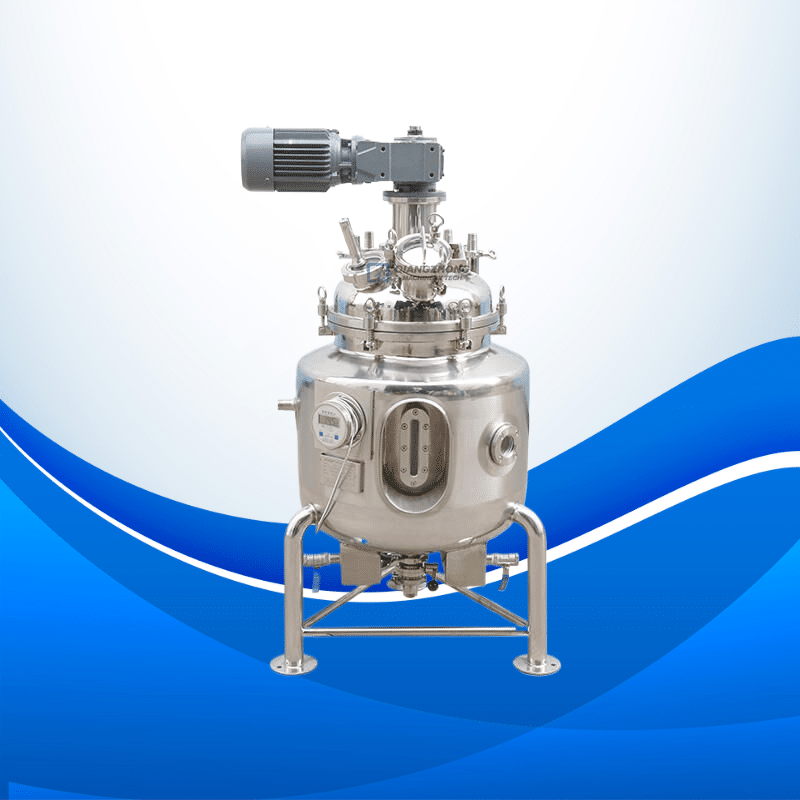

Dimple Jacketed Mixing Tank

- Capacity: 50 liters to 30,000 liters

- Mixer power: 1.5 kW to 55 kW

- Material: 304 or 316L

- Voltage: 110V to 600V

- Heating method: Electric or steam heating

- Layer:single/double jacket/three jacket

- Mixer types: Impeller-type, Anchor-type, Turbine-type, High-shear-type, Magnetic mixer, Anchor-type mixer with scrapers,dispersing

- Optional: platform, wheels, ladder,variable frequency drive,explosion-proof device

- Certificates: ASME, CE, GMP, UL, ATEX, ISO 9001

- Our equipment supports customisation, global delivery, and a 1-year warranty.

- If you have drawings, we can process them for you.

Note: Please contact our sales team before placing an order. Website prices are for reference only; specific pricing requires understanding your requirements to provide a quote.

Email:info@ace-chn.com

Tel: +86 186 2683 5909

WeChat: ace-chn

WhatsApp: +86 186 2683 5909

$4,333.00

Guaranteed Safe Checkout

Recommend RPM: 0-960RPM

Viscosity: Low/medium viscosity

Application: Mainly Liquid mixing

Recommend RPM: 0-200RPM

Viscosity: Low/medium viscosity

Application: Mainly Liquid mixing

Recommend RPM: 30RPM

Viscosity: Medium/High viscosity

Application: Melting, High viscosity product mixing, For single wall tank

Recommend RPM: 30RPM

Viscosity: Medium/High viscosity

Application: Melting, High viscosity product mixing, For jacket tank

Recommend RPM: 1480/2850 RPM

Viscosity: Low/medium viscosity

Application: Liquid powder mixing and dispersion

Recommend RPM: 1480/2850 RPM

Viscosity: Low/medium/High viscosity

Application: Liquid powder mixing and homogenizing

Recommend RPM: 0-355RPM

Viscosity: Low/medium viscosity

Application: Install at bottom, No mechanical seal working condition

Recommend RPM: As above

Viscosity: Low/medium viscosity

Application: Liquid powder mixing and dispersion For tank volume >300L

Dimple-Jacketed Mixing Tank: Smart, High-Efficiency Gear for Industrial Mixing

A dimple-jacketed mixing tank is a workhorse that mixes, heats, and cools with the same unit, solving a lot of tricky process problems across the factory. The tanks feature a pattern of dimples pressed into the shell, creating narrow flow channels that carry warm or cold fluid all around the vessel and lift the product off the bottom. Because of that steady circulation, operators can hold the mix at the right temperature whether the run is small-batch or big continuous flow, making the tank useful in food, pharma, chemical, and beauty-cosmetic lines.

Key Features of a Dimple-Jacketed Mixing Tank

Enhanced Heat Transfer

The dimple loop moves fluid fast, so hot spots and cold zones are practically gone. That even heating-or-cooling is vital when recipes include sensitive drugs or fine chemicals whose quality depends on exact temperature holds.

Versatile Material Options

Tanks come in either 316L or 304 stainless steel, both of which shrug off rust and last a long time even in hard-use, high-pressure, or really hot spots. So whether the process is pouring acid or running steam through the jacket, customers get the strength and peace of mind they expect.

Custom Size and Power Options

Not every business runs the same way, so our dimple-jacketed mixing tanks can be built to match your setup. You can pick from motor sizes between 1.5 kW and 55 kW and voltage levels from 110 V to 600 V, giving you the right muscle for the job.

Steady, Even Mixing

The tanks are shaped to give you steady, even mixing every time, even with recipes that have a wide range of thickness. The built-in stirrer ties together liquids and materials that used to settle on their own.

Tough and Long-Lasting

Made for nonstop factory work, the dimple jacketed tank is a heavy-duty piece of gear. Its strong frame and top-grade materials shrug off rough weather and keep running day and night.

Quick to Clean

Because the tank was designed with the operator in mind, a wipe-down or quick check takes only minutes. That keeps the line moving and cuts the hours you spend fixing, not making.

Applications of Dimple-Jacketed Mixing Tanks

Dimple-jacketed mixing tanks are so flexible that you can find them in lots of different factories and labs. Here are a few of the most common places they show up:

Chemical Processing

When operators work with unstable or sensitive chemicals, they rely on dimple-jacketed tanks to keep every batch at the perfect temperature. This extra control helps the ingredients mix smoothly and keeps the final product up to quality standards.

Food and Beverage Industry

Makers of sauces, syrups, or dairy goods use these tanks because the built-in heating transfers energy evenly and quickly. That way, nothing burns and the blend stays thick and tasty from start to finish.

Pharmaceuticals and Cosmetics

Factories that produce creams, lotions, or ointments cannot afford small temperature swings. With dimple jackets, the mixer runs at the planned heat level, keeping every container the same right to the sealing line.

Paints and Coatings

Paint and craft-coating lines count on the fast, steady agitation to fold pigments together and melt any lumps. The jacket stops hot spots, so color and texture stay consistent batch after batch.

Biotechnology

Cell cultures and fermentation strains need stable, friendly conditions to grow strong. The tank’s tight heat and mix control give researchers nearly the same environment every test, improving data and saving time.

Why Pick Our Dimple Jacketed Mixing Tank?

Custom-Fit Options

Every plant does things a little differently, so we let you pick the height, motor size, and even the steel grade. This way, you get a tank that fits your line and your job, not the other way around.

Better Efficiency

Because heat or chill moves quickly through the dimple panels, our tank cuts warm-up time and cool-down time. That fast transfer saves power and keeps your mix on schedule.

Rugged, Long-Lasting Build

Made from either 316L or 304 stainless steel, the tank laughs at rust, dents, and harsh cleans. With proper care, it works like new long after cheaper models begin to fail.

Consistent High Quality

Careful mixing and steady temperatures mean your batches look and taste the same each time. Fewer surprises at the end of line help you keep customers happy and complaints low.

Product Specifications

- Voltages: 110V to 600V

- Power Output: 1.5KW to 55KW

- Body Material: 316L or 304 Stainless Steel

- Tank Style: Dimple-jacketed for fast heat spread

- Speed: Set to match your mixing job

- Temp Range: Works for both heating and cooling

- Use In: Chemicals, food, meds, beauty, biotech, and more

Call to Action: Order Your Custom Dimple-Jacket Tank Today

At [Company Name], we build dimple-jacket tanks that fit the way you work. Whether you need a tank for small batches or a giant line, we’ve got the right option ready for you.

Buy now to enjoy quick heat-up, smooth mixing, and less energy waste. Reach out for a quote, and check out the features we can add to suit your system.

Frequently Asked Questions (FAQ)

1. What is a dimple-jacketed mixing tank used for?

A dimple-jacketed mixing tank is used to stir and warm liquids or slurries when keeping the right temp is critical. It’s perfect for chemicals, drugs, food, drinks, and beauty products.

2. What voltage and power options do you offer?

Our tanks can be wired from 110V all the way up to 600V, and they come in power ratings between 1.5 KW and 55 KW, so you can pick the setup that fits your plant.

3. Which material should I choose for my mixing tank?

You can pick either 316L or 304 stainless steel based on the liquids you work with. 316L resists rust better and is great for harsh chemicals or salty brines, while 304 works fine for most everyday products.

4. Can the mixing tank be customized?

Absolutely. Size, mixing speed, heating power—almost every part of the tank can be modified to meet your exact needs.

5. How long does the tank last?

If you do the regular cleaning and inspections, our dimple-jacketed tanks should give you ten years or more, thanks to heavy-duty stainless steel and great anti-corrosion features.