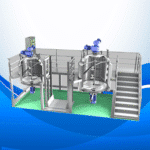

High-Speed Detergent Mixing Tank: Fast, Accurate Blending for Bulk Soap Production

When factories set out to make liquid dish soap, laundry detergent, or heavy-duty industrial cleaner, they don’t want cloudy batches or unplanned downtime. That is why the high-speed detergent mixing tank uses cutting-edge agitator blades, temperature control, and mass flow sensors that work together to trim turnover time and give managers real-time data they can trust.

Key Features and Benefits

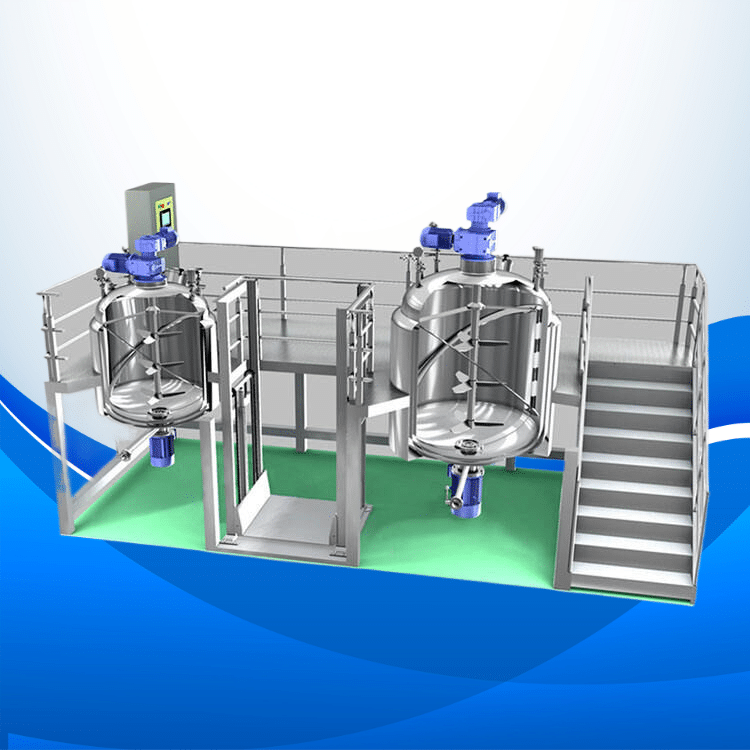

Every detail of the tank-from its bevelled lid to the double-jacketed vessel walls-has been tuned for lean production, yet the footprint stays small enough to slide into an L-shaped line without moving every conveyor. Operators say they appreciate the quick-clean valves and the color-coded hose hookups, which cut changeover delays that otherwise drag on for hours.

Super-Fast Mix Time

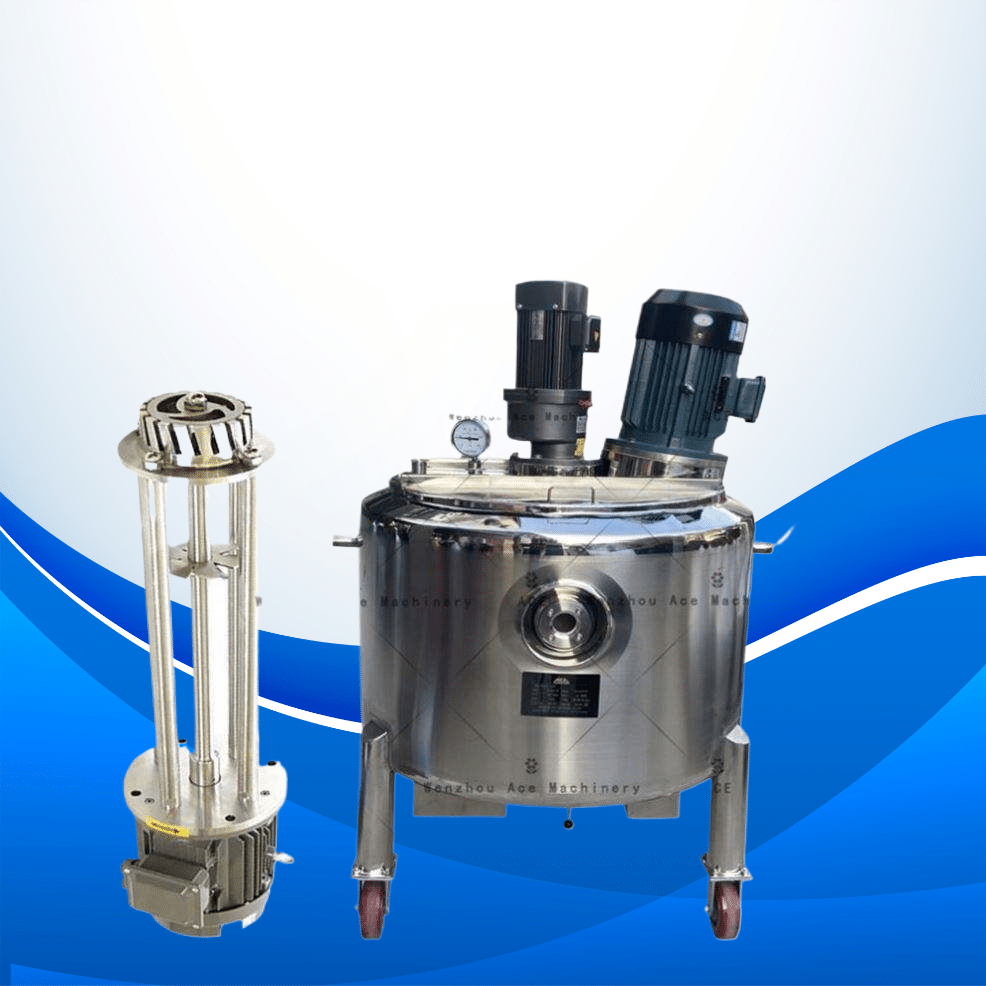

The swirl plate spins at 3,600 rpm so boosters, dyes and enzymes are fully blended in under ten minutes, freeing staff to prep the next batch.

Smart-Control Package

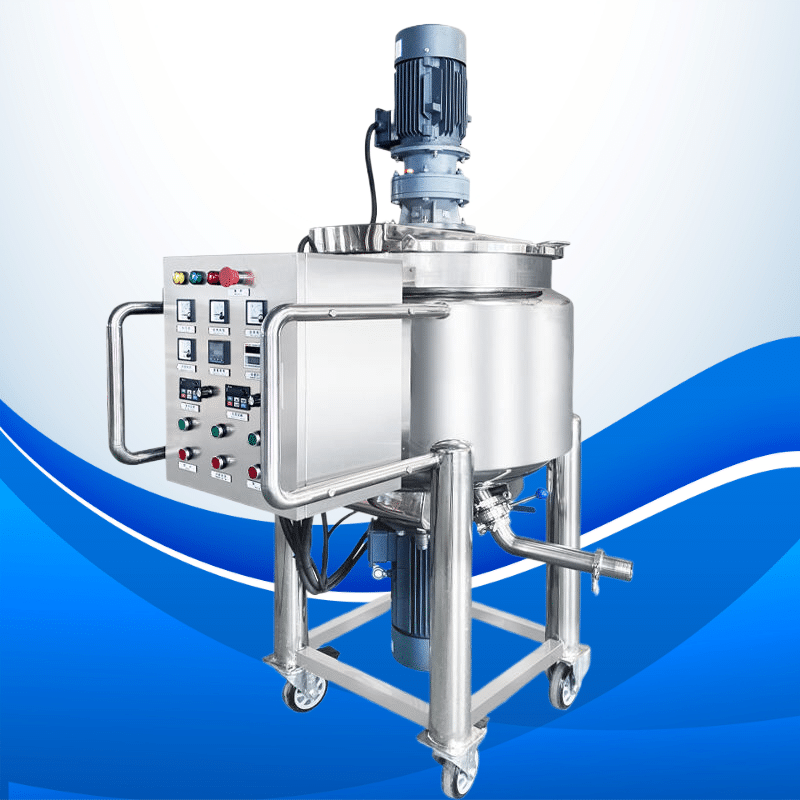

A touch-panel PLC tracks speed, power draw and temperature, and alarms on out-of-range readings, so a fresh operator can run the unit with minimal handover training.

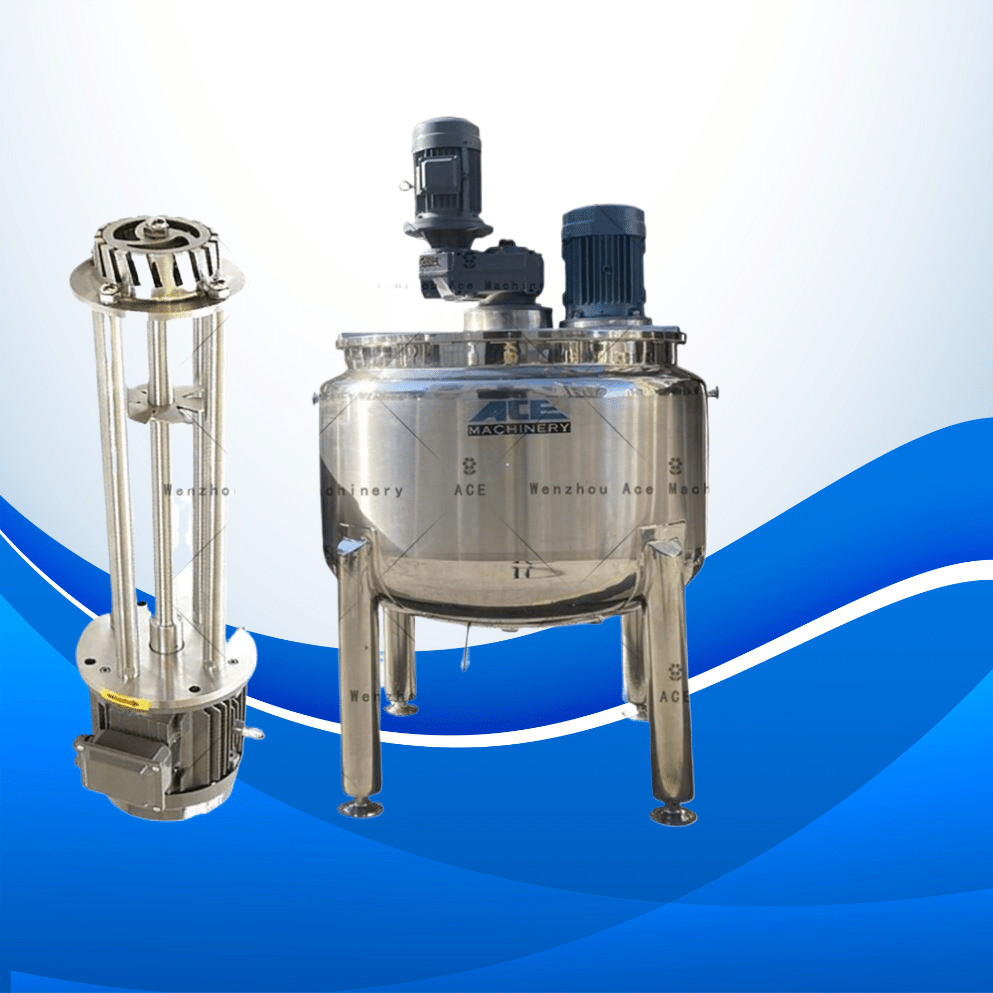

Build-Grade Options

Customers choose 304 for everyday blends or 316 for corrosive acids, plus alloy-welded lids, sanitary sight-glass and easy-lift lids that keep maintenance tools to a minimum.

Real-World Applications

Whether you run a big detergent plant or a smaller chemical-blending shop, high-speed mixing tanks quickly become your best buddy. Youll find them in:

- Household Detergent Production-making liquid laundry soap, dishwashing gels, and all-purpose cleaners.

- Personal Care Manufacturing-blending body wash, shampoo, and everyday hand soaps.

- Industrial Cleaning Solutions-crafting degreases, heavy-duty cleaners, and floor-maintenance liquids.

Picture this: You knock out a 1,000-liter batch of concentrated detergent in minutes-without lumps or bad streaks. The tank is more than just a container; its a production partner that lifts quality, cuts labor bills, and gives you the same great result every time.

Technical Specifications

| Feature | Specification |

|---|---|

| Capacity | Tailored to your project |

| Voltage | 110V-600V |

| Power | 1.5 kw-55 KW |

| Material | SUS304 or SUS316L |

| Mixing | High-speed shear |

| Control | PLC or Digital display |

Each tank is built to last, fitted with top seals, easy-to-clean surfaces, and plug-and-play parts, so service is a breeze.

Why Choose Our Mixing Tank?

- Made for You: Custom-built to fit your formula and output.

- Sips Energy: Uses less power but keeps up the blend speed.

- Tough Build: Shrugs off corrosives and keeps running.

- Globally Approved: Carries CE, ISO, and other first-class badges.

Ready to Boost Your Bottling Line?

Step up to a speedy detergent-mixing tank that puts reliability first. Whether you’re launching a fresh line or improving an old one, our team handles the planning, design, and set-up so everything fits together.

Drop us a line and tell us what you need; well send a quote made just for you. We also do custom-brand tanks, and world-wide shipping comes standard.

FAQ

Q: What’s the real difference between 304 and 316L stainless steel?

A: 316L fights rust better than 304, especially around salty or chlorine-heavy blends, so it works well with stronger detergent mixes.

Q: Can I order a tank in my own size?

A: For sure. We adjust the tank size, stirrer speed, and control panels to match your daily output.

Q: Will you help me set it up?

A: Of course. We offer video support and, if needed, on-site training for customers outside your country.

Q: How long will a custom order take?

A: Most orders ship in 15 to 30 working days, though bigger or more complex builds can add a few days.