High-Shear Mixing Tank: Upgrade Your Industrial Mixing with Reliable Precision

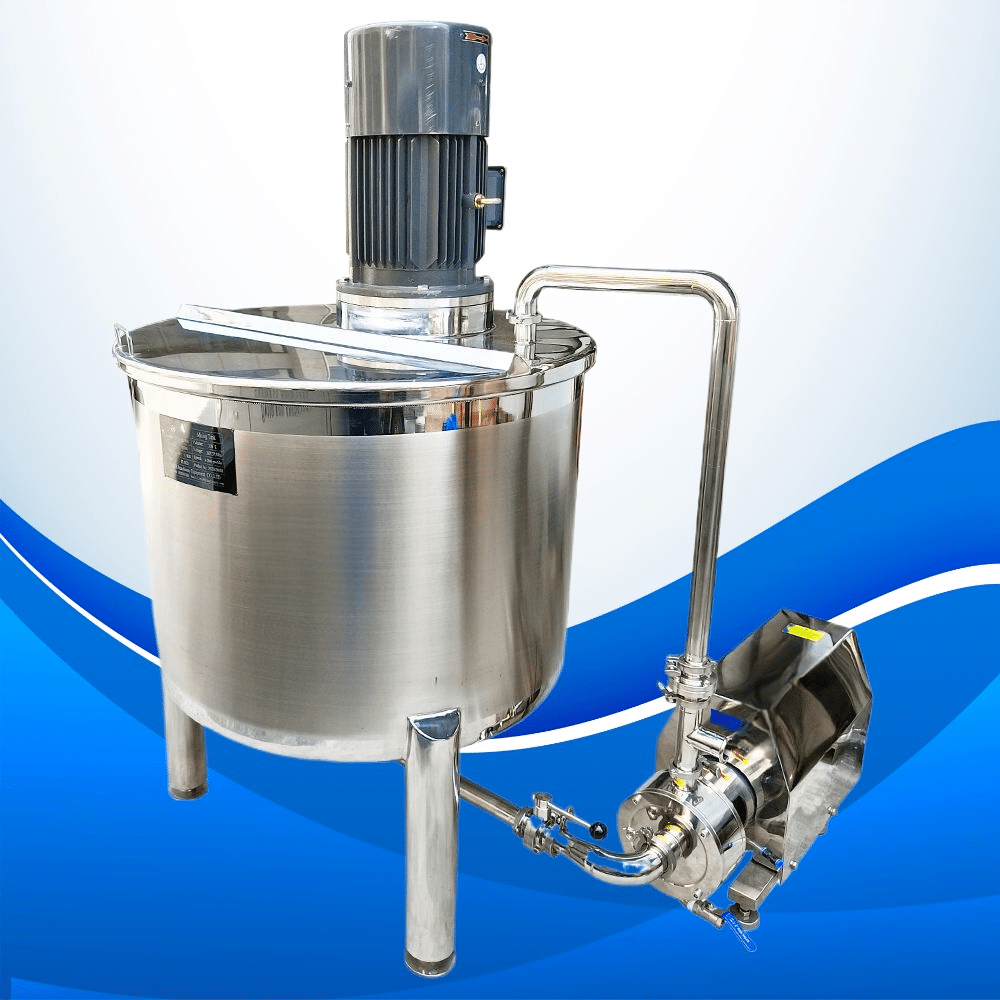

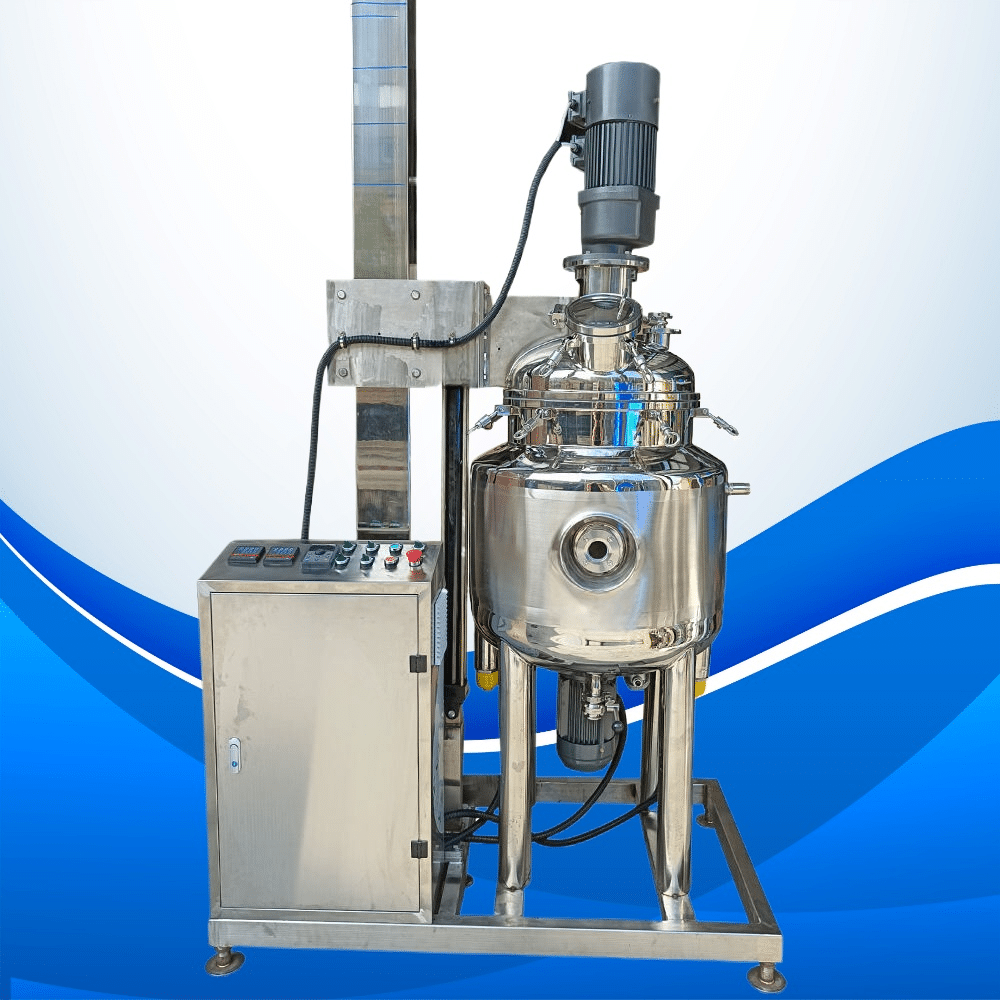

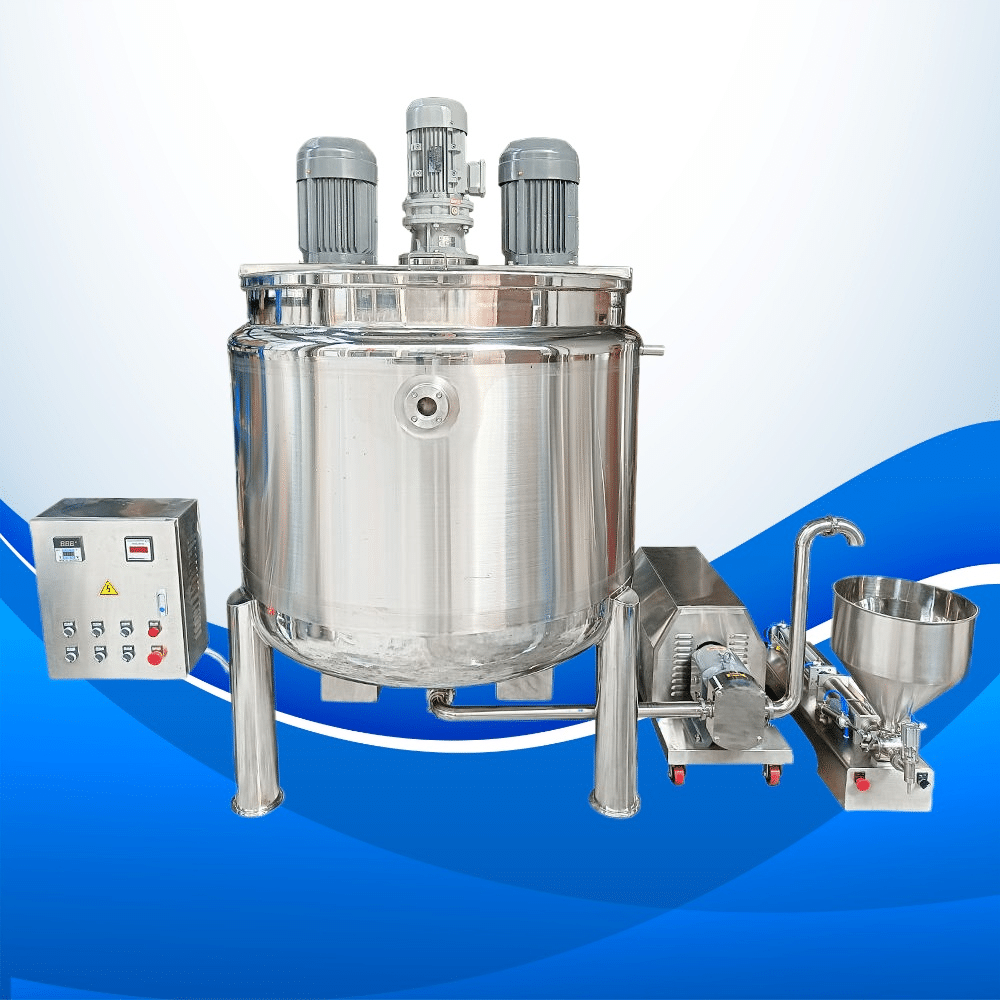

When you run a factory, keeping every batch the same can make or break your product quality. A high-shear mixing tank was made with that problem in mind. From sauces and lotions to pills and creams, this heavy-duty unit mixes, blends, and breaks down tough ingredients so you get smooth, even results every time. Because it can work with thin liquids, thick gels, or even sticky pastes, it takes the guesswork out of mixing.

Speed Matters

Whether you run a small line or a big plant, minutes lost at the mixer add up and hurt your bottom line. A high-shear unit finishes batches faster while using less energy than older paddle-type mixers. In the rest of this overview well detail how the tank is built, the options you can add, and real-world cases that show how customers like you are seeing better products and lower waste.

Key Features and Benefits of a High-Shear Mixing Tank

1. Efficient Mixing and Homogenization

The heart of the tank is its rotor-stator head spinning at up to 5000 rpm. At that speed, roiling liquid hits dozens of sharp edges and small gaps every second, breaking up lumps, trapping air, and spreading oil into water. The result is an ultra-smooth blend with a shelf life that can double. People who used slower mixers say they’ve never seen texture this even, and quality reports back them up.

2. Where You’ll See This Mixing Tech

You’ll find this high-shear mixer in places that can’t afford even a small slip in quality. It’s the go-to tool in:

- Food and Drink: Whether you’re whipping up a spicy sauce, a smooth shake, or creamy yogurt, it keeps every drop equally tasty.

- Pharma: In hospitals and drugstores worldwide, it helps blend ointments and liquid meds, so every batch works the same way.

- Beauty and Body Care: From sunscreens to hair conditioners, the mixer nails the creamy feel and prevents lumpy surprises on the shelf.

- Chemicals: Painters, builders, and carmakers rely on it to stir pigments, glues, and tough coats evenly, speeding up the entire production line.

3. Power and Voltage Just for You

Our tank isn’t a one-size-fits-all; It’s designed to match your plants’ energy setup. Choose motor levels between 1.5 kW for small runs and 55 kW for heavy loads, so you never waste power or time. Then pick a voltage-from house-friendly 110 V all the way up to 600 V-ready for outlets found anywhere on the globe.

4. Material Choices for Better Corrosion Resistance

Which stainless steel you pick-316L or 304-depends on what you make. Because 316L fights rust way better, it shines in harsh chemicals, food lines, and pharma work. 304 costs less and handles easy mixing jobs in gentler settings just fine.

5. Simple, User-Friendly Design

Every high-shear tank is built to be easy to use, clean, and fix. A sturdy frame cuts down wear, and a clear control panel lets workers tweak speed, power, and blend strength. With quick-clean parts and sealed motors, these tanks switch from one batch to the next in record time.

Applications in Various Industries

Food and Beverage Industry

In food plants, high-shear tanks mix oil, water, and emulsifiers into dressings, sauces, and drinks. They make every batch silky and uniform, so goods stay fresh on store shelves. From light blends to ultra-fine emulsions, the tank serves up accurate, repeatable results every single time.

Pharmaceutical and Cosmetics Manufacturing

Pharmacies and skincare brands need every batch of creams, gels, and lotions to feel, smell, and work the same way- because a tiny mistake can hurt customers. Our high-shear mixing tank spins the ingredients at lightning speed, so every active dose ends up in the right spot. For makeup makers, that same force whips shampoo, lotion, and foundation to the silky, glossy finish shoppers expect.

Chemical and Adhesive Production

Paints, sealants, and strong glues rely on tiny, evenly spread particles to bond, cover, and last through time. In the chemical plant, a high-shear tank pulls stubborn pastes and heavy pigments into a smooth ribbon, leaving no lumps behind. Rich dispersion of additives and resins lifts performance and gives quality controllers the confidence every drum will meet the standard.

Power Options and Technical Specifications

- Power Options: Ramp up from 1.5 kW for pilot batches to 55 kW for full plants.

- Voltage Options: Choose 110 V, 220 V, 380 V, or 600 V, so set-up plugs right in.

- Materials: Go with 316L stainless for heavy-clean or 304 stainless for most jobs.

- Mixing Capacity: Pick tank size and layout that fits your floor and output plans.

Why Choose Our High Shear Mixing Tank?

- Precision and Efficiency: Save power without sacrificing the twin goals of even mix and repeatable result.

- Wide Customization: Pair the right motor, voltage, and steel grade for your process, your team, and your local code.

- Durability: Every mixing tank is made from strong, anti-rust materials and put together in a way that stands up to hard daily use.

- Ease of Use: Simple buttons and a design that needs little upkeep keep your tank running at its best and keep downtime to a minimum.

Ready to Boost Your Production

Buying a high-shear mixing tank is a smart move that pays you back with faster output, better product quality, and a calmer workday. Whether you need a lab-sized model or a beast for the factory floor, we can tweak the set-up so it fits just right. Get in touch, tell us what you need, and well build the perfect tank that helps your business grow.

FAQs

1. What materials are the high-shear mixing tanks made of?

Our tanks come in two main choices-316L stainless steel for corrosive products or food-pharma work, and 304 stainless steel for most other jobs.

2. What is the maximum power available for a high-shear mixing tank?

Tanks are offered in power ratings from 1.5 kW up to 55 kW, giving you options for any production size.

3. Can I customize the voltage?

Absolutely! We fit high-shear tanks to voltages between 110 V and 600 V, so they work at home or anywhere around the world.

4. Is the high-shear mixing tank easy to clean and keep running?

Absolutely! It has smooth surfaces and few nooks, so you can wipe it down fast between batches without much fuss.

5. How do I pick the right size and power for my setup?

Contact us with your production goals, and we’ll match you with the tank specs that meet your needs best.