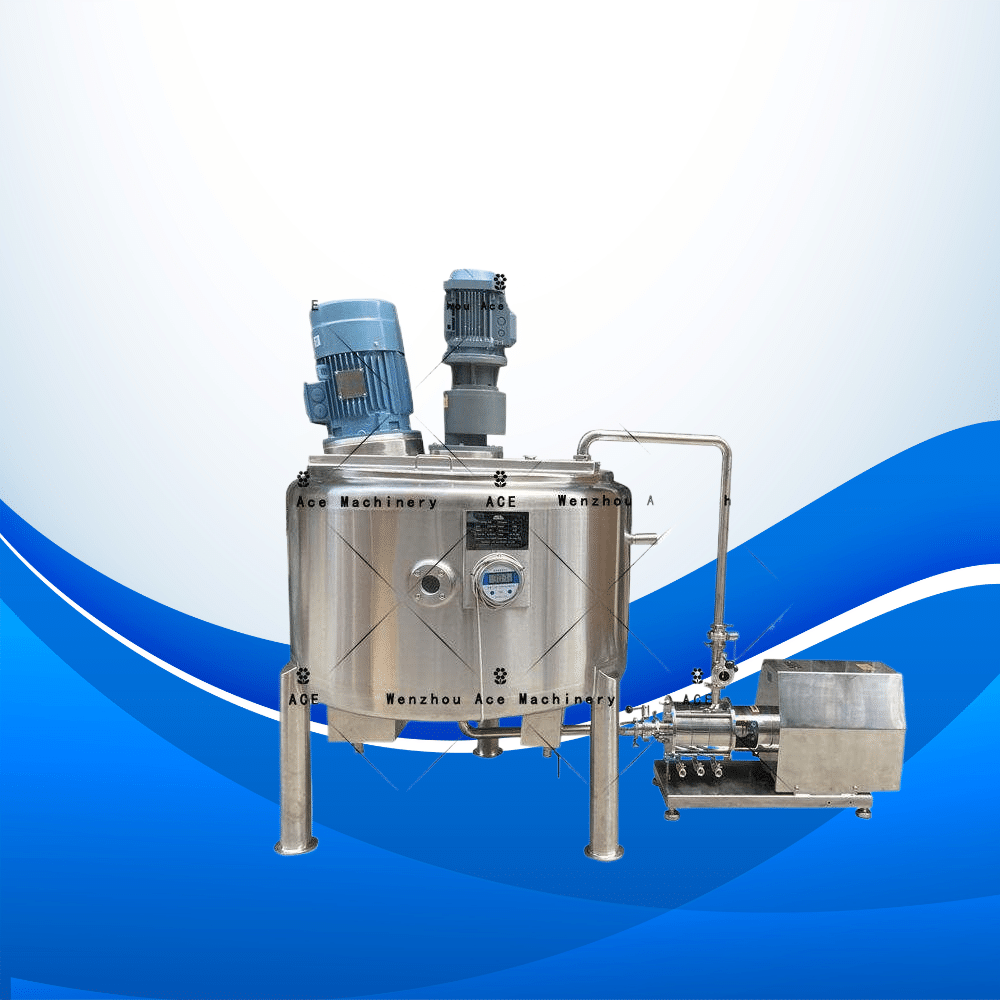

500L Mixing Tank: The Go-To Mixer for Heavy-Duty Jobs

When heavy-duty mixing is on the line, the 500L Mixing Tank usually earns top marks because it just works. Whether you’re blending ingredients for a new soft drink, combining pharmacy compounds, crafting lotion batches, or stirring up chemical formulas, this tank offers speed, strength, and room to flex.

This piece breaks down the tank’s main perks, common uses, and add-on options, so you know exactly what you get before any purchase.

1. Quick Look at the 500L Mixing Tank

Engineered to handle half a ton of liquid, the 500L Mixing Tank delivers powerful, even blending for everything from big jars of syrup to fine powder batches. Its tough design fits both stop-start and nonstop lines, and pool-plate controls make set up a breeze, so teams spend less time wrestling with machines and more time growing products.

This heavy-duty mixing tank was built to whip everything together smoothly, giving you the same mix in every corner of the drum. Because its blades, motor speed, and other settings can be tweaked, the mixer quickly suspends solids, breaks down emulsions, or keeps delicate powders from lumping when you work on small to medium batches.

2. Top Features and Benefits

2.1 Reliable Mixing Speed

Inside, a high-torque motor spins advanced impellers that pull material from top to bottom. Whether your recipe includes dyes, dressings, or active ingredients for tablets, the 500-liter tank cuts blend times while protecting sensitive ingredients, so you get even color, texture, and potency with every batch.

2.2 Plug-and-Play Power Choices

Power ratings from 1.5 kW to 55 kW, plus voltages between 110 V and 600 V, let you tap the capacity your process truly needs. That way the mixer works quietly, your electrical panel stays cool, and you keep power costs in check.

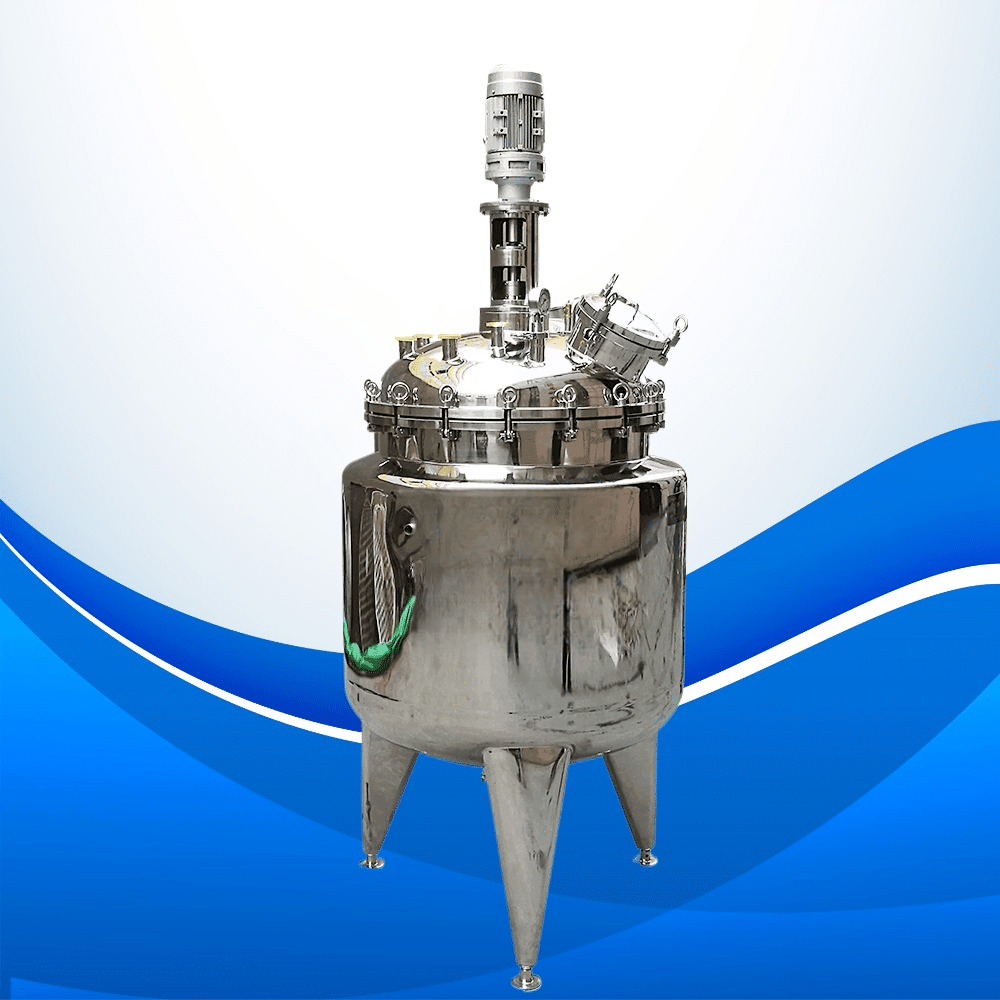

2.3 Solid Build with Quality Stuff

The 500L Mixing Tank is built using two top-notch steel choices: 316L and 304 stainless steel. Both types fight rust really well, so the tank lasts a long time and stays safe no matter the setting. Because 316L adds an extra layer of protection, it is the go-to choice in food and pharmacy spaces where cleanliness rules are strict.

2.4 Simple to Clean and Look After

Thanks to its smooth walls, tight seals, and open layout, the 500L Mixing Tank is a breeze to clean and keep up with. That easy upkeep cuts downtime, boosts output, and helps everyone stay on the right side of safety and hygiene rules.

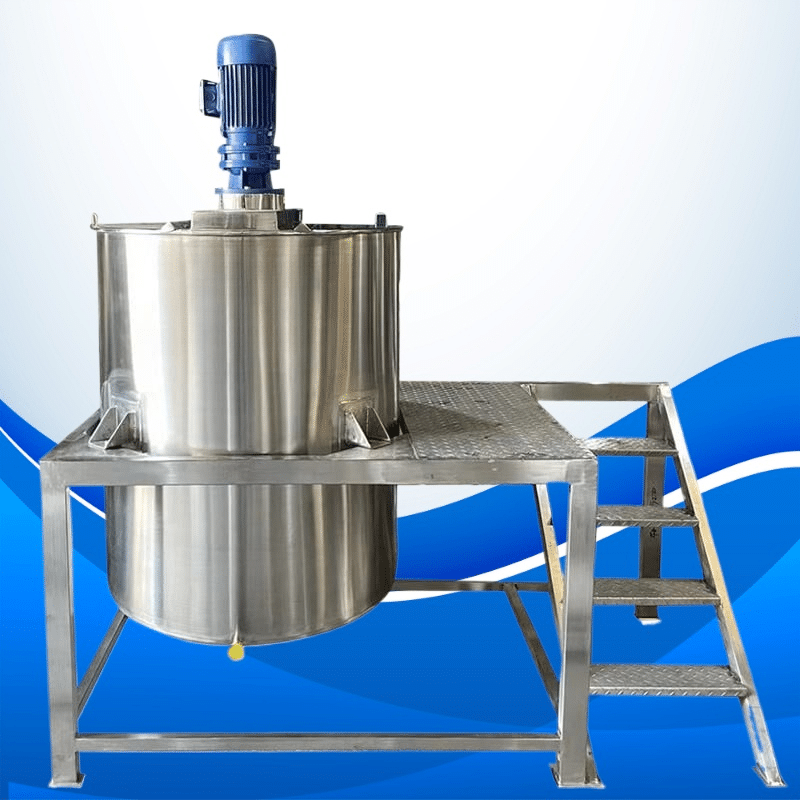

2.5 Smart, Compact Shape with Big Capacity

Even with a big 500-liter volume, the tank is built to save space. Its slim profile slides into tight production rooms without giving up power, so it works great in shops that are short on floor area.

3. Applications in Different Industries

The 500-liter mixing tank is handy in many different factories and workshops, and it proves itself almost everywhere. Here are some day-to-day places you will find the tank in action.

3.1 Food and Beverage Industry

Bakers, brewers, and snack-makers keep the 500-liter tank busy stirring, whipping, and mixing everything from batter to bubbly drinks. With smooth welds, rounded corners, and quick-clean ports, it slips easily into any kitchen that has to follow tight health rules.

3.2 Pharmaceutical Manufacturing

Drug companies rely on the 500-liter tank when they need to mix liquid medicines, suspensions, or uniform creams. Because customers can choose either 316L or 304 stainless steel, the tank meets all Good Manufacturing Practice paperwork and keeps quality controls in line.

3.3 Chemical Industry

Paint shops and dye houses count on the 500-liter tank to marry pigments, solvents, and additives so colors come out exactly right every time. By swapping motors or adjusting voltage, engineers can fine-tune the setup for strong, reliable mixing of every formula the plant makes.

3.4 Cosmetics Industry

In the cosmetics world, people count on the 500L Mixing Tank to whip up everything from face creams to body wash and shampoo. Because it mixes fast and can move between thick pastes and thin liquids, each batch comes out the same every time. The tough build means the tank keeps working day after day, even in busy factories that never stop.

3.5 Agricultural and Fertilizer Production

Farm suppliers also turn to the 500L tank when they need to blend pesticides or make batches of fertilizer. With choices in size, ports, and lining, the tank can be set up to handle almost any farm formula, including some really harsh chemicals.

4. Custom Builds and Tech Specs

The 500L Mixing Tank comes with a bunch of options, so you can set it up the way you want. Check out the main specs:

- Capacity: 500 Liters

- Material Choices:

- 316L Stainless Steel (top corrosion resistance; great for food, drugs, or chemicals)

- 304 Stainless Steel (flexible use, works fine in most industrial jobs)

- Power Range: from 1.5 kW to 55 kW (exact size matched to your energy plan)

- Voltage Range: from 110V up to 600V (fits nearly any outlet or panel)

- Mixing Speed: fully adjustable for different recipes

- Standard Speed Range: 0-100 RPM (broader range on request)

- Design Features:

- Top or bottom discharge

- Smooth, sanitary surfaces

- Full lid with viewing window

- Built-in temp and pressure controls

- Safety Gear:

- Overload protection

- Anti-splash cover

- Pressure relief valve

These tailored choices let the 500L Mixing Tank fit any industry you work in.

5. Why Our 500L Tank Is a Smart Pick

With decades in the game, we build the 500L Mixing Tank for rock-solid performance, long life, and real versatility. Here are a few reasons to go with us:

- Expert Engineering: Our team uses cutting-edge tech, so every tank runs smoother and lasts longer.

- Custom Options: Pick the power, voltage, and material you need, then we build it just for you.

- Proven Quality: Built from tough 316L and 304 stainless steel, every tank is made to stand up to heavy everyday use.

- Reliable Support: Our team helps you from set-up through regular checks, so everything runs the way it should.

6. Frequently Asked Questions

Q: What industries can benefit from the 500L Mixing Tank?

A: Food and drink factories, drug companies, beauty product makers, chemical plants, and even farms all find it useful.

Q: Can the tank be customized to my specifications?

A: Yes, we offer customizable power, voltage, and material options to meet the unique needs of your business.