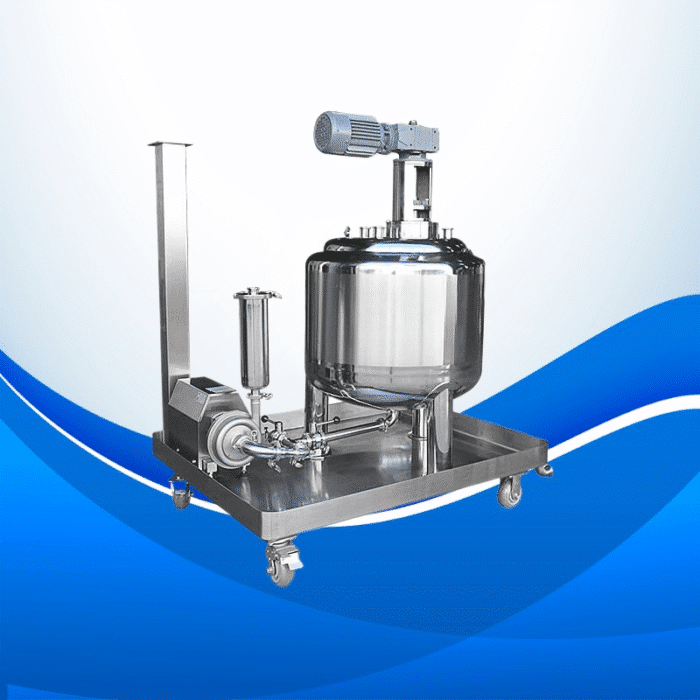

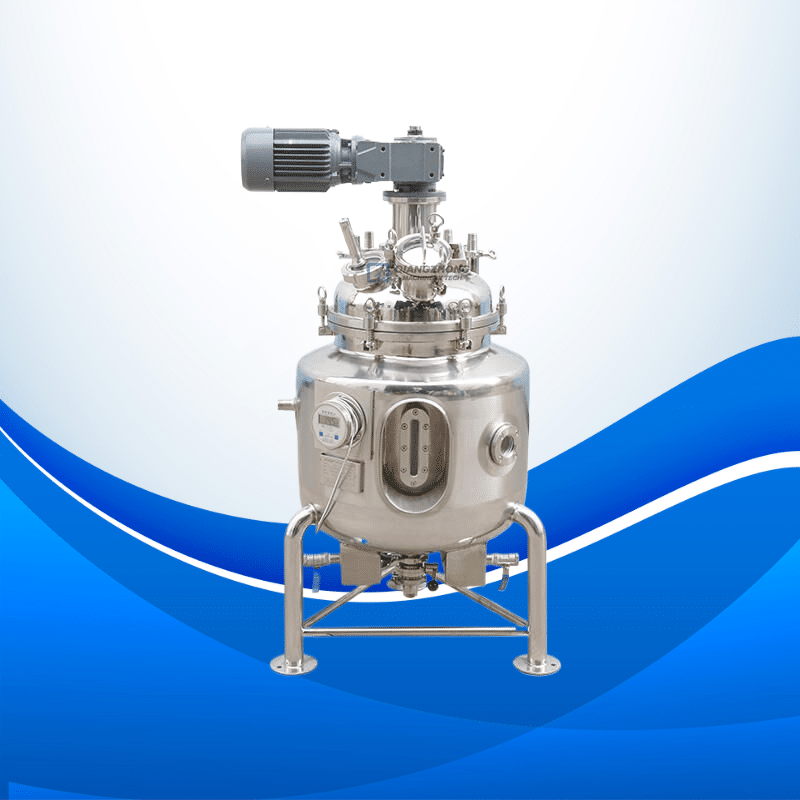

High-Performance Perfume Mixing Machine

- Capacity: 50 liters to 30,000 liters

- Mixer power: 1.5 kW to 55 kW

- Material: 304 or 316L

- Voltage: 110V to 600V

- Heating method: Electric or steam heating

- Layer:single/double jacket/three jacket

- Mixer types: Impeller-type, Anchor-type, Turbine-type, High-shear-type, Magnetic mixer, Anchor-type mixer with scrapers,dispersing

- Optional: platform, wheels, ladder,variable frequency drive,explosion-proof device

- Certificates: ASME, CE, GMP, UL, ATEX, ISO 9001

- Our equipment supports customisation, global delivery, and a 1-year warranty.

- If you have drawings, we can process them for you.

Note: Please contact our sales team before placing an order. Website prices are for reference only; specific pricing requires understanding your requirements to provide a quote.

Email:info@ace-chn.com

Tel: +86 186 2683 5909

WeChat: ace-chn

WhatsApp: +86 186 2683 5909

$3,410.00

Guaranteed Safe Checkout

Recommend RPM: 0-960RPM

Viscosity: Low/medium viscosity

Application: Mainly Liquid mixing

Recommend RPM: 0-200RPM

Viscosity: Low/medium viscosity

Application: Mainly Liquid mixing

Recommend RPM: 30RPM

Viscosity: Medium/High viscosity

Application: Melting, High viscosity product mixing, For single wall tank

Recommend RPM: 30RPM

Viscosity: Medium/High viscosity

Application: Melting, High viscosity product mixing, For jacket tank

Recommend RPM: 1480/2850 RPM

Viscosity: Low/medium viscosity

Application: Liquid powder mixing and dispersion

Recommend RPM: 1480/2850 RPM

Viscosity: Low/medium/High viscosity

Application: Liquid powder mixing and homogenizing

Recommend RPM: 0-355RPM

Viscosity: Low/medium viscosity

Application: Install at bottom, No mechanical seal working condition

Recommend RPM: As above

Viscosity: Low/medium viscosity

Application: Liquid powder mixing and dispersion For tank volume >300L

Perfect Perfume Mixing—Speed and Precision Together

If you’re making special small-batch scents or running big perfume lines, you need a mixer you can trust to keep every bottle smelling just right. Our next-gen machines are built to keep pace with every kind of perfume-making. They’re fast, flexible, and ready for years of use without missing a beat.

What You Get & How You Can Change It

Material Choices:

Pick either 304 or 316L stainless steel. 304 is great for most scents, while 316L is for things that need extra care. Both types resist rust and keep your notes pure.

Size to Fit:

We make from 50L bench-top machines for small studios right up to 30,000L tanks for factory floors. So, whether you dream of a single signature spray or a whole batch of store-ready lines, we have your size.

Power to Mix:

You can choose motors from 1.5KW for gentle swirls to 11KW for heavy creams. Our speed controllers let you dial in just the right pace to break up oils or fold in bases without leaving swirls behind.

Where It Works & Why You’ll Love It

In real life, our mixer shines in every setting:

- High-end perfume labs use it to balance top notes and base notes with cosmetic-grade accuracy.

- Cosmetic plants are the best spot for dropping fragrance right into lotions, creams, and body mists.

- Contract production places can blend big batches of perfume and keep the same great smell every time.

- R&D teams can run smaller machines to play with new smells before going big.

Every machine we make speeds up the fragrance game. You get faster results, less waste, and the same scent bottle to bottle.

Built to Work Hard

Our machines come with easy-to-use controls, strong frames, and clean-out features so you can get back to work fast. They blend water and oil phases, so they fit right into any recipe. You can also add jacketed tanks for heating and cooling, or special paddles, to dial in your production line even more.

Why Pick Our Mixer?

You can tweak it to your exact formula. The design is clean and meets GMP. The motors save energy, and the frames last, giving you great return on investment. Plus, we offer on-the-ground support wherever you are.

FAQs

Q: What’s the difference between 304 and 316L stainless steel?

A: Both are tough, but 316L fights rust even better, making it great for salty or acidic mixes.

Q: Can I mix emulsions and alcohol-based perfumes with this machine?

A: For sure. This mixer handles both emulsions and alcohol perfumes while keeping everything balanced and on point.

Q: What’s the maintenance routine like?

A: Just clean it regularly and give it a quick check. The stainless-steel surface keeps grime away, and the parts pop out easily when you need to reach them.

Ready to Boost Your Perfume Game?

Whether you’re growing your lineup or want every batch to smell exactly the same, our perfume mixer delivers the toughness and flexibility you need. Pick your size, power, and materials, and you’ve got a smart upgrade for any fragrance maker.

Hit us up for a quote and start your journey to faster, consistent, and better scent production.