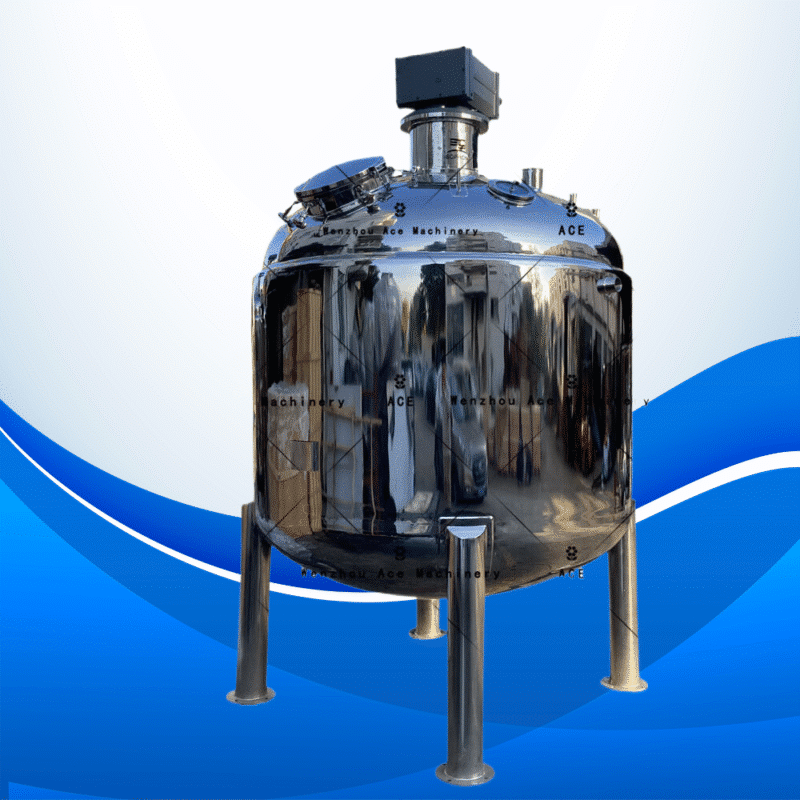

1000L Jacketed Mixing Tank

- Capacity: 50 liters to 30,000 liters

- Mixer power: 1.5 kW to 55 kW

- Material: 304 or 316L

- Voltage: 110V to 600V

- Heating method: Electric or steam heating

- Layer:single/double jacket/three jacket

- Mixer types: Impeller-type, Anchor-type, Turbine-type, High-shear-type, Magnetic mixer, Anchor-type mixer with scrapers,dispersing

- Optional: platform, wheels, ladder,variable frequency drive,explosion-proof device

- Certificates: ASME, CE, GMP, UL, ATEX, ISO 9001

- Our equipment supports customisation, global delivery, and a 1-year warranty.

- If you have drawings, we can process them for you.

Note: Please contact our sales team before placing an order. Website prices are for reference only; specific pricing requires understanding your requirements to provide a quote.

Email:info@ace-chn.com

Tel: +86 186 2683 5909

WeChat: ace-chn

WhatsApp: +86 186 2683 5909

$5,100.00

Guaranteed Safe Checkout

Recommend RPM: 0-960RPM

Viscosity: Low/medium viscosity

Application: Mainly Liquid mixing

Recommend RPM: 0-200RPM

Viscosity: Low/medium viscosity

Application: Mainly Liquid mixing

Recommend RPM: 30RPM

Viscosity: Medium/High viscosity

Application: Melting, High viscosity product mixing, For single wall tank

Recommend RPM: 30RPM

Viscosity: Medium/High viscosity

Application: Melting, High viscosity product mixing, For jacket tank

Recommend RPM: 1480/2850 RPM

Viscosity: Low/medium viscosity

Application: Liquid powder mixing and dispersion

Recommend RPM: 1480/2850 RPM

Viscosity: Low/medium/High viscosity

Application: Liquid powder mixing and homogenizing

Recommend RPM: 0-355RPM

Viscosity: Low/medium viscosity

Application: Install at bottom, No mechanical seal working condition

Recommend RPM: As above

Viscosity: Low/medium viscosity

Application: Liquid powder mixing and dispersion For tank volume >300L

Product Description: Jacketed Mixing Tank

A jacketed mixing tank is a workhorse for any plant that needs to keep its liquids at just the right temp while stirring them well. From sauces in the food aisle to creams in the drugstore, these double-walled vessels let you heat up or cool down the mix at the same time that your blades are turning. With options for different power levels, materials, and voltages, each unit can be fine-tuned to the way you run your line.

Key Features and Benefits

Gentle Heat or Chill

The jacketed walls hold a not-too-hot or not-too-cold fluid, so sensitive mixtures-emulsions or sugar crystals, for instance-never grab or crash.

Strong Agitation

Heavy-duty paddles or turbine mixers rip through low or high viscosities, turning quick liquids, thick pastes, and everything in between into a single, smooth batch.

Wide Industry Fit

Because the needs of every shop are unique, these tanks slide into almost any line.

In Pharmacies

They keep drug mixes within tight temp limits from start to finish.

In Food and Drink Plants

They pasteurize sauces, stir flavors, and blend powders without overshoot.

In Chemical Halls

They create seal-proof setups for polymer or pigment runs where every degree counts.

Cosmetics & Personal Care

Perfect for blending lotions, creams, and other beauty formulas while keeping the mix at the right warmth.

Customizable Power and Voltage Options

Our jacketed tanks come with wattage of 1.5KW to 55KW and voltage from 110V to 600V so you can match the power supply you have.

Durable Materials

Pick 316L stainless steel for super-corrosive liquids, or 304 stainless steel when the product is less demanding.

Technical Specifications:

Capacity

Made to order from 100 liters up to several thousand liters.

Material Options:

- 316L Stainless Steel: Best choice when corrosion is a big concern.

- 304 Stainless Steel: Works well for most jobs where corrosion is mild.

Voltage Options:

- 110V to 600V: Fits the main electrical standards around the world.

Power Options:

- 1.5KW to 55KW: Sized to your mixing speed and tank volume.

Mixing Speed

Can be changed to suit thick or thin liquids.

Application Scenarios:

Pharmaceutical Industry

When making syrups, ointments, or even vaccines, keeping the right temperature stops ingredients from breaking down and makes sure every batch is the same.

Food and Beverage

Whether you’re tempering chocolate, making sauces, or processing dairy, these tanks keep heating and cooling on the dot so every batch tastes and looks the same.

Chemical Manufacturing

When blending chemicals for paints, coatings, or adhesives, a jacketed mixer steadies the temperature so reactions happen the way they should, every single time.

Cosmetic Production

Creams, gels, and lotions come out smooth and stable only when the mix stays at the right heat; our tanks help the ingredients whip together instead of separating.

Why Choose Our Jacketed Mixing Tank:

Customizable to Your Needs

Pick a power rating between 1.5 KW and 55 KW, and choose from 110-V to 600-V, so the tank matches your workshop and your output.

Superior Material Quality

Go with 316 L if corrosion is a concern, or stick with 304 for most other jobs; either way the stainless steel shields your product and your plant.

Optimized for Efficiency

A tough agitator and a clever jacket work together to spread heat or chill evenly, cutting wasted energy and stopping hot or cold spots.

Durability and Reliability

Made from heavy-grade stainless steel and welded for strength, these tanks shrug off the bumps of everyday use and keep delivering year after year.

Full Support

From set-up through regular check-ups, our team is here to customize and keep your line running without a hitch.

Call to Action

Want to upgrade your mixing with a high-output jacketed tank? Reach out now, and we’ll build a solution just for you. We promise quick shipping, hands-on install help, and long-term care to keep things humming. You deserve the best—let us show you why our tanks are the smart choice.

FAQs:

Q1: What’s the real difference between 316L and 304 stainless steel for these tanks?

A1: 316L shrugs off rust better and shines in tough places, so you’ll find it in pharma labs and food lines. 304 is lighter on the budget and works fine in most everyday mixing jobs.

Q2: How do I pick the right power and voltage for my jacketed mixing tank?

A2: Match power to how much you plan to mix and the wiring you already have. We offer voltage options from 110V to 600V and 1.5kW to 55kW power r ups. Our pros are ready to point you to the best fit.

Q3: What’s the best way to keep my jacketed mixing tank in shape?

A3: Stick to a routine—clean the tank, look over the agitator, check the jacket for any leaks, and make sure the heating or cooling parts are working. If you want, we can also send a team to handle all this for you so your gear runs like new.

Q4: Can I order a jacketed mixing tank in a size that fits my setup?

A4: Absolutely! From compact lab models to big industrial units, we can design and build a tank that matches your production needs perfectly.

Ready to Order?

Reach out today to go over your wish list, ask for a quote, or place an order for a custom jacketed mixing tank that will boost your lin