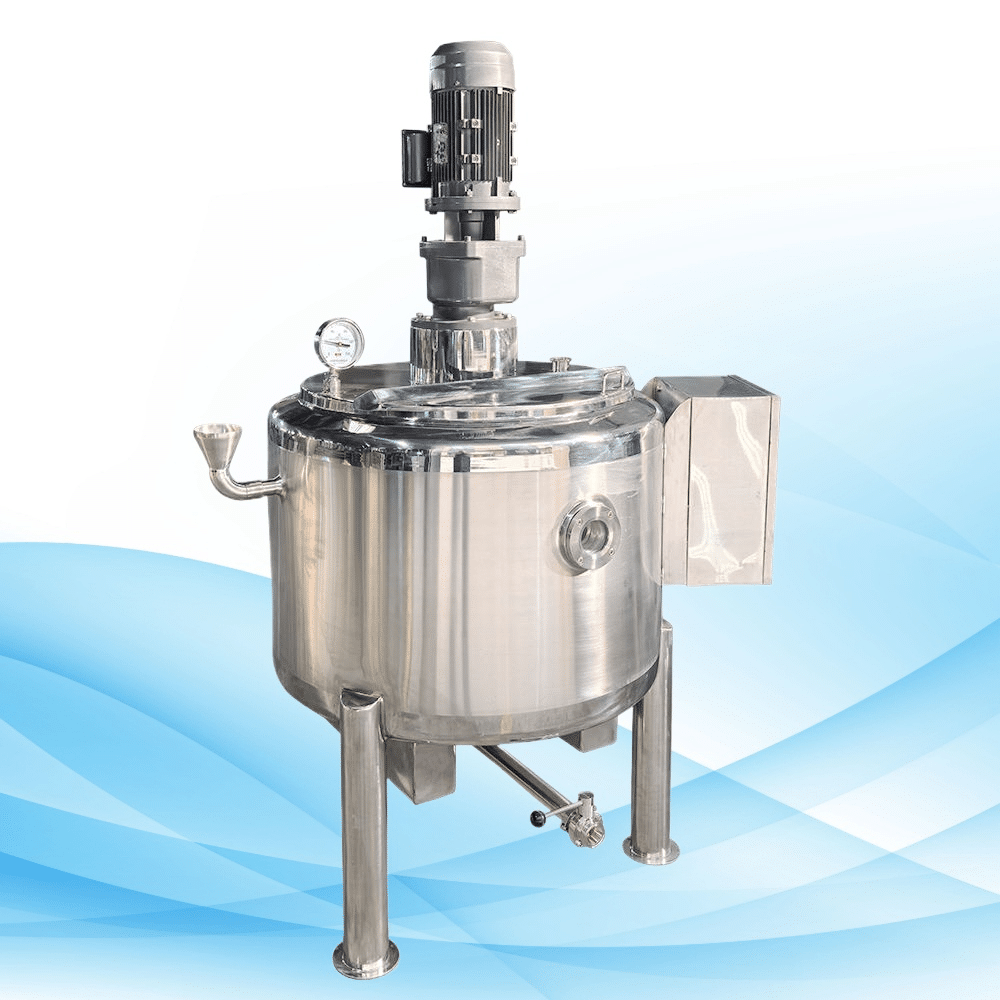

Product Description: Heat Jacketed Mixing Tank

A heat-jacketed mixing tank is a key piece of equipment for any plant that needs to heat and stir product at the same time. From thin liquids to thicker slurries and semi-solids, the tank creates the steady, warm zone that lets raw materials blend quickly and evenly. Because the temperature stays on target while the mixer runs, these units are crucial in food, pharma, chemical, and cosmetics operations.

Key Features of Heat-Jacketed Mixing Tank:

- Heating Jacket: A wrap-around heating jacket delivers warm water or oil around the shell, spreading heat from top to bottom. That even warmth helps delicate recipes reach the right temp without scorches or cold spots.

- Precise Temperature Control: Built-in sensors keep watch on the batch, so operators can dial in the exact set-point and the digital controller adjusts the jacket as needed.

- Durability & Corrosion Resistance: Tanks made of heavy 316L and 304 stainless steel resist rust, pitting, and long cleaning shifts, giving years of reliable service in hygienic or harsh chemical lines.

- Customizable Size & Power Options: Ranging from 1.5 kW to 55 kW and with voltages from 110V to 600V, every tank can be tuned to your application and work space.

- Versatile Applications: Emulsification, mixing, blending, heating-each unit does it all, which is why businesses in so many fields keep them on hand.

Applications of Heat-Jacketed Mixing Tanks

Food and Beverage Industry

In food manufacturing, the tank blends ingredients and holds them at a set temperature. During sauce, jam, or dairy production, even heat and even shear protect flavor and texture. The jacketed design stops hotspots that would otherwise burn or scorch the batch.

Pharmaceutical Industry

Precision defines the pharmaceutical sector, and a jacketed tank delivers it. Heat-sensitive powders and liquids are evenly heated without losing active ingredients. Whether the end product is an ointment, cream, or syrup, the controlled climate guards quality from start to finish.

Chemical Manufacturing

In many chemical processes, consistent temperature can mean the difference between success and failure. Heat-jacketed mixing tanks let operators stir chemicals while gently adding or removing heat, helping to avoid runaway reactions or product spoilage.

Cosmetic Industry

Personal-care products need careful blending of oils, waxes, emulsifiers, and actives. By heating and whisking these ingredients in a jacketed tank, manufacturers keep the emulsion smooth, stable, and exactly as the formula demands.

Technical Specifications

- Material Options: 316L stainless steel withstands harsh cleaners and is the go-to for food and pharmaceutical work. 304 stainless is more budget-friendly and fine for many general mixing jobs.

- Voltage Options: 110 V suits small labs or countries that use lower mains. 220 V is the standard for most mid-sized factories. 600 V works in bigger plants that need a heavy power feed.

- Power Options: Ratings from 1.5 kW to 55 kW let buyers pick the heating and mixing speed they need. High-power models cut wait times when processing large batches.

- Size Options: Heat-jacketed mixing tanks are available in a wide range, from compact 100-liter units for small batches to massive installations that hold thousands of liters. If standard sizes don’t fit your process, we can build a custom tank to your exact specifications.

Why Choose Our Heat-Jacketed Mixing Tanks?

- Efficiency and Cost Savings: The jacket delivers rapid, even heating, so you spend less on energy without sacrificing mixing speed. Over time, this boost in efficiency translates into noticeable savings on both utility bills and equipment wear.

- Customizable for Your Needs: Process conditions vary, and cookie-cutter equipment often falls short. To solve that, we give you options for tank size, heating power, and even surface finish, so the equipment works in harmony with your production line.

- Enhanced Durability: Crafted from premium stainless steel, our tanks stand up to steam, cleaning chemicals, and the rigors of continuous use, giving you a reliable asset that keeps producing for years without costly corrosion repairs.

- Precise Temperature Control: An integrated controller enables in-line monitoring and adjustment of the jacket temperature, helping you maintain the precise heat window that drives consistent product quality from batch to batch.

- Easy Integration into Your Production Line: Compact footprints, forklift slots, and standardized connections make installation straightforward, limiting downtime and letting you start benefiting from improved heating and mixing within a matter of shifts.

Order Your Heat-Jacketed Mixing Tank Today!

Looking for a dependable, made-to-order tank that heats and mixes at the same time? Our heat-jacketed mixing tanks fit the bill, no matter whether you’re based in food processing, pharmaceuticals, chemicals, or cosmetics. With robust engineering and flexible options, they take the guesswork out of temperature-sensitive batches. Stop settling for off-the-shelf units; order your bespoke heat-jacketed mixing tank today.

Need something specific? Contact us for custom orders!

Frequently Asked Questions

1. What is the maximum temperature that can be reached in a heat-jacketed mixing tank?

Most heat-jacketed mixing tanks can reach temperatures up to 200°C (392°F), but this can vary depending on the material of construction and the heating system used.

2. Can the tanks be used for mixing viscous materials?

Yes, our heat-jacketed mixing tanks are designed to handle both low and high-viscosity materials. For particularly thick substances, additional mixing mechanisms can be added.

3. Are these tanks suitable for food-grade applications?

Absolutely. Tanks made from 316L stainless steel are ideal for food-grade applications due to their superior corrosion resistance and ease of cleaning.

4. What warranty is included with the heat-jacketed mixing tank?

Every heat-jacketed mixing tank is backed by a one-year standard warranty. If you want extra peace of mind, you can ask about extended warranty options.

5. How do I figure out the right power and size for my needs?

Our team will walk you through the process and recommend the tank size and power level that fit your operation. Just reach out for a free, no-obligation consultation.