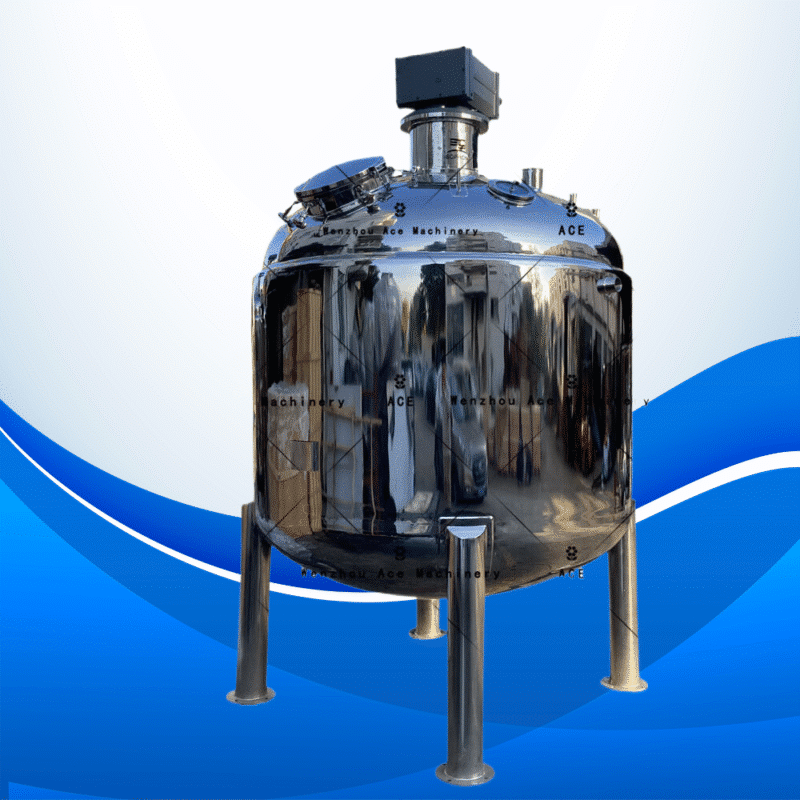

Premium Batch Mixing Tank Solutions for Industrial-Grade Liquid Blending

- Capacity: 50 liters to 30,000 liters

- Mixer power: 1.5 kW to 55 kW

- Material: 304 or 316L

- Voltage: 110V to 600V

- Heating method: Electric or steam heating

- Layer:single/double jacket/three jacket

- Mixer types: Impeller-type, Anchor-type, Turbine-type, High-shear-type, Magnetic mixer, Anchor-type mixer with scrapers,dispersing

- Optional: platform, wheels, ladder,variable frequency drive,explosion-proof device

- Certificates: ASME, CE, GMP, UL, ATEX, ISO 9001

- Our equipment supports customisation, global delivery, and a 1-year warranty.

- If you have drawings, we can process them for you.

Note: Please contact our sales team before placing an order. Website prices are for reference only; specific pricing requires understanding your requirements to provide a quote.

Email:info@ace-chn.com

Tel: +86 186 2683 5909

WeChat: ace-chn

WhatsApp: +86 186 2683 5909

$3,790.00

Guaranteed Safe Checkout

Recommend RPM: 0-960RPM

Viscosity: Low/medium viscosity

Application: Mainly Liquid mixing

Recommend RPM: 0-200RPM

Viscosity: Low/medium viscosity

Application: Mainly Liquid mixing

Recommend RPM: 30RPM

Viscosity: Medium/High viscosity

Application: Melting, High viscosity product mixing, For single wall tank

Recommend RPM: 30RPM

Viscosity: Medium/High viscosity

Application: Melting, High viscosity product mixing, For jacket tank

Recommend RPM: 1480/2850 RPM

Viscosity: Low/medium viscosity

Application: Liquid powder mixing and dispersion

Recommend RPM: 1480/2850 RPM

Viscosity: Low/medium/High viscosity

Application: Liquid powder mixing and homogenizing

Recommend RPM: 0-355RPM

Viscosity: Low/medium viscosity

Application: Install at bottom, No mechanical seal working condition

Recommend RPM: As above

Viscosity: Low/medium viscosity

Application: Liquid powder mixing and dispersion For tank volume >300L

Premium Batch Mixing Tank for Efficient Industrial Blending

Introduction: Precision Mixing for Modern Industry

Modern factory floors buzz with activity, and no one can afford delays caused by inconsistent mixing. Our batch mixing tank delivers the controlled blending that industries like food and drink, pharma, cosmetics, and chemicals rely on when quality and speed matter. Because every load is weighed, heated, and stirred in an enclosed environment, operators get the same texture or active level order after order. The tank can even handle formulas that are thick, sensitive to shear, or easy to settle out.

Engineered for performance, the unit-size motor, 316L internals, and a double-jacket wall adapt to whatever recipe you run—easy hand is kept on routine secondary work. This guide highlights customer stories, technical benefits, optional extras like mobile stands or PLCs, and explains why investing in robust, repeatable technology now saves money later.

Key Features and Specifications

Attention to materials and assembly extends equipment lifespan while keeping maintenance chores predictable. Standard features include:

Power Range: 1.5 kW to 55 kW

Pick the motor that matches your volumes and viscosities, whether you need slow folding or aggressive high-torque shear.

Voltage Options: 110 V to 600 V

Worldwide electrical standards.

Finish: Food-safe bead blasted or electro-polished

Minimizes contamination risk and eases clean-in-place routines.

Working Volume: 100 L to 10,000 L

Small pilot units verify tests before plant-scale production.

Drive: Direct-coupled gearbox with dynamic overload protection

Promotes quieter operation and prevents damage from sudden stalls.

Material Choices: 304 stainless steel for everyday jobs or top-grade 316L for the toughest uses.

316L is the go-to when cleanliness really matters, like in food and pharma lines, because it fights rust even better.

Tank Volume

We build tanks from 100 liters for pilot tests all the way up to 10,000 liters or more. That makes them handy whether you’re still in the lab phase, running a middle-size batch, or running full factory loads.

Agitation Type

Pick a top-mount mixer or a side-mount one; each comes with blades made for what you’re blending.

Control Panel

Add a PLC that shows temp and RPM right on the screen, or keep it simple with manual dials.

With this mix of choices, every tank becomes more than a drum; it turns into a complete, ready-to-run blending station.

Real-World Applications and Use Scenarios

Whenever you need to blend liquids or thick pastes just right, a batch mixing tank is the piece of gear you reach for. Here are some spots you’ll find them.

Food and Beverage

Whether you’re making barbecue sauce, yogurt, or energy drink mix, these tanks do the job. The smooth 316L walls pass every safety check.

Pharmaceutical Production

They mix powders, syrups, and injectable solutions under the watch of strict rules. When a PLC runs the show, every blend is a twin of the last one.

Cosmetics and Personal Care

Lotions, shampoo, and facial serums come out silky, with no lumps. Adjustable speed lets formulators fine-tune the mix until feel and spread are perfect.

Chemical Manufacturing

Resins, polymers, acids, and solvents are no problem. Special liners and gaskets guard against aggressive recipes, so things stay leak-free and safe.

In every situation where our tanks go online, customers see: the difference between one batch and the next shrinks, cooks finish sooner, machines do more of the heavy lifting, and the whole system stays tight and clean thanks to welded 316-L stainless.

Picture your line with our tank plugged in—it’s easy to see more product leaves the floor, defects drop, and supervisors get a steadier read on what’s happening.

Why Pick Our Batch Mixing Tank?

Here are the reasons many customers choose our gear:

Tailored Design

Each tank is engineered around your recipe and floor layout, so you get exactly what you need.

Worldwide Voltage Options

We deliver for every socket—from 110 volts in Texas to 400 volts in Berlin and even rugged 600-volt plants.

Top-Grade Materials

316-L stainless stands up to citric acids, salts, and repeated washdowns. It’s the go-to grade where hygiene matters most.

Smart Power Use

Motors range from 1.5 kilowatts in small labs to 55 kilowatts in high-volume lines, letting you save energy without trading speed.

Fast Clean-Up

CIP-Ready internals mean crews spend minutes, not hours, getting the tank ready for the next run.

Ongoing Expertise

Our engineers stay in touch after start-up, helping troubleshoot or upgrade so your equipment stays profitable.

From kitchen startups to multinational plants, customers count on our tanks to increase volume while keeping batches safe and consistent.

Call to Action: Get a Custom Quote Today

Thinking about upgrading your mixing operations? Our team is ready to design a batch mixing tank that fits your specific industry requirements. With a wide range of tweaks and direct technical support, we promise a setup that smooths out your workflow.

Reach out for a no-cost consultation and quick quote. We also offer bulk savings and rush production schedules. Whether you want one standalone tank or a complete system, our industrial-grade equipment gets the job done.

Frequently Asked Questions

Q: What size batch mixing tank should I choose?

A: Your ideal size depends on the volume and thickness of what you’ll be mixing. We stock models from 100 liters right up to more than 10,000 liters.

Q: Can I use this tank for high-viscosity materials?

A: Definitely. Pairing a heavy-duty motor-up to 55 kilowatts-with a custom impeller makes light work of even the thickest mixes.

Q: What’s the difference between 304 and 316L stainless steel?

A: While 304 is tough, 316L stands up to corrosion better and is the go-to for sensitive or acidic recipes.

Q: Is the system compatible with automation?

A: Of course. Each tank can be made PLC-ready and fitted with data logging, temperature control, and automated batching.

Q: How fast can I get a custom tank?

A: The build time depends on what you order, but the usual wait is around 2 to 4 weeks. We can speed things up if you need a rush job.