Buy High-Quality Liquid Mixing Tanks

- Capacity: 50 liters to 30,000 liters

- Mixer power: 1.5 kW to 55 kW

- Material: 304 or 316L

- Voltage: 110V to 600V

- Heating method: Electric or steam heating

- Layer:single/double jacket/three jacket

- Mixer types: Impeller-type, Anchor-type, Turbine-type, High-shear-type, Magnetic mixer, Anchor-type mixer with scrapers,dispersing

- Optional: platform, wheels, ladder,variable frequency drive,explosion-proof device

- Certificates: ASME, CE, GMP, UL, ATEX, ISO 9001

- Our equipment supports customisation, global delivery, and a 1-year warranty.

- If you have drawings, we can process them for you.

Note: Please contact our sales team before placing an order. Website prices are for reference only; specific pricing requires understanding your requirements to provide a quote.

Email:info@ace-chn.com

Tel: +86 186 2683 5909

WeChat: ace-chn

WhatsApp: +86 186 2683 5909

$3,870.00

Guaranteed Safe Checkout

Recommend RPM: 0-960RPM

Viscosity: Low/medium viscosity

Application: Mainly Liquid mixing

Recommend RPM: 0-200RPM

Viscosity: Low/medium viscosity

Application: Mainly Liquid mixing

Recommend RPM: 30RPM

Viscosity: Medium/High viscosity

Application: Melting, High viscosity product mixing, For single wall tank

Recommend RPM: 30RPM

Viscosity: Medium/High viscosity

Application: Melting, High viscosity product mixing, For jacket tank

Recommend RPM: 1480/2850 RPM

Viscosity: Low/medium viscosity

Application: Liquid powder mixing and dispersion

Recommend RPM: 1480/2850 RPM

Viscosity: Low/medium/High viscosity

Application: Liquid powder mixing and homogenizing

Recommend RPM: 0-355RPM

Viscosity: Low/medium viscosity

Application: Install at bottom, No mechanical seal working condition

Recommend RPM: As above

Viscosity: Low/medium viscosity

Application: Liquid powder mixing and dispersion For tank volume >300L

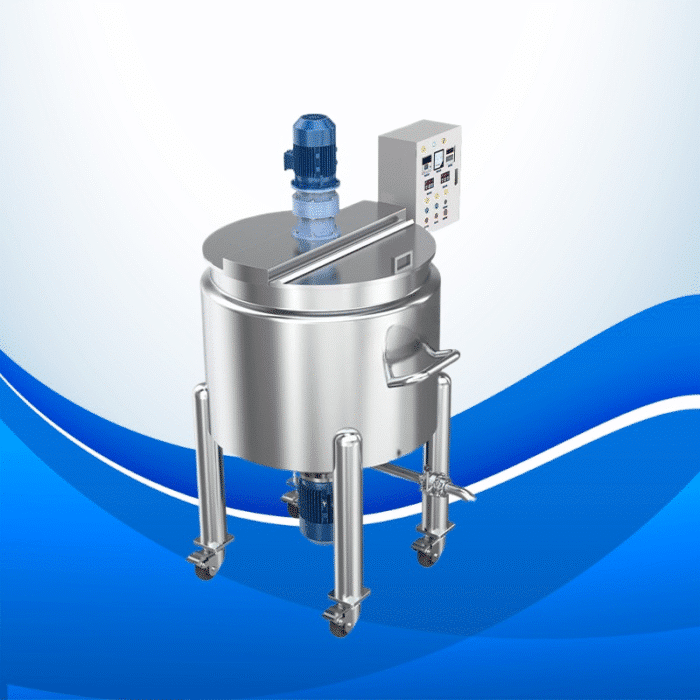

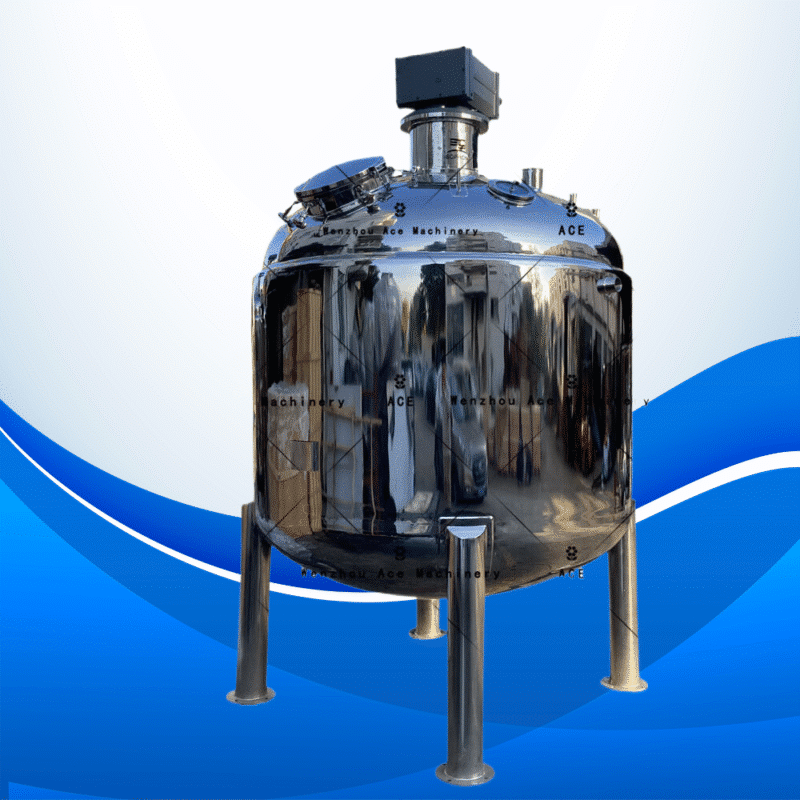

Product Description: Liquid Mixing Tank

Overview:

A liquid mixing tank sits at the center of many factories, letting operators stir together liquids, powders, and similar materials until everything looks and acts the same. From breweries and juice bottlers to drugmakers, chemical teams, and cosmetic brands, every business counts on dependable mixing tanks to keep lines running smoothly. By using this gear, companies boost product quality, speed up output, and stick to safety rules that customers and workers expect.

Our tanks are built with options, meaning you can tweak size, material, and motor strength so the unit fits your operation. Pick the mix that matches your load, and trust that the package will deliver as promised. Flip through the following sections to see features and benefits that have already won our tanks a spot on shop floors worldwide.

Key Features and Benefits of Our Liquid Mixing Tanks:

Power to Match Your Process (1.5 kW to 55 kW)

No matter if you mix paint in a workshop or chemicals in a factory, our tanks give you power that fits your job. Units run from a gentle 1.5 kW for thin liquids clear up to heavy 55 kW for thick pastes. The strong motors tear through viscous batches, while milder settings handle lighter items with ease.

Voltage to Suit Your System (110 V to 600 V)

Every tank can be wired for the voltage you have, from 110 V household lines all the way to 600 V industrial feeds. This flexibility lets you plug the mixer into almost any regional grid without headaches. North America, Europe, Asia—each area gets a setup that starts quickly and runs steadily.

Built to Last (316L/304 Stainless Steel)

What shows up on your shop floor is only as good as the steel it is made from, so we use food-grade 304 or marine-grade 316L for every tank. 316L resists rust from harsh chemicals, heat, and pressure, so it sits safe in pharmaceutical, chemical, and food plants. 304 serves well where mild purity matters and costs need to stay down.

304 stainless steel keeps the price reasonable while still working well in everyday settings like water treatment, cosmetics, and low-risk liquid lines.

Superior Mixing Efficiency

Our tanks come with smart mixing tech that stirs liquids fast and evenly, whether you need an emulsion, suspension, or fully blended batch. You get strong, uniform blends without burning extra juice.

Enhanced Durability & Safety

Top-quality stainless steel gives our tanks tough armor against wear, rust, and high heat. Pressure-release valves and easy-to-reach controls add extra layers of safety so the unit runs smooth even on the busiest days.

Versatile Applications

Liquid mixing tanks show up all over the place, in:

- Food and Beverage lines, for dressing, sauces, smoothies, and dairy.

- Pharma labs, where they help make medicines and active solutions.

- Beauty shops, mixing creams, gels, and lotions.

- Paint and chemical plants, for even blends of glues, dyes, and pigments.

- Water-treatment docks, prepping chemicals for cleaner, safer supply.

Applications and Scenarios:

Picture running a busy kitchen or bottling plant where the same batch has to taste and look the same, batch after batch. Our liquid mixing tank steps in and blends sauces, juices, or dressings quickly and evenly, freeing your team to handle other tasks. In the drug-making world, the same tank works quietly in the background, making sure every suspension or cream is blended to the exact recipe so it meets safety tests.

On the factory floor, whether you’re pouring syrupy food additives or thick resin into the pipe, our tanks tackle sticky, heavy liquids without slowing down. Because they come with adjustable features, the system can slip into almost any line and pick up the pace right away, no matter the output you aim for.

Why Choose Our Liquid Mixing Tanks?

- Customization Options: Built to your chosen power supply, tank size, and material-grade—from stainless steel to plastic.

- Efficiency & Reliability: Engineered for repeatable performance so you never scrap a batch.

- Durability: Frame and motor sealed and tested to shrug off spills, steam, and 24-hour use.

- Versatility: Approved across food, pharma, chemicals, and more with quick changeovers.

Investing in our system means your line stays fast, waste drops, and sudden recipe tweaks can be handled without new equipment. A smart mixing solution pays back through fewer rejects, tighter schedules, and, ultimately, bigger profits.

Call to Action:

Want to speed up your mixing line with a high-tech tank? Reach out to us, and we’ll help you design the perfect unit, then get your order moving. Whether you’re swapping out old gear or starting from scratch, our crew stays with you from planning to setup. You get fair pricing and know-how, so your new tank pays off for years.

Frequently Asked Questions:

1. Can I customize the size of the liquid mixing tank?

Definitely! Our tanks come in lots of sizes, so we’ll match one to your space and output. Just share your capacity and floor plan, and we’ll send the specs you need.

2. What is the difference between 316L and 304 stainless steel?

316L handles salt, acids, and tough wash downs better than 304, making it great for harsh fluids. If your blend is less aggressive, 304 saves money and still works well for every day mixing.

3. How do I select the right power and voltage for my tank?

No guesswork—you tell us where the tank will plug in, and we recommend the wattage and volts. Choices range from 1.5KW at 110V all the way up to 55KW at 600V, so we fit almost any site.

4. Do you set up the tank for me?

Absolutely! When you order one of our liquid mixing tanks, our friendly crew comes out to your site and installs it. They’ll double-check all the connections, so the tank runs perfectly from day one.

Wrap-Up:

Picking the right mixing tank can really speed up your workflow and make your products safer and more even. Because each unit can be built to fit your space and job, it works hard no matter what line you are in. Reach out now, and we’ll craft a solution that fits your team exactly.