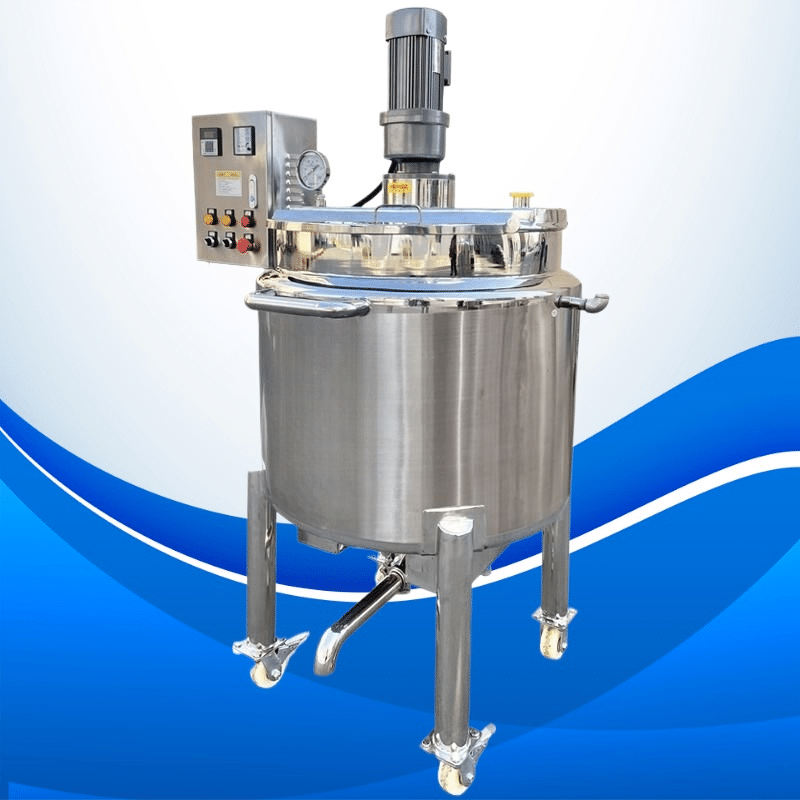

Product Description: Heating Mixing Tank

The Heating Mixing Tank is the workhorse you want when your job calls for even heat and steady mixing. Built tough, it links quick warm-up coils with a gentle stir so everything flows right, whether you’re making drinks, chemicals, medicine, or lotion.

Key Features & Benefits

All-in-One Heat & Mix

Its smart design gives a steady temp and smooth blend, no matter if you pour in water, thick paste, or semi-stiff gel.

Custom Fit

Pick the voltage (from 110V to 600V) and power (1.5KW to 55KW) that match your setup, letting labs scale up or factories run nonstop trouble-free.

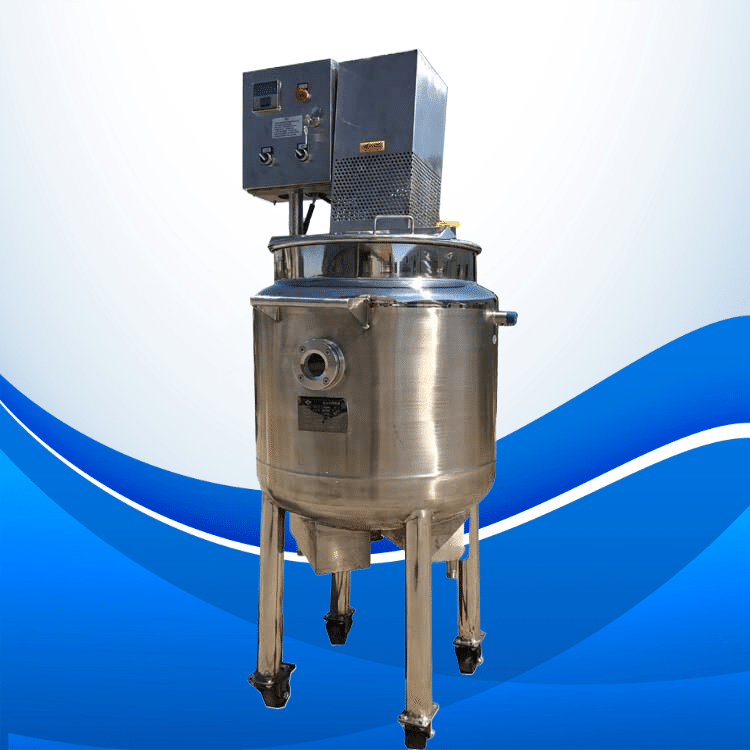

Strong Materials

Made of 316L or 304 stainless steel, it laughs off rust and bumps, guarding your batch quality for years in food and pharma lines.

Green & Cost-Savvy

High-efficiency heaters cut power bills and emissions while still delivering the same rock-solid results you expect.

Easy Operation

The tank comes with simple buttons and dials, so you can change the temperature or the mixing speed quickly. Whether you want a slow stir or a fast whip, you set it exactly how the job needs.

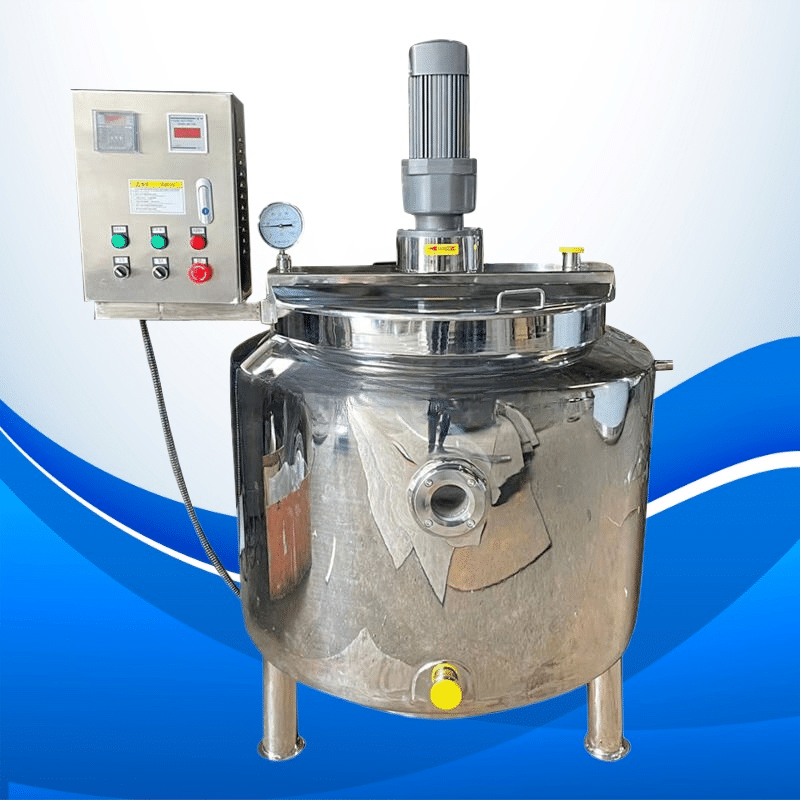

Temperature Control & Safety

A smart heating system tracks the mix’s heat, keeping it where you set it and stopping it from going too high. That extra care matters when you’re working with fragile recipes that could spoil in harsh heat.

Applications and Real-World Use Cases

The Heating Mixing Tank is a dependable partner in many shops, keeping tasks quick, smooth, and friendly to the budget:

Food & Beverage

Chefs and bottlers use it for sauces, syrups, and ready meals. Because the heat stays even, and the stirrer moves all around, every batch tastes just the same.

Cosmetics & Pharmaceuticals

Makers of creams, gels, and tablets count on the tank to guard fragile powders and beauty oils, giving each mix the gentle warmth it needs.

Chemical & Industrial Manufacturing

Factories blend thick pastes, soaps, or cleaners in the unit, freeing up the line and cutting the chance that quality slips during heating or mixing.

Technical Specifications

Voltage Options

Choose 110V, 220V, 380V, 440V, or even 600V to match any outlet around the planet.

Power Options

Scale up from quiet 1.5KW stations to beefy 55KW setups for high-output plants without losing efficiency.

Material Options

Pick 316L stainless steel if you need top-notch rust protection, or go with 304 stainless steel for everyday jobs. Either way, both grades pass strict tests for strength and cleanliness.

Mixing Speed

Turn a dial to set the stir rate just right, whether the liquid is thin like water or thick like batter.

Temperature Range

Heat the tank from room temp up to 200°C or even more, so you’re ready for the job at hand.

Why Choose Our Heating Mixing Tank?

Superior Quality

Built with first-class stainless steel, the unit stands up to bumps, spills, and steam for years on the floor.

Customizable

Tell us the voltage, power, and finish you want, and we’ll build a tank that fits your shop.

Energy Efficient

Smart insulation and a steady heater mean lower watt-hours, trimming your monthly bill without cutting performance.

Versatile

From sauces in a kitchen to powders in a lab, the tank works in food, chemicals, or pharma, making it hard not to use.

Call to Action: Order or Customize Your Heating Mixing Tank Today!

Want to make your mixing and heating work faster and smoother? Whether you’re running tests in a small lab or pushing out batches in a big factory, we can build a tank that’s just right for you. Reach out now for a quick chat or start designing your own unit!

Frequently Asked Questions (FAQ)

What industries can benefit from a heating mixing tank?

Food makers, skincare brands, drug companies, chemical plants, and lots of other fields rely on our tanks because they heat and stir material evenly, day in and day out.

Can I customize the voltage and power of the heating mixing tank?

Absolutely! Choose from 110V to 600V, and pick a power level from 1.5KW to 55KW, so the tank fits your outlets and production speed.

Which material is best for my application?

316L stainless steel is the go-to for anything corrosive or food-related, while 304 steel works fine for most general factory jobs. Not sure? Just ask our team, and we’ll point you in the right direction.