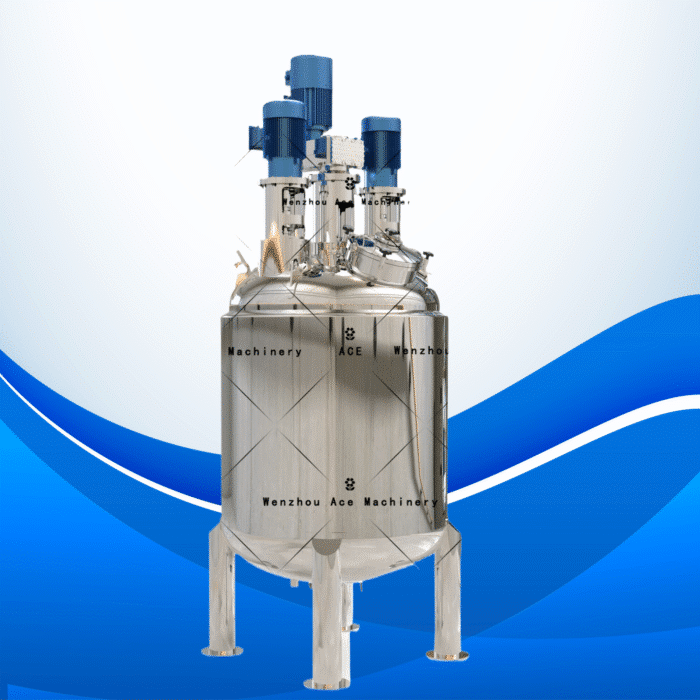

Liquid Fertilizer Mixing Tank

- Capacity: 50 liters to 30,000 liters

- Mixer power: 1.5 kW to 55 kW

- Material: 304 or 316L

- Voltage: 110V to 600V

- Heating method: Electric or steam heating

- Layer:single/double jacket/three jacket

- Mixer types: Impeller-type, Anchor-type, Turbine-type, High-shear-type, Magnetic mixer, Anchor-type mixer with scrapers,dispersing

- Optional: platform, wheels, ladder,variable frequency drive,explosion-proof device

- Certificates: ASME, CE, GMP, UL, ATEX, ISO 9001

- Our equipment supports customisation, global delivery, and a 1-year warranty.

- If you have drawings, we can process them for you.

Note: Please contact our sales team before placing an order. Website prices are for reference only; specific pricing requires understanding your requirements to provide a quote.

Email:info@ace-chn.com

Tel: +86 186 2683 5909

WeChat: ace-chn

WhatsApp: +86 186 2683 5909

$4,100.00

Guaranteed Safe Checkout

Recommend RPM: 0-960RPM

Viscosity: Low/medium viscosity

Application: Mainly Liquid mixing

Recommend RPM: 0-200RPM

Viscosity: Low/medium viscosity

Application: Mainly Liquid mixing

Recommend RPM: 30RPM

Viscosity: Medium/High viscosity

Application: Melting, High viscosity product mixing, For single wall tank

Recommend RPM: 30RPM

Viscosity: Medium/High viscosity

Application: Melting, High viscosity product mixing, For jacket tank

Recommend RPM: 1480/2850 RPM

Viscosity: Low/medium viscosity

Application: Liquid powder mixing and dispersion

Recommend RPM: 1480/2850 RPM

Viscosity: Low/medium/High viscosity

Application: Liquid powder mixing and homogenizing

Recommend RPM: 0-355RPM

Viscosity: Low/medium viscosity

Application: Install at bottom, No mechanical seal working condition

Recommend RPM: As above

Viscosity: Low/medium viscosity

Application: Liquid powder mixing and dispersion For tank volume >300L

Liquid Fertilizer Mixing Tank: Changing the Game on the Farm

The liquid fertilizer mixing tank is quickly becoming a must-have for growers who want to mix fertilizer faster and more reliably. Built for big farms, busy greenhouses, or companies that sell fertilizer, this tank makes sure every drop of fertilizer is blended the same way, so crops get the right nutrients and yields climb higher.

Key Features and Benefits:

Better Mixing Every Time

With smart mixing tech inside, the tank spins and swirls liquids until everything is perfectly together. That even blend means plants soak up more food, making the fertilizer work harder and saving money in the long run.

Power That Fits Your Shop

Rated for voltages from 110V home circuits to the heavy 600V feeds big factories use, the tank slides right into your setup. Choose from motors between 1.5KW for small runs and 55KW for full-scale lines, so you only pay for the push you really need.

High-Quality Materials

You can pick either 316L or 304 stainless steel for the mixing tank. Both grades resist rust, so the tank won’t quickly break down when exposed to the tough chemicals usually around fertilizers. Choose 316L if your mix includes extra-aggressive ingredients; 304 is perfect for ‘standard’ jobs and holds up really well.

Durable and Long-lasting

Built with extra-strength parts, this tank is made to keep working for years and asks for very little care. The rust-proof metal and heavy-duty frame can take on rugged farm conditions, so you won’t need to swap out tanks often and can count on a solid return on what you spend.

Ease of Use and Maintenance

Operating the tank is simple because the controls are laid out in a clear way, letting you mix fertilizer quickly and reliably. Clean-up is also quick, which stops one batch from accidentally contaminating the next.

Applications and Use Cases:

The liquid fertilizer mixing tank works well in plenty of farming situations, including:

Farm Operations

Whether crops are grown in a field or a greenhouse, the tank makes the right nutrient blend. A spot-on mix keeps soil healthy and helps plants grow strong, leading to better yields and quality.

Commercial Fertilizer Production

Fertilizer makers and dealers blend big batches in these tanks. Because they come in different sizes and power setups, the units fit small farms or large factories, adding flexibility to the work.

Hydroponic and Aquaponic Systems

In soil-free systems, keeping nutrients on-target is crucial. The mixing tank blends water-soluble formulas evenly, so plants thrive without the trouble of too much or too little feed.

Organic Farming

Organic growers who need a custom fertilizer recipe use the tank to mix liquid compost and other blends. Sturdy construction lets the tank handle both natural and synthetic products without issues.

Research and Development

Labs and test-greenhouses turn to our liquid-fertilizer mixing tanks whenever they need spot-on blends for plant-growth experiments. Reliable accuracy means researchers can trust their data.

Specifications and Options:

Voltage

Pick any voltage between 110V and 600V, so the unit works smoothly in your space, from a small backyard plot to an industrial nursery.

Power Options

With motors rated from 1.5KW to 55KW, the tank can stir anything from a few liters to several thousand, matching the scale of your project.

Material Choices

Go with 316L stainless steel for harsh, salty mixes, or stick with 304 stainless when standard fertilizers are all you handle; both resist rust and are easy to clean.

Why Choose Our Liquid Fertilizer Mixing Tank?

Customizable Options

Voltages, horsepower, and parts material can be swapped before shipping, so the machine fits your farm, lab, or greenhouse perfectly.

Efficient and Precise

Even blending cuts waste, boosts crop health, and typically lifts yields, making every batch worth its time and expense.

Built-To-Last Design

Because we use heavy-duty materials and smart engineering, this mixing tank stands up to years of tough use in hot, cold, or chemical-rich places—and that means you’ll keep saving money instead of replacing equipment.

Flexible Use Options

Whether you run a backyard hobby farm or a big commercial greenhouse, the tank fits your setup and can be worked by hand or hooked up to an automated line so everyone on the team stays productive.

Act Now and Get Your Custom Tank

Click or call to lock in your tank, pick the upgrades you need, and watch your fields thrive as every drop of fertilizer gets blended perfectly.

Frequently Asked Questions (FAQ):

Is there a warranty on the liquid fertilizer mixing tank?

Sure thing, every one of our mixing tanks is backed by a warranty that protects you against factory faults and makes sure the unit runs smoothly for years.

Can I customize the tank based on my specific needs?

Definitely! You can tweak things like power source, voltage, and even the tank material. Reach out to us, and we’ll walk you through the custom order options.

What maintenance is required for the tank?

Our tank needs very little upkeep. A good cleaning now and then plus a quick look at the seals is usually all it takes. You’ll find a handy manual inside that spells out every step.