Product Description:

Vacuum Mixing Tank: Your Go-To Buddy for Perfect Blends Every Time

A vacuum mixing tank is the go-to gadget anyone serious about making thick pastes, powders, or liquids will want on the plant floor. Whether you mix medicines, bottled drinks, or industrial chemicals, these tanks let you work fast yet keep each batch clean and bubble-free. If your recipes need sharp attention to detail or if reject rates cost you money, our tanks are built to handle the toughest daily demands with ease.

Key Features of Our Vacuum Mixing Tank:

Hands-Free Vacuum Control:

Every time you pull a vacuum, air pockets shrink, oxidation slows, and tiny particles of dust stay outside where they belong. That’s why food makers and drug firms trust this feature; it turns a tricky job into a repeatable, on-spec process.

Material that Fits Your Needs

Our vacuum mixing tanks come in two solid stainless-steel grades: 316L and 304. You’ll want 316L if your process faces strong acids or salts, so it’s a favorite in pharma, chemicals, and food plants where clean parts matter. The 304 option handles lighter duties, stays tough over time, and costs a little less.

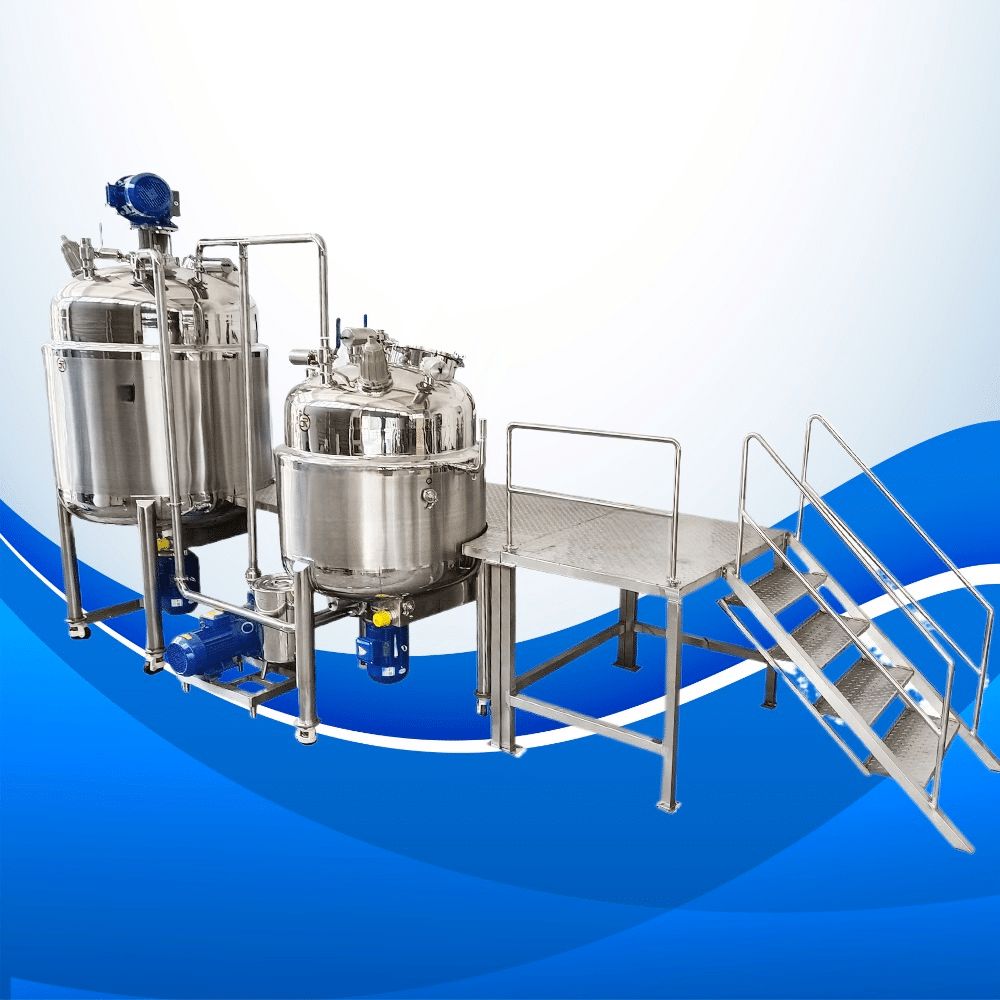

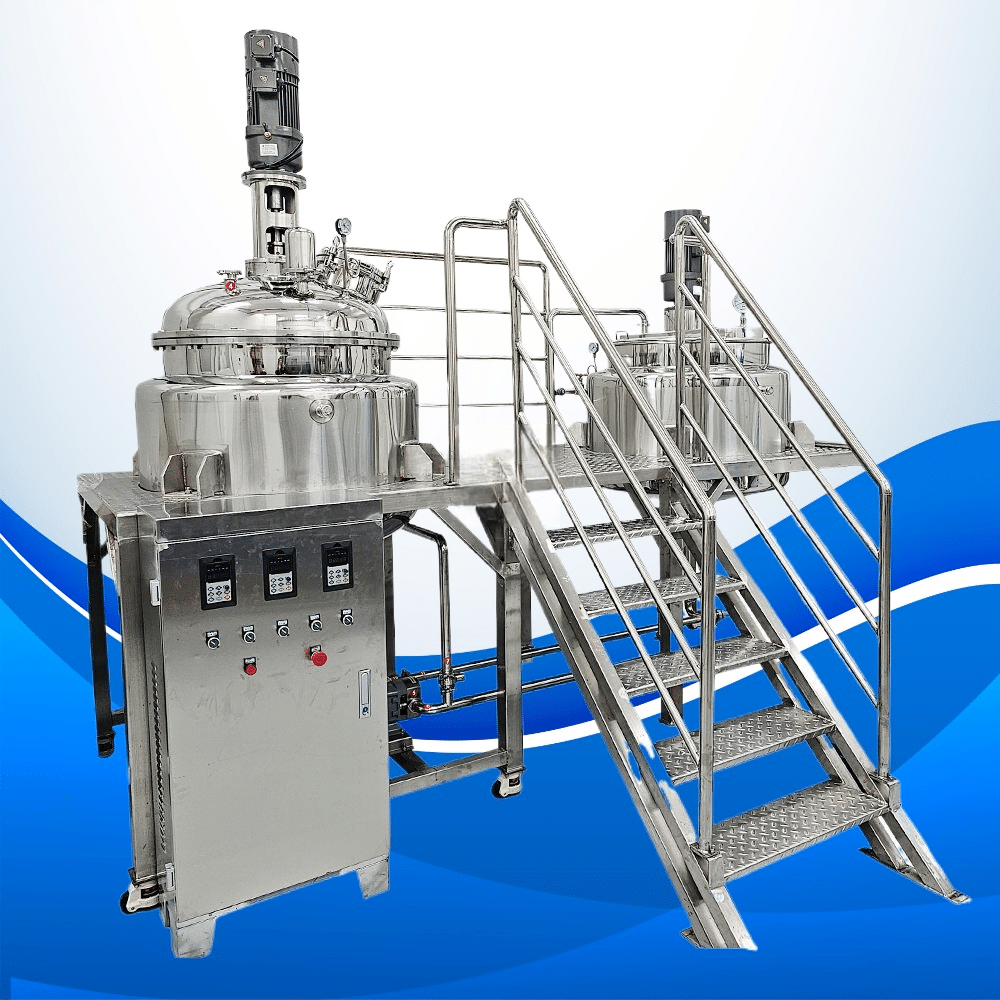

Power That Matches Your Scale

We know every line runs at its own pace, so we offer motor sizes from 1.5 kW for small batches up to 55 kW for high-output plants. That range lets the same tank work wherever you start. We’re also flexible with voltage, from 110 V to 600 V, so you can plug it into the supply you already have.

Mixing Done Right and Fast

With its modern blades and smart pump layout, the tank intends ingredients fast yet wastes almost no power. Even thick pastes flow smoothly, meaning you get the same quality jar after jar-and blueprints for the next jobs are secure.

Customizable Features:

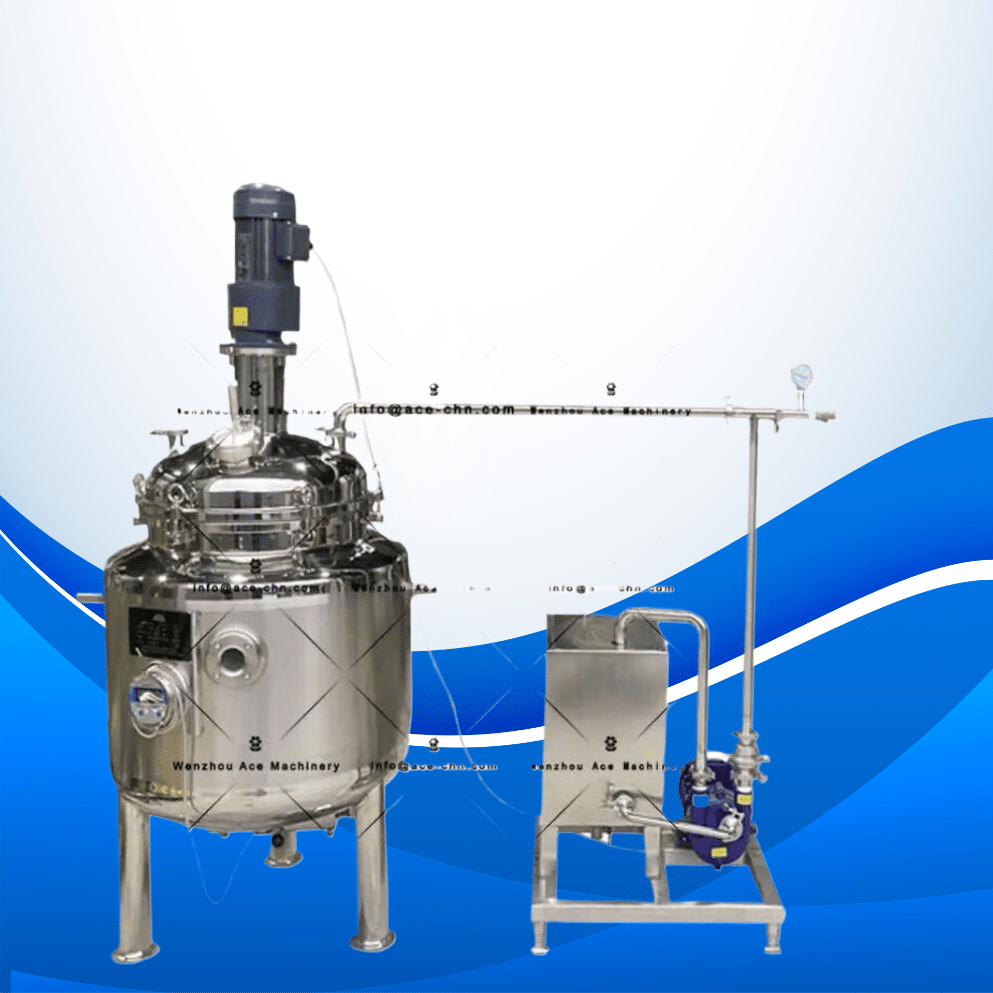

Every business is a little different, and we get that. That’s why our vacuum mixing tanks come with options like mixers, agitators, temperature controls, and built-in pumps so you can set the unit up exactly how you need it and get the best work out of it every day.

Applications and Use Cases:

Pharmaceutical Industry:

When you make medicine, every tiny detail matters and cleanliness is a must. Our vacuum mixing tank blends powders, liquids, and suspensions in a sealed space, keeping air out so the product stays pure. That controlled environment helps active ingredients mix evenly, giving you higher-quality meds in each batch.

Food and Beverage:

Food factories use the tanks to stir together sauces, soups, dairy, and more. By working under a vacuum, the mixer locks in flavor, color, and nutrients, so every jar or bottle comes out tasting and looking the same every time.

Cosmetics and Personal Care:

Cosmetic makers count on the tanks to whip up creams, lotions, and serums that feel nice on skin. The vacuum traps no air bubbles and slows oxidation, letting you sell products with smooth texture and longer shelf life.

Chemical Processing:

When companies make things like adhesives and paints, they usually deal with really thick liquids that hate to mix. A vacuum mixing tank steps in here by swirling those high-viscosity materials together while sucking out air. Doing it this way keeps the chemical makeup steady and lifts the overall quality of the finished product.

Advantages of Using a Vacuum Mixing Tank:

Air-Free Mixing:

Because the process happens under a vacuum, no tiny bubbles sneak in. This leaves a smooth, clear batch that stays mixed longer and performs better.

Enhanced Quality Control:

A blend that stays free of dust and trapped air means the product acts exactly as designers promised, a must-have for industries with tight specs.

Energy Efficiency:

Users can dial down the motor when a lighter mix is needed, so the tank does heavy work without hammering the power bill.

Durability:

Constructed from top-grade stainless steel, the tank laughs at rust and scratches, giving years of reliable use even in tough shop floors.

Ease of Maintenance:

Nothing complicated inside, so operators can wipe it clean quickly and spend almost no time waiting for repairs.

Technical Specifications:

- Material Options: Pick either 316L stainless steel for salty or acidic jobs, or go with 304 steel for everyday work.

- Voltage Options: Available in 110V, 220V, 380V, or 600V to match any plant setup around the globe.

- Power Options: Ranges from 1.5KW for small batches up to 55KW for large runs, so there is a fit for every production scale.

- Mixing Speed: Managers can set the paddle speed to match a specific product, whether syrupy or almost solid.

- Capacity: Each vacuum mixing tank is built just for you, whether you need a small lab unit or a big industrial system.

Why Pick Our Vacuum Mixing Tanks?

Custom Design Options:

No two jobs are the same, and we get that. Our engineers will team up with you to create a tank that fits your process-whether you work with food, drugs, or chemicals.

Expert Support:

From the first phone call to final installation, our support crew has your back. Well, stay close, so your new gear spends more time working and less time idle.

High-Quality Assurance:

Every tank leaves our floor crafted to tough safety and performance standards, giving you the peace of mind to focus on your business.

Global Reach:

Wherever you are on the map, we can ship your tank and connect you with local experts who will help set it up and keep it running.

Frequently Asked Questions (FAQs):

Q1: What types of materials can I mix with a vacuum mixing tank?

A: Pretty much anything you can think of: powders, liquids, creams, gels-even super-thick stuff. People use them in food, pharma, cosmetics, and chemical plants all over the world.

Q1: Can I pick a tank size that fits my space?

A: Absolutely! Our vacuum mixing tanks come in standard sizes, and we can tweak dimensions to match your shop floor layout.

Q2: Why bother with a vacuum when mixing?

A: Pumping out the air cuts oxidation and keeps dirt out, so every batch blends evenly. That matters a lot for fragile stuff like drugs and food.

Q3: Is looking after a vacuum mixing tank a chore?

A: Not at all. Every unit snaps apart for quick wipe-downs, and we throw in easy guides plus friendly tech support.

Q4: What power and voltage options can I pick?

A: Tanks range from 1.5 kW to 55 kW, and you can go with 110 V up to 600 V, so its engine fits your outré source.

Call to Action:

Want to boost quality with a vacuum mixing tank? Reach out for details, get a fast quote, or lock in your order; our team is eager to back you every step.