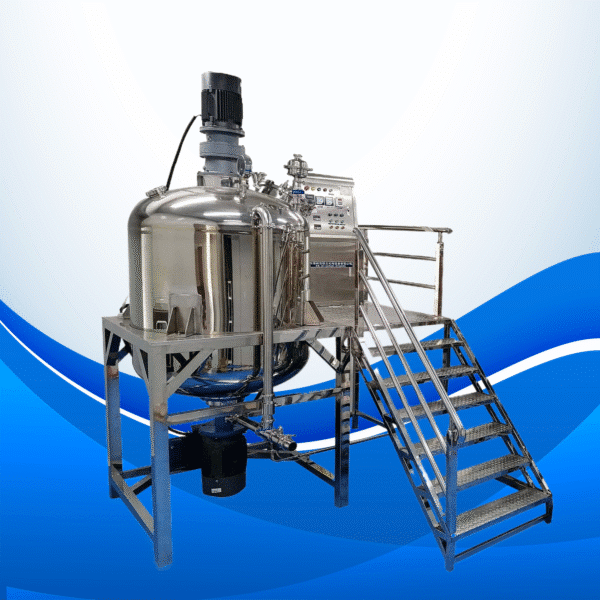

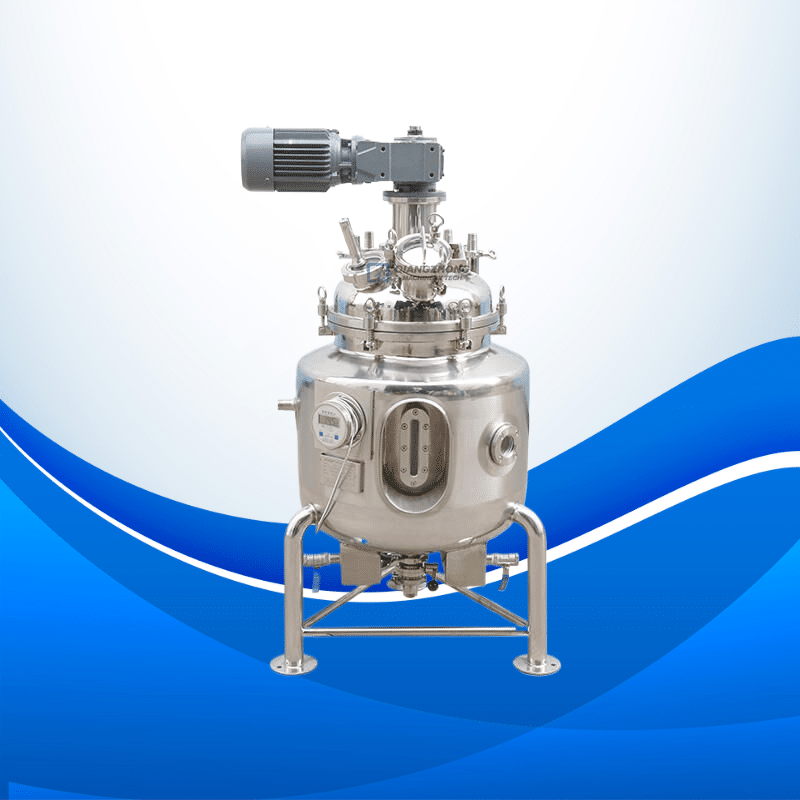

Milk Mixing Tank: A Game Changer for Dairy Operations

In today’s fast-moving dairy market, having dependable gear can make or break a production line, and the milk mixing tank is no exception. Whether it’s fortifying the drink with vitamins, adding a hint of chocolate, or preparing a creamy base for ice cream, this tank blends everything evenly, so the final product tastes the same from the first glass to the last. From family-run dairies to large bottling plants, choosing a good mixing tank not only lifts product quality but also speeds up the whole operation.

Top Benefits You’ll Notice Right Away

Better Mixing with Less Sweat

Over-engineering stirs up more problems than milk, which is why these tanks come with precision blades tuned for dairy. Their gentle but thorough action pulls liquid from the top, sides, and bottom, leaving no pocket of cream or additive untouched. That matters when you move from berry yogurt to plain milk; one quick clean, a new recipe, and you know the mix will come out uniform every single time.

Made-to-Order Features:

Our milk mixing tanks come in different setups so they work just right for your business. You can pick a voltage between 110V and 600V and power levels from 1.5KW to 55KW, making sure the tank plugs into what you already have and matches how much milk you need to handle. Whether you run a small farm or a big dairy plant, you’ll find a model that fits.

Built to Last:

Every tank is built from 316L and 304 stainless steel, giving you heavy-duty, rust-free gear that wipes clean in minutes. Those materials are the gold standard in food and drink, so you meet every hygiene rule and keep the equipment working for years.

Smart Energy Use:

Thanks to that wide power range, the tank uses energy only when it needs to, helping you keep bills in check. Each unit is tuned to deliver peak mixing without eating extra power, so it does the job without costing a fortune.

Applications of the Milk Mixing Tank

1. Dairy Production Facilities

Birthday cake milkshakes, mango lasso powder, or in ice cream, factory-scale mixing tanks fold flavors together, so every sip tastes exactly the same. They swirl sugar, stabilizers, and colors straight into fresh milk, then pump the smooth blend onward.

2. Yogurt and Cheese Production

Even tiny lumps in yogurt or cheese can ruin a line, so gentle mixing keeps cultures, salt, or thickening agents from settling. Tanks watch temperature and speed while ingredients slide in, letting makers hit the perfect acidity and finish every time.

3. Smoothie and Beverage Manufacturing

Smoothie plants hate floaties, so milk mixing tanks smash frozen fruit, protein powder, and milk into a creamy swirl. Vortex-style blades pull everything into the center, snapping bubbles before they grow and keeping the shelf life longer.

4. Pharmaceutical Applications

Labs that mix calcium-rich baby formulas or dairy-based protein gels for hospital diets rely on the same predictable process. Here, weighing and warming happen inside the lid, and every batch leaves the line with the same strength and taste.

Key Specs:

- Voltages: Pick from 110V, 220V, 380V, 440V—or go all the way up to 600V—so it works no matter where you plug in.

- Power Ratings: Choose from 1.5KW up to 55KW, so both tiny farms and big plants stay covered.

- Material: Go with top-level 316L stainless for salty spray or the pocket-friendly 304 grade that still lasts.

- Tank Size: Tell us how much you need, and we’ll build a tank that matches your daily batch run.

- Mixing Speed: Heavy-duty paddles spin smooth for a blend that never leaves lumps.

- Temp Control: Add heaters or chillers to keep milk at the sweet spot all through production.

- Clean-Up: Well-placed drains, rounded corners, and bright steel mean you spend less time scrubbing.

Why Pick Our System?

Our mixing tank works hard to give you steady batches, speed up the line, and keep your crew on the job. With many volt and what choices, it slips easily into old or new setups. Whether you run a local dairy or a nationwide brand, custom options scale up as orders grow.

Call to Action: Order Your Milk Mixing Tank Today-or Let’s Build One Just for You!

Want to run your dairy line a little smoother? Our durable milk mixing tanks help you blend, store, and pour with less hassle, so every batch tastes the same. Reach out now, and we can go over specs, show you options, or design a tank that matches your shop.

Frequently Asked Questions (FAQs)

Q1: What size tank should I get for my dairy plant?

A: It really comes down to how much milk you move in a shift. We stock mini tanks for small farms, all the way up to heavy-duty units for plant lines. Share your daily numbers, and we’ll point you to the model that works.

Q2: Can I choose the voltage and power for my mixing tank?

A: Absolutely! We set machines up with anything from 110V-600V and power ratings between 1.5KW-55KW, so it fits your local supply and load.

Q3: How do I keep the tank clean while using it?

A: Each tank is built from 316L or 304 stainless steel, which wipes down fast and resists rust. Just follow the usual clean-in-place steps, and you’ll stay well within health standards.

Q4: How long can I expect the milk mixing tank to last?

A: If you take care of it, a tank built from 316L and 304 stainless steel will keep working well for many years.

Q5: When I buy the tank, does shipping include putting it in place?

A: We’re happy to set up the tank for you, but availability depends on where you live. We’ll walk you through the steps, and if it’s easier, our team can come out and do the job.