Product Description:

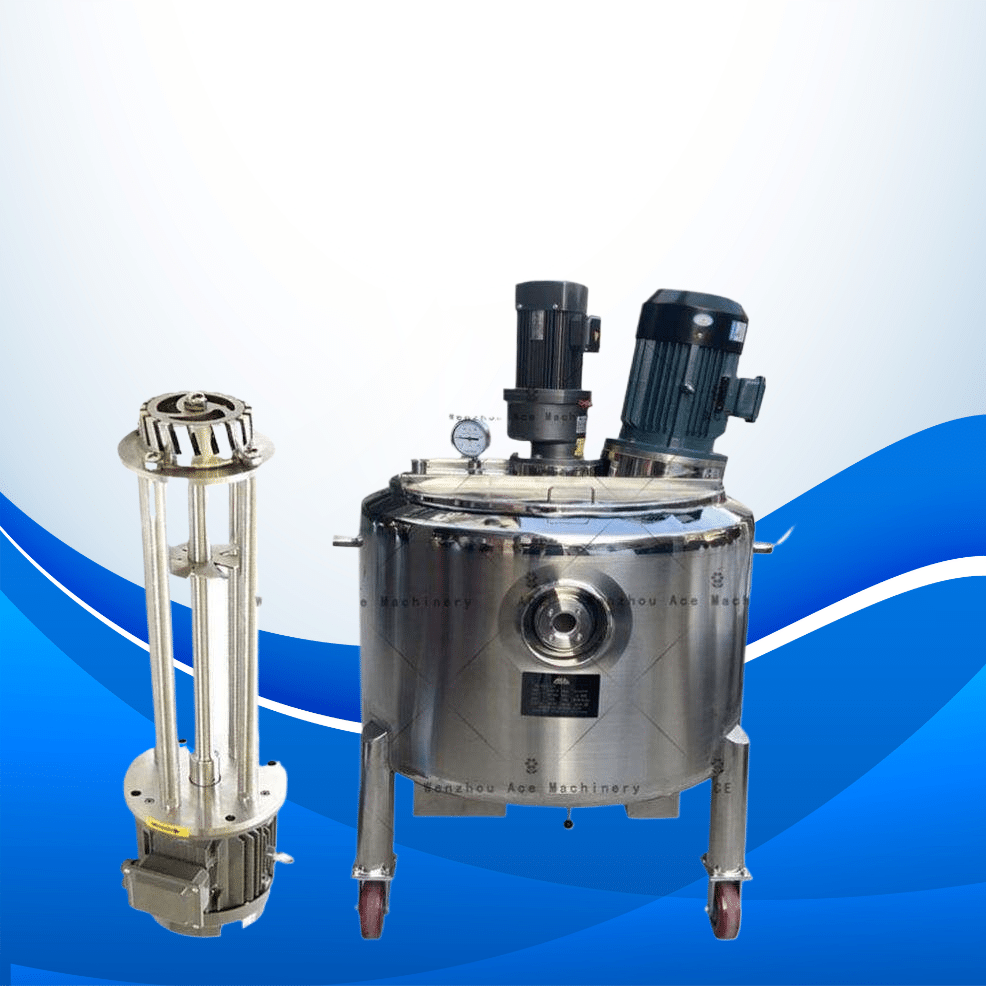

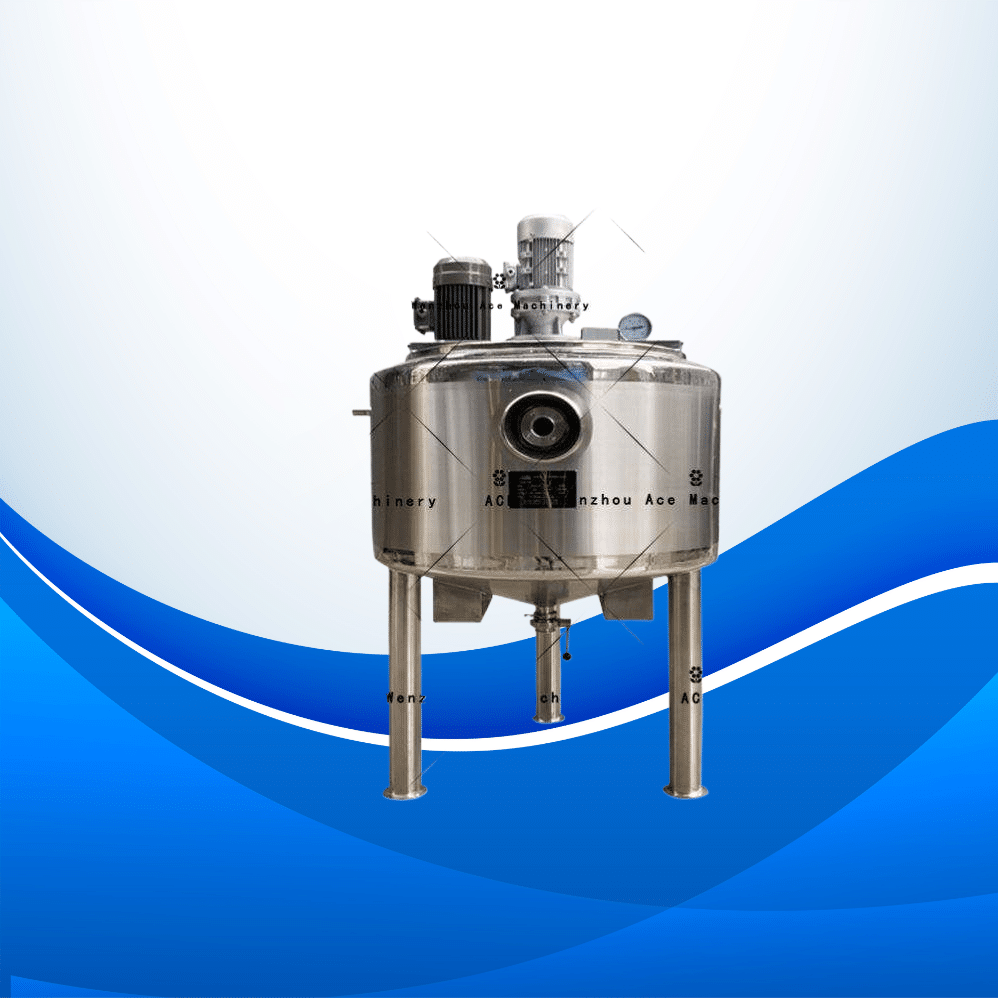

100 Gallon Stainless Steel Mixing Tank-Efficiency, Durability, and Customization for Your Industrial Needs

When mixing large batches in a busy factory, you need more than just a big drum. The 100-gallon stainless steel mixing tank gives you the steady, high-performance partner you want. Food plants, drug manufacturers, beauty-product makers, and even chemical lines count on this tough tank to keep every batch uniform. Built solid and packed with options, it keeps work flowing and fits into your long-term budget.

Key Features and Advantages:

Premium Stainless Steel Construction:

Crafted from food-grade 316L or cost-effective 304 stainless steel, this tank shrugs off rust, stains, and harsh cleaners so it stays bright for years. Whether you fill it with sugary syrup, lotion, or corrosive powder, the material takes the punishment while keeping the inside spotless.

Generous 100-Gallon Capacity:

With room for 100 gallons, the tank handles everything from test runs to mid-size orders without a hitch. That sweet spot between small-jumbo lets you run quick changes yet still pump out enough volume to keep lines moving.

Custom Power and Voltage Choices:

This mixing tank can be set up with the power and voltage you actually need. It comes in sizes from 1.5 kW all the way up to 55 kW, and you can pick a supply between 110 V and 600 V. That means you get a low-power model for gentle tasks or a beefy version for heavy mixing, so almost any plant electrical draw works with it.

Flexible, Reliable Mixing:

Thanks to smart mixer design, the tank blends liquids, powders, even thick pastes quickly and evenly. Whether you are folding ingredients, making creams, or melting solids into a solution, the 100-gallon stainless-steel drum gives steady results and cuts down on cycle time. Fewer do-overs mean more production, plain and simple.

Simple to clean, Safe to Use:

Its polished stainless surface wipes clean in minutes, which matters when every drop counts. Fast cleanup meets strict hygiene rules in food, cosmetics, and pharma lines, helping you stay on schedule while keeping regulators happy. Less downtime for sanitizing also protects batch quality and keeps employees safe.

Safety Features and Durability

Every mixing tank is built with safety in mind, and this model is no exception. Pressure-release valves open when things get too tense, heavy-duty supports keep the body steady, and extra-strong welds fight off metal fatigue. All these features team up to let the tank shrug off both internal pressure and the bumps that come with daily use.

Application Scenarios

With 100 gallons of mixing room, the stainless steel tank stars in plenty of different workspaces. Here are a few places you might spot it on the job.

Food and Beverage Industry

Factories use it for mixing big batches of sauces, soups, juices, and dressings. Smooth surfaces make clean-up quick, so the tank still meets the toughest food-safety rules after every run.

Pharmaceutical Production

Medicine makers need accuracy and 100% cleanliness, and this tank helps deliver both. Its sanitary finish ticks the GMP box, and optional voltage settings let operators match power to local grids.

Cosmetics Manufacturing

Lotion, cream, and shampoo lines rely on it to blend oils, water, and actives without lumps. When ordered in 316L steel, the tank stays neutral, keeping formulas free of unwanted metal traces.

Chemical and Industrial Mixing

Our 100-gallon mixing tank is built for tough jobs like blending coatings, making adhesives, and other factory tasks, and it takes whatever recipe you feed it. You pick the power level and voltage, so whether you need gentle stirring or a full-on whirl, the tank does the work.

Customization Options & Specifications:

- Capacity: 100 gallons

- Material: Choose 316L for extra corrosion resistance or 304 for standard stainless-steel strength.

- Voltage: 110 V, 220 V, 380 V, or 600 V.

- Power: 1.5 kW to 55 kW.

- Mixer Type: Pick a top-entry, side-entry, or bottom-entry system to match your workspace.

Optional Features:

- Heating-and-cooling jacket keeps liquids at the right temperature.

- Speed-control lets you dial in the exact stir rate.

- Custom inlets and outlets speed up loading and emptying.

- Pressure-relief valves protect workers and equipment.

- Integrated filters or strainers catch clumps before the next step.

Why Choose Our 100-Gallon Stainless Steel Mixing Tank?

Durability:

Built with heavy-duty welds and thick walls, the tank survives day-to-day use, even when operated non-stop.

Flexibility:

Every plant is a little different. Our menu of options means you get a system that fits your process, not the other way around.

Simple Care:

Color-coded controls and smooth internal surfaces cut cleaning time and make training new staff quick, so you save hours and money.

Cost-Effective Performance:

Thanks to energy-saving motors and very little downtime, our mixing tank pays for itself over time. Fewer bills and more output? That feels like a win-win.

Call to Action:

Stop waiting for the next upgrade. If you need a rugged, 100-gallon mixing tank that flexes, lasts, and works hard, contact us for a quick quote or to talk about piece-by-piece changes. Our people will make sure you get the setup your operation demands.

Frequently Asked Questions (FAQ):

What is the difference between the 316L and 304 stainless steel options?

316L fights rust better and shines in food, drug, or chemical lines where things can get rough. 304 is the everyday steel that handles most standard jobs.

Can I customize the voltage and power of the mixing tank?

Absolutely; it can run on anything from 110V, 1.5KW up to 600V, 55KW, so you get the juice your shop already uses.

Is the tank easy to maintain?

Yes, stainless steel wipes clean in a flash, so it meets the hygiene rules and your own sanity in busy plants.

What industries work well with this mixing tank?

This mixing tank shines in kitchens, drug labs, makeup factories, chemical plants, and plenty of other places. Because it adapts easily, it handles almost any stirring or blending job you throw at it.

How long does it take to get the tank after I order?

Lead time really hinges on the extras you pick and how our stock looks at the moment. Under normal circumstances, you can plan on seeing it at your door in roughly 4 to 6 weeks.

Can I order a tank built to my exact size?

Absolutely! We’re happy to craft a tank that matches your space and process. Just reach out, and we’ll walk you through the details together.