1.5 kW up to a heavy-duty 55 kW, so whether you are whipping up a small test batch or running a big production line, you always have the right muscle.

3. Voltage-Friendly Design

You can order the 1,000-gallon stainless-steel tank wired to work at almost any voltage-between 110 V for smaller shops and 600 V for larger industrial grids. Because of this wide range, the tank drops right into your current setup, no costly upgrades or headaches. You can plug it in with confidence, knowing the equipment will pull power efficiently where-ever you are.

4. Mix-and-Match Agitation

The tank’s adaptability doesn’t stop with power. You can swap out the agitator for paddle whiskers, anchor blades, or high-shear rotors, choosing the best tool for your recipe whether it’s thick syrup, dusty powder, or watery slurry. Being able to fine-tune the mixing hardware means you get consistent results, batch after batch.

5. Clean and Easy to Look After

When factories work with food or medicine, keeping everything super clean is a top worry. A stainless-steel tank is quick to wipe down, so workers spend less time on scrubbing and more time on making. Its flat walls and sealed joins also stop dirt and germs from hiding, giving extra peace of mind in places that must follow strict rules.

Uses of the 1000-Gallon Stainless-Steel Mixing Tank

The 1,000-gallon mixing tank finds a home in many factory floors, helping each team blend, heat, or cool what they need without fuss. Here are some of the biggest job sites you will see it.

1. Food and Drink Plants

Food makers lean on this tank when they whip up sauces, spreads, jams, drinks, or dairy goodies. Because it cleans so easily, flavor and safety stay high from start to finish, and a motor that can speed up or slow down gives every recipe the right feel. Take juice lines: the tank mixes fruit purée, water, and sweetener until the drink is smooth and ready to pack.

2. Pharmaceutical Manufacturing

Drug makers call on the 1,000-gallon stainless steel mixing tank because it mixes suspensions, emulsions, or clear solutions with dependable precision. Active ingredients, excipients, and solvents travel through the tank together, so every particle must stay untouched. A smooth stainless surface acts like a careful shield, blocking contamination or chemical breakdown from ever happening.

3. Chemical Processing

Paint plants, glue factories, and coating lines all trust the same 1,000-gallon tank when they need to blend tricky chemicals. Thanks to stainless steel that laughs at rust and shrugs off bad reactions, the mixer holds up season after season full of acids, harsh alkalis, or sharp solvents.

4. Cosmetics Production

Lotion shops and cream makers reach for the big tank whenever a batch of shampoos, body butters, or self-tanners is too large for a tabletop mixer. Adjustable motor strength and changing stir speeds tuck every ingredient into the mixture, while the tank’s cleanable design never fails to meet strict beauty-factory rules.

Why pick the 1,000 Gallon Stainless Steel Mixing Tank?

Out of all the mixing vessels on the market, the 1,000-gallon stainless steel tank stands out for several practical reasons:

- Built to Last: Because it’s made from heavy-duty stainless steel, this tank won’t rust or warp; you can count on it running for years with only routine checks.

- Custom-Friendly Power: Order it with the motors, voltages, and connectors that match your shop floor; whether you’re blending liquids, dry powders, or thick pastes, it adapts easily.

- Faster Mixing Times: A strong, evenly distributed stir helps knock out bubbles and streaks in record time, speeding up each batch and keeping quality locked in with every pour.

- Cleanup Is a Breeze: Rounded corners, polished walls, and no sharp seams let a hose or quick CIP system scrub the entire interior, protecting products from germs in food or pharma lines.

Take the next step: Get Your Tailored 1,000 Gallon Stainless Steel Mixer Now

Upgrade your line with this tough, flexible tank, and you’ll boost capacity while meeting tight schedules. Order today, tell us your specs, and we’ll deliver a mixer built for the way you work.

Don’t wait—an experienced team member is ready to give you a custom price and show how this tank can streamline your operation.

Frequently Asked Questions (FAQ)

1. What material is the 1000-gallon stainless steel mixing tank made of?

The tank comes in 304 or 316L stainless steel. Use 316L in rough conditions or with strong chemicals; 304 works well for everyday tasks.

2. What voltage options are available for the mixing tank?

We can set the tank to run on any voltage from 110V to 600V, so it matches your facility’s electric system.

3. What motor power is offered for the mixing tank?

Choose a motor from 1.5 kW up to 55 kW, so you get just the right strength for your mixing job.

4. How do I clean the mixing tank?

The smooth stainless surface keeps cleaning fast and easy. Just wipe it with the right solvent, and you’ll keep the tank sanitary.

Absolutely, we can make the tank work just the way you need it. You pick everything, from the material and agitation style to motor strength and voltage, and we’ll build it for your production line.