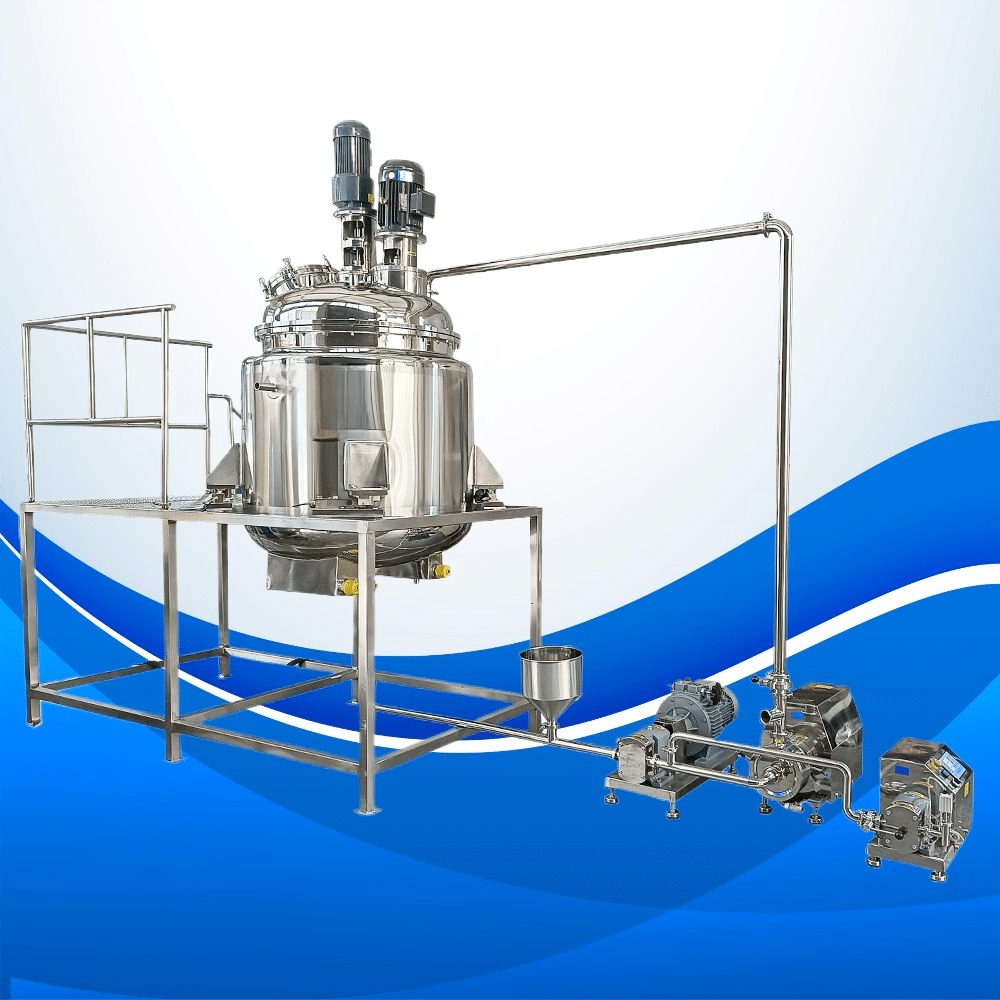

Introduction: Why You Need a Chemical Mixing Machine

In today’s fast-paced production world, getting a uniform, top-notch mix every time is a must. A chemical mixing machine gives you the accuracy and speed you need in fields like pharma, food, cosmetics, and chemical manufacturing. Whether you’re ramping up a new line or fine-tuning what you’ve already got, the right mixer lets you make more product faster and spend less doing it.

Key Features and Specs

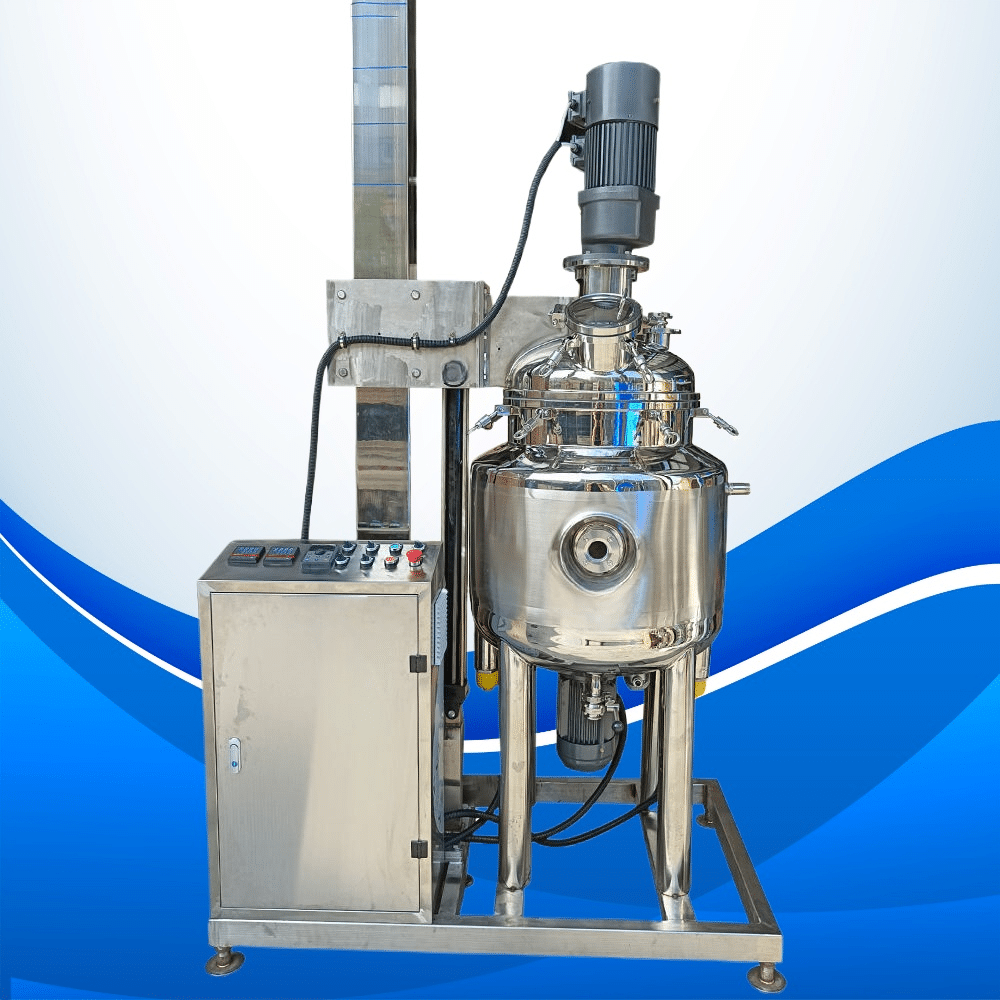

Our chemical mixing machine is built to handle the toughest industrial demands without breaking a sweat. Tough enough to last and flexible enough to fit different jobs, it has features you can tweak to match your process.

Material Choices

Premium stainless steel in 304 or 316L, giving you great corrosion resistance and keeping it clean.

Motor Power

Options from 1.5KW to 11KW, so you can match it to how thick or watery your mix is.

Capacity Range

Choose from 50 liters up to 30,000 liters, perfect for everything from a small test batch to a full production run.

Mixing Action

Precision-made agitators that deliver a consistent mix, whether you’re blending liquids, powders, or thick pastes.

Maintenance Made Easy

Smooth surfaces and a CIP (Clean-in-Place) setup cut cleaning time and keep your machine running.

Safety First

Meets all the global safety and quality standards you expect.

Put these features together, and you’ve got a mixing machine that’s flexible, reliable, and ready for whatever your industry throws at it.

Applications in Real-World Industries

Picture a drug plant where solvents and actives merge without a hitch, or a cosmetics line where emulsions turn out flawless every time. Our blending units are already in service at:

- Pharma: Sterile blending of actives and solvents, no contaminants.

- Food & Beverage: Flavors, syrups, and additives mixed with cleanliness as priority.

- Cosmetics: Lotions, creams, and serums with textures that match every batch.

- Chemical Production: Resins, adhesives, and specialty compounds coming together.

- Water Treatment: Chemical solutions get ready for purification.

Adding our gear to your setup means same-results consistency, fewer human mistakes, and a smooth path to scale without the bumps.

Material Choices: 304 vs. 316L Stainless Steel

Picking the right metal for your blender comes down to what you are processing:

- 304 Stainless Steel: Tough and ready for everyday stuff, non-corrosives are no problem.

- 316L Stainless Steel: Extra brave against strong chemicals and saltwater—ideal for pharma labs and coastal sites.

Both choices keep the structure strong and meet the most demanding hygiene checks.

Customization: Power and Size

Every production line has its quirks, so we let you build what you need:

Power Choices

Start at 1.5KW for light blending, kick up to 11KW for really thick stuff.

Capacities

Need a tight 50L mixer for lab tests or a giant 30,000L setup for full-scale production? We can tweak the design to match whatever size you need.

This means you can dial in the perfect fit for your process without wasting money on extras or short-changing yourself.

Why Our Chemical Mixing Machine?

We’re all about quality, precision, and keeping you supported after the sale. After years in the industrial mixing game, we offer:

- ✅ Custom designs that match your exact process

- ✅ First-class craftsmanship and the best materials

- ✅ Ongoing support and ready access to spare parts

- ✅ Worldwide shipping and installation help

When you pick our chemical mixer, you’re choosing a machine that delivers reliability, efficiency, and real long-term savings.

Get Started + Common Questions

Want to boost your mixing game?

Hit us up now for a free chat, and we’ll whip up a quote that fits your production plan.

FAQs

Q1: Can the machine handle thick materials?

Definitely. With motors that go up to 11KW, our mixers can power through both thin and thick stuff without a hitch.

Q2: Can I use the machine in food production?

For sure. Our 304 and 316L stainless steel versions meet all hygiene rules in food and drink manufacturing.

Q3: Do you help with installation?

Totally! We ship worldwide and can have a pro install it for you.

Q4: How long does it take to get my order?

Usually, it takes about 4 to 8 weeks, but if you want a lot of custom stuff, it might take a bit longer.