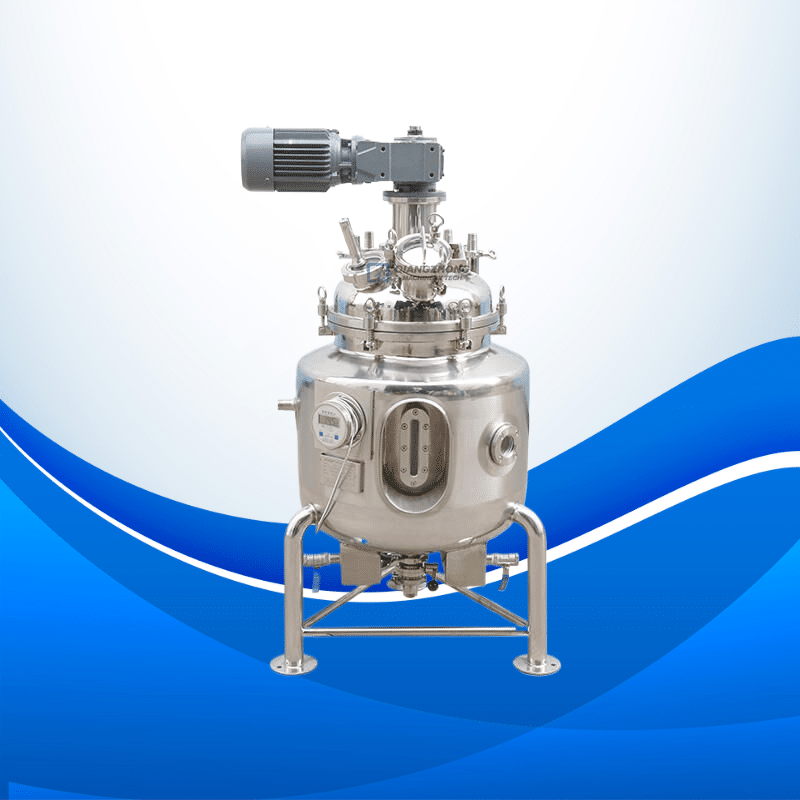

High-Quality Stainless Mixing Tanks

- Capacity: 50 liters to 30,000 liters

- Mixer power: 1.5 kW to 55 kW

- Material: 304 or 316L

- Voltage: 110V to 600V

- Heating method: Electric or steam heating

- Layer:single/double jacket/three jacket

- Mixer types: Impeller-type, Anchor-type, Turbine-type, High-shear-type, Magnetic mixer, Anchor-type mixer with scrapers,dispersing

- Optional: platform, wheels, ladder,variable frequency drive,explosion-proof device

- Certificates: ASME, CE, GMP, UL, ATEX, ISO 9001

- Our equipment supports customisation, global delivery, and a 1-year warranty.

- If you have drawings, we can process them for you.

Note: Please contact our sales team before placing an order. Website prices are for reference only; specific pricing requires understanding your requirements to provide a quote.

Email:info@ace-chn.com

Tel: +86 186 2683 5909

WeChat: ace-chn

WhatsApp: +86 186 2683 5909

$3,900.00

Guaranteed Safe Checkout

Recommend RPM: 0-960RPM

Viscosity: Low/medium viscosity

Application: Mainly Liquid mixing

Recommend RPM: 0-200RPM

Viscosity: Low/medium viscosity

Application: Mainly Liquid mixing

Recommend RPM: 30RPM

Viscosity: Medium/High viscosity

Application: Melting, High viscosity product mixing, For single wall tank

Recommend RPM: 30RPM

Viscosity: Medium/High viscosity

Application: Melting, High viscosity product mixing, For jacket tank

Recommend RPM: 1480/2850 RPM

Viscosity: Low/medium viscosity

Application: Liquid powder mixing and dispersion

Recommend RPM: 1480/2850 RPM

Viscosity: Low/medium/High viscosity

Application: Liquid powder mixing and homogenizing

Recommend RPM: 0-355RPM

Viscosity: Low/medium viscosity

Application: Install at bottom, No mechanical seal working condition

Recommend RPM: As above

Viscosity: Low/medium viscosity

Application: Liquid powder mixing and dispersion For tank volume >300L

Product Description: Stainless Mixing Tank

Whether you are whipping up a batch of sauce, blending medicines, or stirring Dutch cocoa powder into batter, a stainless mixing tank makes the job smoother and faster. Built for everyday use in food plants, pharmacies, chemical labs, and beauty-product lines, our tanks marry precise design with knock-around durability, so they keep running quietly day after day.

Key Features and Advantages:

Durability and Corrosion Resistance:

Crafted from top-grade stainless steel, the drum laughs in the face of moisture, rust, and most aggressive cleaners a factory might pour on. With two sheet options-316L for salty, acidic loads, and 304 for every day tasks-the tank lasts through wash downs and heavy batches alike, shielding your process, and your budget, from unplanned replacement costs.

Customizable Power and Voltage Options:

One mixing job can sit at 1.5 kilowatts while another needs 55, so we give you that choice straight out of the box. Pair each amperage with the voltage your plant uses, from 110-volt outlets in a test kitchen up to 600-volt grids found in export factories, and plug in without extra adapters.

Precision Mixing Technology:

Our mixing tanks blend like a pro, turning thick liquids, pastes, or creamy emulsions into a steady stream without lumps. Purpose-built agitators sweep the whole batch, while adjustable speeds let you crank up or dial down the action on the fly.

Sanitary Design for Easy Cleaning:

Stainless-steel walls shine with a polished finish that keeps hidden corners to a minimum, so cleaning takes less time and the risk of stray germs stays low. Thoughtful angles also cut out dead spots where material might sit and spoil, letting you run a safe line with less worry.

Applications and Use Cases:

These stainless mugs fit almost any job, and people across different industries keep finding new ways to use them. Check a few classic examples below.

Food and Beverage Industry:

Whether you’re folding bakery batter, whisking dressings, or blending sauces and soups, the tanks lay down an even texture and true taste every time. For recipes that hit with acid, the 316L grade stands guard, resisting rust while meeting the strict hygiene rules of the food world.

Pharmaceutical Manufacturing:

When you’re making medicines, ointments, or syrups, our stainless mixing tanks keep every batch blended the same from start to finish. Their clean design and accurate stirring are exactly what you need in pharma, where even tiny recipe changes matter a lot.

Cosmetic Production:

Mixing lotions, creams, or any other beauty product is easier when the tank’s smooth walls cut the risk of bits and pieces sneaking in. You can also pick from different sizes and steel grades so the gear matches the strict rules your shop has to follow.

Chemical Industry:

In the chemicals world, these stainless tanks are workhorses, handling gentle liquids right through to stuff that eats regular metal for breakfast. Heavy-duty build and leak-free seals mean the system keeps running safely even when the temperature or pressure goes off the charts.

Technical Specifications:

- Capacity: We can make any size you need, from small pilot models to big factory units.

- Materials: Pick either 304 or 316L stainless steel; 316L shines in salty, super-hot tank rooms, while 304 does the job well when conditions are normal and budget is tight.

- Voltage: Tanks come wired for anything from 110V home power to 600V industrial grids, so they just plug into the setup you already have.

- Power: Motors run from happy 1.5KW testers right up to hefty 55KW beasts, letting you scale horsepower to the size of your job and how tricky the mix is.

- Agitator Type: Pick an anchor, turbine, or paddle type so it suits the material you mix.

- Other Features: Add heating, cooling, or a jacketed wall if the mix needs special temperature care.

Why Choose Our Stainless Mixing Tanks?

- Customization: Need a certain size, steel grade, or motor power? We build it your way.

- Robust Construction: Heavy-duty design keeps the tank working nonstop in any industry.

- Easy Maintenance: Smooth surfaces and clear fittings make cleaning quick and cut downtime.

- Industry-Specific Solutions: Our tanks meet strict rules for food, pharma, cosmetic, and chemical work.

Order Your Stainless Mixing Tank Today

Ready for a dependable, high-performance tank that fits your process? Whether you’re replacing old gear or launching new lines, our stainless steel vessels deliver the quality you expect. With full customization, we help your operation run smoothly.

Give us a shout today to go over what you need, ask for a quote, or place your order. Upgrading to a high-grade stainless mixing tank could boost your process, so don’t let this chance slip by!

Common Questions (FAQ):

What material should I pick for my stainless mixing tank: 304 or 316L?

Pick 316L for very corrosive liquids or when you need extra toughness; 304 works well for regular jobs and keeps your budget in check.

Can I order a tank in a specific size?

Absolutely! Just tell us the volume and the outside measurements you want, and we’ll build it to fit your line.

How do I pick the right power and voltage for my tank?

We offer tanks from 1.5KW to 55KW and voltages between 110V and 600V. Share your setup with us, and we’ll guide you to the best match.

Can you add extras like heating or cooling?

For temperature-sensitive recipes, we can install jackets that heat or chill the liquid. Just say what you need, and we’ll make those features part of the design.