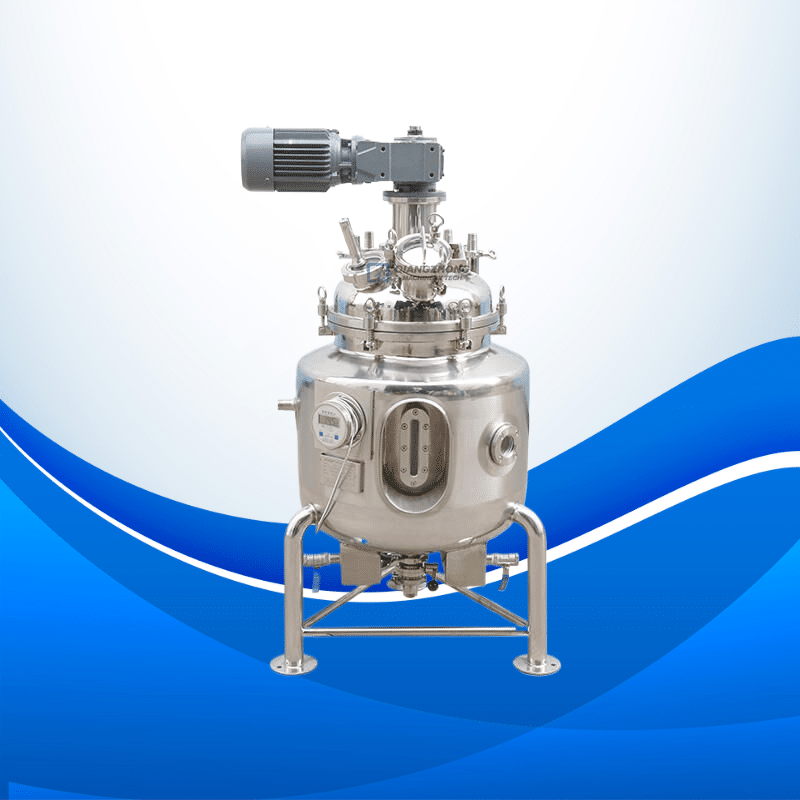

High-Performance Heated Mixing Tank

- Capacity: 50 liters to 30,000 liters

- Mixer power: 1.5 kW to 55 kW

- Material: 304 or 316L

- Voltage: 110V to 600V

- Heating method: Electric or steam heating

- Layer:single/double jacket/three jacket

- Mixer types: Impeller-type, Anchor-type, Turbine-type, High-shear-type, Magnetic mixer, Anchor-type mixer with scrapers,dispersing

- Optional: platform, wheels, ladder,variable frequency drive,explosion-proof device

- Certificates: ASME, CE, GMP, UL, ATEX, ISO 9001

- Our equipment supports customisation, global delivery, and a 1-year warranty.

- If you have drawings, we can process them for you.

Note: Please contact our sales team before placing an order. Website prices are for reference only; specific pricing requires understanding your requirements to provide a quote.

Email:info@ace-chn.com

Tel: +86 186 2683 5909

WeChat: ace-chn

WhatsApp: +86 186 2683 5909

$3,666.00

Guaranteed Safe Checkout

Recommend RPM: 0-960RPM

Viscosity: Low/medium viscosity

Application: Mainly Liquid mixing

Recommend RPM: 0-200RPM

Viscosity: Low/medium viscosity

Application: Mainly Liquid mixing

Recommend RPM: 30RPM

Viscosity: Medium/High viscosity

Application: Melting, High viscosity product mixing, For single wall tank

Recommend RPM: 30RPM

Viscosity: Medium/High viscosity

Application: Melting, High viscosity product mixing, For jacket tank

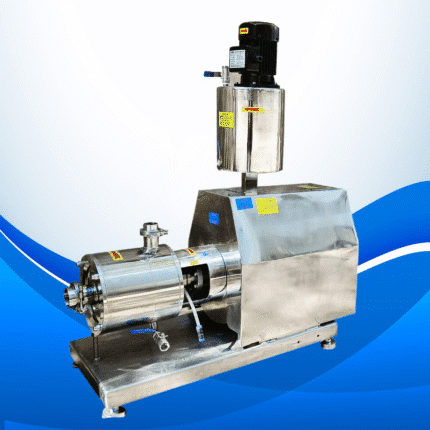

Recommend RPM: 1480/2850 RPM

Viscosity: Low/medium viscosity

Application: Liquid powder mixing and dispersion

Recommend RPM: 1480/2850 RPM

Viscosity: Low/medium/High viscosity

Application: Liquid powder mixing and homogenizing

Recommend RPM: 0-355RPM

Viscosity: Low/medium viscosity

Application: Install at bottom, No mechanical seal working condition

Recommend RPM: As above

Viscosity: Low/medium viscosity

Application: Liquid powder mixing and dispersion For tank volume >300L

Heated Mixing Tank Product Description

When you need to keep every drop at the right temperature while you mix, a heated mixing tank has your back. Built to pump steady heat through the blend, these tanks are tough, flexible, and ready to perform day in and day out. Whether you work in food production, drug manufacturing, or chemicals, our heated mixing tanks deliver the steady and speedy mixing you count on.

Why Choose Our Heated Mixing Tanks?

Precise Temperature Control

Each tank is sketched to keep a constant heat all the way through your mixing run. That’s vital any time chemical reactions, thinning liquids, or a smooth final product hinge on one heat setting. With top-range controls built in, our tanks lock in the perfect temp so you spend less time tweaking and more time producing.

Customizable Power and Voltage Options

Because no two workplaces share the same power feed, we give you plenty of ways to match your setup. Pick from:

- Voltage levels between 110V and 600V, so the tank plugs right into your system.

- Any of several power bands, from 1.5KW up to 55KW, letting you size the heater to the load.

Built Tough with Top-Quality Materials

When tanks sit in places that splash acid, steam, or heat on them all day, only real toughness will do. That’s why we make our heated mixers from 316L or 304 stainless steel: both resist rust, stay strong under stress, and wipe clean without a headache.

- 316L Stainless Steel: Great for lines that handle harsh chemicals or heavy corrosion, like pharma plants and food factories.

- 304 Stainless Steel: Easier on the budget and still perfect for most everyday jobs.

Mixing Power You Can Count On

No matter whether you pour in thin liquids, thick pastes, or dry powders, our tanks keep everything moving, so lumps don’t hide. Custom agitators sweep the entire volume, spreading heat as they blend and cutting mix time way down.

Any Job, Any Industry

Because they can heat and mix at the same time, our tanks fit a wide range of jobs:

- Food Processing: Heat and stir sauces, dairy mixes, or candy fillings.

- Pharma: Blend active compounds into steady solutions for pills or creams.

- Chemicals: Control heat while combining raw materials for exact reactions.

- Cosmetics: Whip up smooth lotions, creams, and gels that never separate.

Example Application

In candy factories, heated mixing tanks keep chocolate at the same warm temp while ingredients swirl, so every batch is silky and looks the same. In drug-making plants, a hot mixer holds the exact heat needed to combine oils and active powders, turning them into smooth creams or ointments.

Energy Efficient & Cost Effective

Built-in, power-smart heaters cut electricity waste, keeping your monthly bill lower while still giving top performance on every shift. An adjustable power setting lets you match the tank’s heat to what the job really needs, so the whole line runs greener and trims waste.

Specifications & Options

| Feature | Description |

|---|---|

| Voltage | 110V, 220V, 380V, and 600V available. Other voltages on request. |

| Power Options | 1.5 kW, 5 kW, 10 kW, 20 kW, 30 kW, or 55 kW output. |

| Material | Choose 316L or 304 grade stainless steel shell. |

| Agitator Types | Paddle, anchor, or stirrer blades to match your mix. |

| Temperature Control | The built-in digital readout keeps heat on target. |

| Heating Method | Pick electric coils or steam feed for heating. |

Order Today and Personalize Your Tank

Every project has its own story, and so does every mixing tank. We let you shape features like size, power, and finish, so it fits your process perfectly. Chat with our team, straighten out the details, and request a free quote-no obligation at all!

Frequently Asked Questions

Who needs to be heated mixing tanks?

Food plants, drugmakers, cosmetic shops, and chemical firms all rely on them whenever they must blend at a set temperature.

Can I get a one-of-a-kind size?

Absolutely. Tanks range from handy lab units to big factory kettles, and we can fine-tune volume and layout for your space.

How long does it take for the tank to heat up?

How long it takes really depends on the tank size, heater wattage, and heating method you choose. Our heaters are engineered to warm the tank quickly, so you spend less time waiting and more time working.

What maintenance is required for a heated mixing tank?

Keeping your tank in shape is simple-clean the walls and paddles, look at the heating coils, and test the temp controls every few months. A quick check like this will help the unit run longer and keep production steady.

Can I use this tank for both heating and mixing at the same time?

For sure! Our heated mixing tanks let you heat and mix at the same time, so everything sits at the right temp without hot or cold spots.

Why wait? Make the smart investment in a heated mixing tank today!

If you want reliable, efficient, and tough equipment, our heated mixing tanks deliver. Customize yours to fit your shop, then call or email and well get your order moving, so you can boost production without delay.