Introduction: A Smart Choice for Steady Mixing

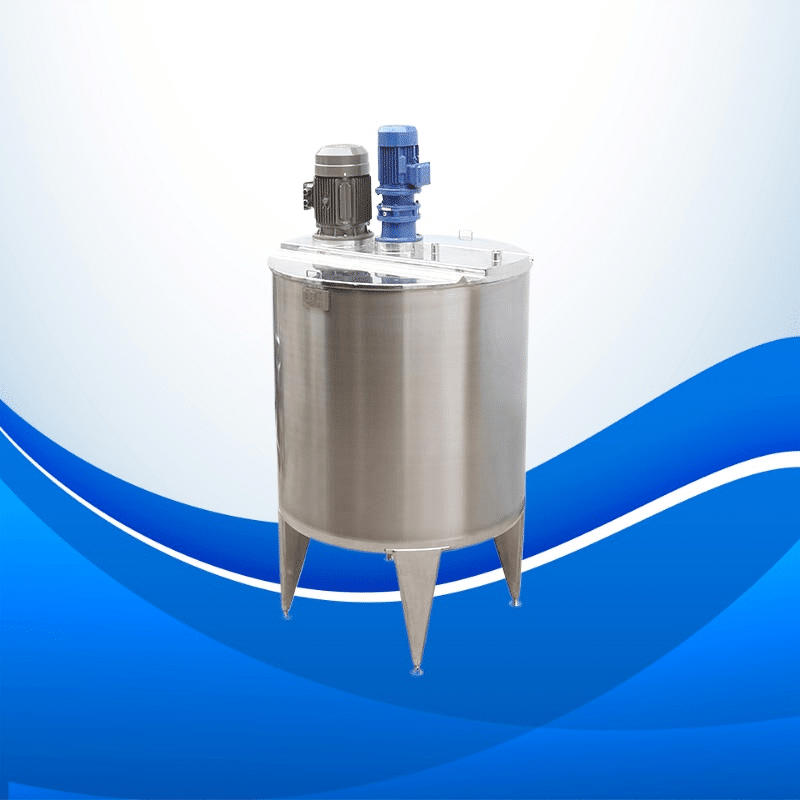

When you need spot-on mixing that lasts, a 300-gallon stainless-steel tank is hard to beat. Whether you’re blending food, whipping up lotions, handling industrial chemicals, or making meds, this tough tank keeps every batch uniform, even in rough settings. Built to grow with your line, it slides into almost any production setup without a fuss.

Key Features at a Glance (Approx. 150 words)

- Capacity: 300 gallons, or roughly 1,135 liters

- Material Choices: Top-grade 316L or standard 304 stainless steel

- Power Ratings: From 1.5 kW for light work to 55 kW for heavy jobs

- Voltage Options: Runs on anything from 110V house current to 600V three-phase

- Mixing Gear: Adjustable-speed paddles, one-piece or custom blades

- Certs: Meets FDA, GMP, and ASME standards if you ask early

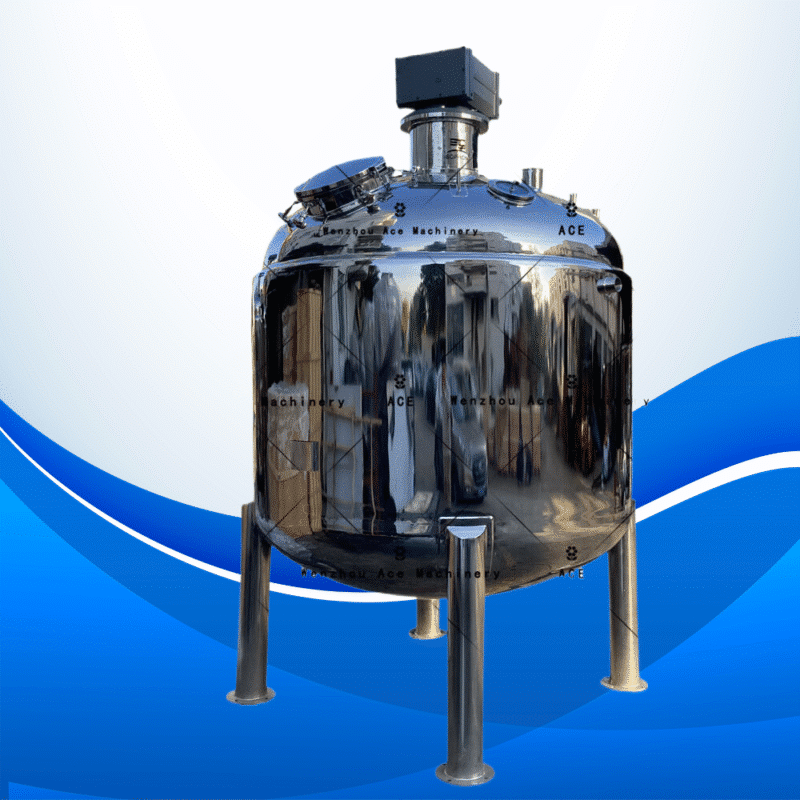

- Finish: Shiny mirror polish for clean rooms or matte for factory floors

- Mobility: Permanent install or breeze-around skid-mount layout

More than just a tank, this 300-gallon unit is a rugged, go-all-day mixing system.

Applications in Real-World Scenarios (Approx. 250 words)

Knowing where a 300-gallon stainless-steel mixing tank fits into everyday work helps buyers see what they really get. Here are the main places you’ll find it:

1. Food and Beverage Production

The tank’s clean, welded seams keep sauces, syrups, dairy, oils, and drinks safe while they mix. Add-on heating jackets let operators raise or lower temp during blending or pasteurizing.

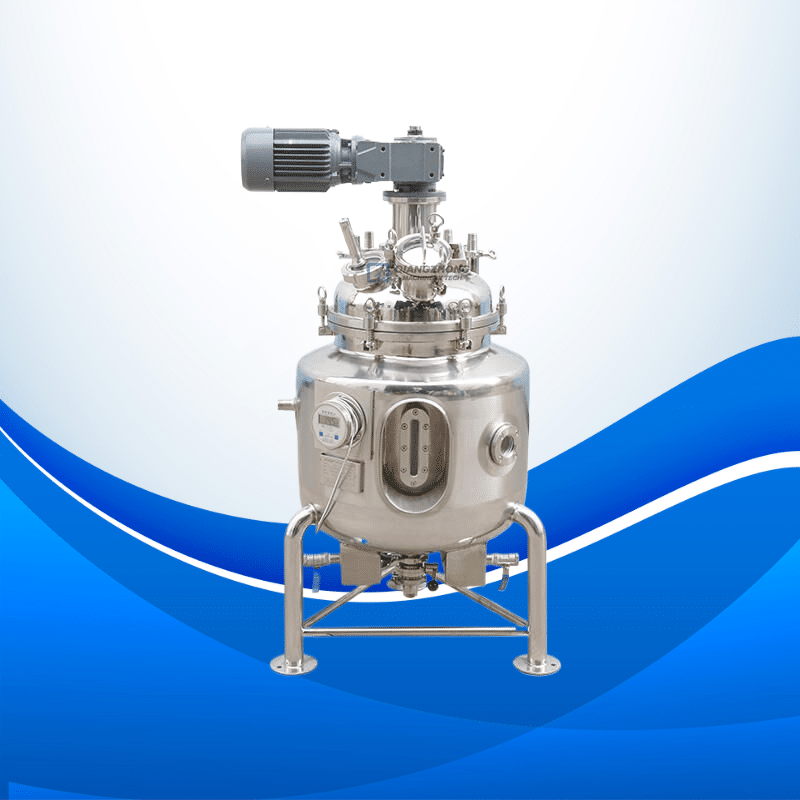

2. Pharmaceutical Manufacturing

Used for suspensions or liquid meds, the tank meets all good-manufacturing practices. Smooth walls and special drain points work with clean-in-place systems, so crews spend less time between batches.

3. Cosmetics and Personal Care

When making lotions, shampoos, or gels, even tiny texture changes matter. Variable-speed agitators let formulators blend without over-shearing, keeping color, smell, and stability on track.

4. Chemical Processing

Grade stainless steel fights rust and reacts slowly, so the tank handles solvents, acids, and tough polymers. For extra peace of mind, buyers can order explosion-proof motors in hazy areas.

5. Brewing and Fermentation

Small to mid-sized breweries and kombucha shops like the tank’s size because it sits between home-brew and full-scale systems. Built-in sensors offer steady temp and pH readouts, helping each batch taste the same.

Customization Options to Fit Your Workflow (Approx. 250 words)

Every production floor has its own rhythm. Because of that, our 300-gallon mixing tank comes with a full menu of custom features:

Material Choice

- 316L Stainless Steel offers the highest corrosion resistance and is great for pharmaceutical or acidic batches.

- 304 Stainless Steel is the affordable pick for food-grade, water-based, and non-reactive products.

Voltage Compatibility

Motors can be wired for any world market: 110V, 220V, 380V, 415V, 480V, or 600V, in either single-phase or three-phase.

Power Selection

Power ratings stretch from 1.5 kW for gentle mixing up to 55 kW for full high-shear emulsification.

Agitator Types

- Pick from paddle, anchor, turbine, or high-shear impellers.

- Choose motors that enter from the top or under the tank lid.

Tank Finish

- Select a mirror polish for hygienic lines or a matte brush finish for general industrial use.

Additional Features

- Add heating and cooling jackets

- Load cells for weight readouts

- Automated controls with PLC and touchscreen

- Manholes, baffles, and sight glasses.

Whether replacing an old unit or launching a new line, this tank can be shaped to your process flow.

Operational Benefits and ROI (Approx. 200 words)

Investing in a 300-gallon stainless-steel mixing tank isn’t just a capital expense—it’s a decision to enhance product quality and operational efficiency.

Benefits Include:

- Consistent Product Quality – High-precision mixing means every batch tastes and feels the same.

- Hygienic Design – Clean-out crevices are gone, so you scrub less and start the next run sooner.

- Energy Efficiency – Power-smart motors trim the electricity bill without losing torque.

- Scalability – The 300-gallon model slides into pilot setups or full lines with the same hoses.

- Durability – All-stainless build fights rust, giving you more time on the floor and fewer repairs.

- Compliance – Certified to meet food, pharma, and chemical rules worldwide, so audits are quick.

After a few months, owners see tighter quality, lower scrap, and a clear bump in ROI.

Why Choose This 300-Gallon Mixing Tank? (Approx. 200 words)

- Built for Performance – Yielding heavy workloads, its incompressible frame shrugs off daily punishment.

- Versatile Application – Cocktail bases today, lotions tomorrow – feed tube swaps let you pivot fast.

- Service and Support – Windows-centered control keeps troubleshooting simple, and spare parts ship next day.

- Competitive Pricing – A mid-market rate that balances smart long-term value with front-end budget.

This tank is not a one-size-fits-all; it is a made-for-you component that will boost your entire line.

Order & Customization Process (Approx. 150 words)

Getting your tank ordered and set up is simple and quick: First, you have a chat with us to explain what you need—how you plan to use the mixer and any special features you want. We then whip up a detailed quote, complete with drawings and all the specs, so you know exactly what you are getting. Once you give the thumbs-up, production kicks off, and every step is watched closely to make sure quality never slips. When the tank is ready, we ship it anywhere in the world, and you can choose to have our team help with installation on-site. Even after delivery, our friendly support crew is just a call or email away for any questions, upgrades, or troubleshooting. You will find that we work with tight schedules and special compliance rules all the time—whether you are expanding or replacing old gear, we are here to make it smooth.

Call to Action: Ready to Upgrade Your Mixing Process?

Experience the quality, consistency, and flexibility only a 300-gallon stainless steel mixing tank can deliver. From food and pharma to chemicals and cosmetics, this is the solution trusted by industry leaders.

📩 Contact us today for a free consultation or to request a custom quote.

✅ Volume discounts and expedited production available!

Frequently Asked Questions

Q: Can the tank handle high-viscosity materials?

Yes, the right agitator and motor mix even very thick products like creams or gels with no problem.

Q: Is it suitable for acidic or reactive contents?

Absolutely—opt for 316L stainless steel to stop corrosion cold over the tank’s whole life.

Q: What certifications do you have?

We can provide motors that meet FDA, GMP, ASME, or CE rules, so you get the paperwork you need for your industry.

Q: How do I pick the right motor power?

Our engineers look at material thickness, volume, and how fast you want to mix, then work out the best kW for you.

Q: What’s the lead time?

Production usually runs about 4 to 8 weeks, but it can go faster for rush orders that customers request.