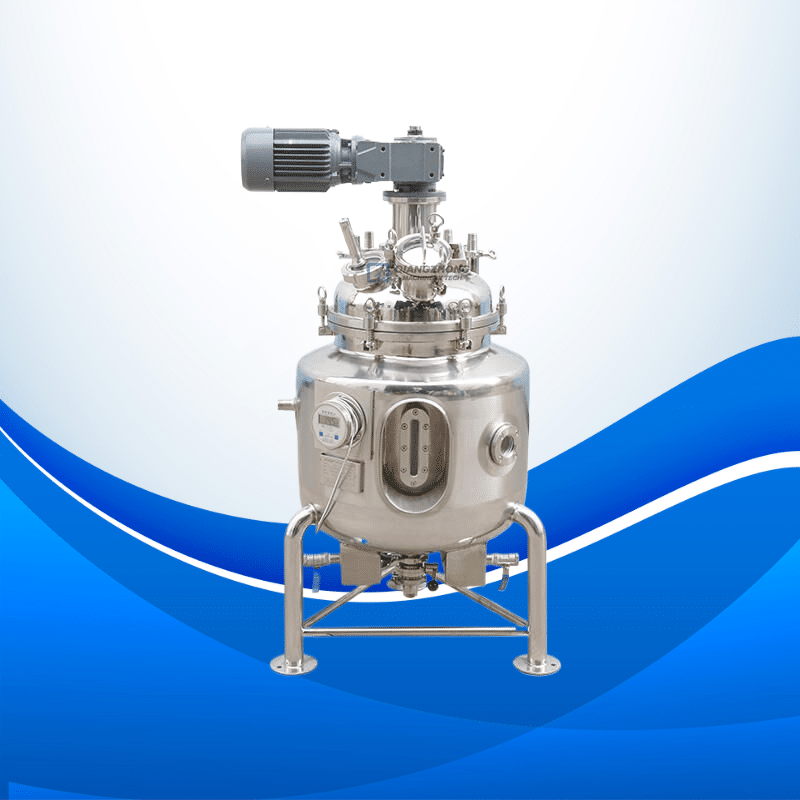

Fertilizer Mixing Tank: The Best Tool for Quick, Even Mixing

Today, getting fertilizers mixed exactly right makes a big difference on the farm. Whether you run a big field, a busy greenhouse, or a facility that makes blends, a good mixing tank keeps every batch the same. With a tough build and smart add-on features, our tanks give you the reliability you need day after day.

Why Growers Trust Our Mixing Tanks

Power and Voltages Made for You

Each tank is offered with a wide choice of motors and power setups, so everything fits the way you work. Pick between 1.5KW and 55KW and choose from 110V all the way up to 600V, letting you match the mixer’s load and your site’s volt limit. No matter if the operation is small or massive, this kind of freedom helps keep every batch moving, on time, with no fuss.

Superior Mixing Efficiency

These tanks use modern mixing tech that blends fertilizers super evenly, so nothing gets lumpy or out of whack. That matters on the farm, because crops need the same nutrient balance all through the season to grow their best. Powerful agitators spin through tough mixes—whether they’re powders, liquids, or pellets—and keep everything moving until it’s homogenous.

Durability with High-Quality Materials

Built for heavy use, each tank come to your choice of rugged grade-316L stainless steel or 304 stainless steel. The 316L version fights corrosion like a champion, so it’s perfect for harsh fertilizers that chew up weaker metals. The 304 still offers solid toughness for everyday blends, and both styles clean up quickly, stopping any leftover product from tagging along into the next batch.

Adaptability for Multiple Applications

These mixing tanks settle into all kinds of settings—agriculture, horticulture, even small chemical shops—and get the job done. They handle granular or liquid fertilizers, nutrient soups, and can even whip up a batch of compost. Organic or synthetic, the careful blending they provide translates to higher product quality and stronger, healthier plants once the mix hits the field.

Safety and Ease of Operation

Every tank comes with tightly-fitting lids, an anti-overflow valve, and a quick shut-off switch you can reach in seconds. The push-button controls light up in clear English, so even new staff can start mixing within minutes. Together, these features stop spills and keep the process safe from loading to clean-up.

Common Applications and Scenarios

Large-Scale Agricultural Operations

Big farms order fertilizer by the truckload, so they need heavy-duty gear that never slows them down. The mixing tank gobbles up those big batches, stirring everything fast and steady, and delivers a blend that spreads evenly over miles of rows.

Greenhouses and Nurseries

Inside glasshouses and small nurseries, plants often demand special recipes delivered on schedule, and the tank steps in perfectly. It measures each ingredient with pinpoint accuracy, giving roots the exact feed they need for strong growth and thick blossoms.

Fertilizer Manufacturing Facilities

Commercial plants that make fertilizer for retail shelves count on these tanks to turn powders and granules into ready-to-use bags. With a roomy drum and fast mixer, each cycle winds up with the same quality from the first scoop to the last, keeping customers happy.

Custom Fertilizer Production for Specific Crops

When a farm grows specialty crops, off-the-shelf fertilizer often misses the mark. Our mixing tanks let you blend nutrients exactly how each field or greenhouse needs them.

Fertilizer Mixing Tank Parameters

- Voltage Options: 110V, 220V, 380V, 600V (we can build to other voltages, too).

- Power Range: 1.5KW to 55KW.

- Material Options: Pick 316L Stainless Steel if your formula is corrosive, or stick with 304 for most jobs.

- Mixing Capacity: Any size that matches your workflow.

- Agitator Design: Set up for liquids, granules, or powders.

- Control System: Easy-to-read touch screen with program presets and live monitoring.

Why Choose Our Fertilizer Mixing Tanks?

- High Customizability: Match power, voltage, material, and tank size to your needs.

- Reliable Performance: Rugged build stays consistent job after job.

- Easy Maintenance: Slick design makes cleaning quick, cuts downtime.

- Comprehensive Customer Support: We help from setup through repairs, so you never work alone.

Order Your Fertilizer Mixing Tank Today!

Ready to upgrade the way you mix fertilizer? Our tanks are tough, efficient, and built to give you smooth, even blends every time. Whether you work on a farm, in a factory, or in any other field that needs spot-on mixing, we have a model sized just for you.

If your setup has special needs, we can tweak the design to match them. Reach out now for a quick quote or to lock in your order. Our friendly team will make sure you walk away with the right tank.

Frequently Asked Questions (FAQs)

1. What size fertilizer mixing tank should I choose?

Pick a tank based on how much fertilizer you want to mix at once and how big your operation is. With models ranging from small tubs to large silos, our crew can suggest the one that suits you best.

2. Can the fertilizer mixing tank handle both liquid and granular fertilizers?

Absolutely! Each tank beater can mix liquids, granules, or even fine powder, and the blades can be tuned to match whatever material you use.

3. Is the tank easy to clean?

Absolutely, the tanks are set up for quick cleaning and regular upkeep. Because we use smooth 304 and 316L stainless steel, gunk doesn’t stick as easily, and a simple wipe or rinse usually does the trick.

4. What voltage options do you offer?

We offer a range of voltages from 110V all the way up to 600V, so you can pick the level that matches the power supply at your site.

5. Can I customize the agitator design?

For sure—we can tweak the agitator to suit the kind of material you are mixing. Our engineers will team up with you to make sure the new design gives the best mixing performance for your job.