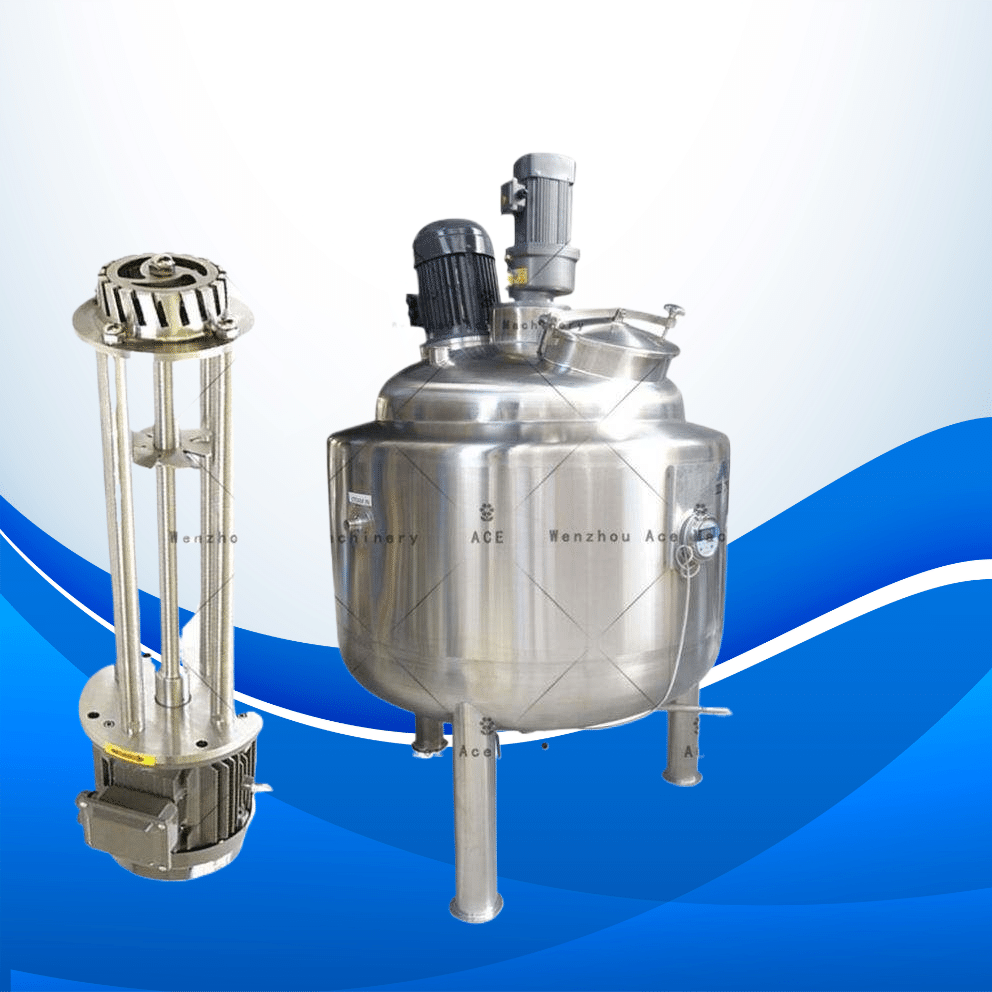

Product Description: Heat Jacketed Mixing Tank, China

The Heat Jacketed Mixing Tank made in China is a heavy-duty blender built to heat and stir liquids smoothly in many factories. Whether you’re working with chemicals, medicines, food, beauty products, or something else, this tank gives you the power to set the right temperature and speed, helping you make a better product, faster.

Key Advantages of Heat Jacketed Mixing Tanks

Better Heating Across the Board:

Thanks to its heat jacket, the tank warms material evenly from the outside, so nothing burns or sits in a cold spot. The jacket wraps all the way around, avoiding hot patches that can ruin sensitive recipes like glues, creams, or thick pastes. When precise heat counts, this design really shines.

Rough-and-Ready 316L/304 Stainless Steel:

Built from 316L or 304 stainless steel, every tank stands up to rust, scratches, and long hours of use with almost no fuss. Pick the grade that matches your fluid, and the vessel keeps working day after day, even in tough factory air.

Wide Voltage Range (110V to 600V):

Our mixing tanks come with a voltage range from 110V to 600V, so they fit almost any outlet around the planet. This wide choice keeps them in sync with your current setup and makes hook-up simple.

Customizable Power Capacity (1.5KW to 55KW):

You can pick a heater that runs from just 1.5KW all the way up to 55KW, letting the same tank work in tiny shops or big factories. Choose the level that matches your output and you will save both power and time.

Precise Mixing Control:

The motor speed is easy to tweak, giving you exact control over how fast things spin. Whether you’re swirling thick pastes, dry powders, or wet slurries, the mixer keeps everything even and cuts down batches that go wrong.

Applications and Real-World Usage Scenarios

For any process that must stay at a steady temperature while mixing, a Heat Jacketed Mixing Tank from China is a secret weapon. Here are some places you will find them busy.

Pharmaceutical Industry:

In drug plants, these tanks make it possible to turn out creams, gels, and liquid meds that are the same from jar to jar. Gentle heat protects fragile ingredients, so every dose is as strong as the last one.

Food Processing

Heat-jacketed mixing tanks are the go-to workhorses in many food plants. They gently cook sauces, jams, pastes, and other delicate products without scorching, spreading the heat evenly so every drop tastes and feels the same. Because the process is so gentle, vitamins and other nutrients stay put, keeping the food both yummy and wholesome.

Cosmetic Production

In the world of skin care and beauty, these same tanks help make creams and lotions that look smooth on the shelf and the skin. By carefully controlling the temperature, manufacturers keep fragile oils, extracts, and thickeners from separating or curdling, meaning customers get a reliable product every time they dip in a jar.

Chemical Manufacturing

Heat-jacketed tanks also serve chemical makers who need steady heat for reactions to succeed. Whether producing adhesives, specialty paints, or niche resins, the precise, even warmth inside the jacket translates into cleaner batches and fewer quality headaches further down the line.

Technical Parameters and Customization Options

Material

For parts that meet food or pharma standards, 316L stainless steel fights rust and corrosion like a champ. 304 stainless is an easier-on-the-budget choice when ingredients are less aggressive but still demands clean, careful handling.

Voltage Options

Bench top labs or small factories can work with the 110-V version. The 220-V model covers almost every midsize plant, while the 380-V to 600-V range suits megafactories that pull serious power.

Power Capacity

A 1.5-kW tank is enough for small runs, letting start-ups test recipes without big bills. Units that push up to 55 kW keep pace with heavy lines, so thousands of liters move in hours, not days.

Why Choose Our Heat-Jacketed Mixing Tank?

When you pick our heat-jacketed mixing tank, you get more than trendy features-you get dependable gear that keeps your line moving smoothly. The tanks are built to save energy, fit neatly into your setup, and can be tweaked in lots of ways.

Heated walls, stronger materials, even special voltages are all easy options so your mixing-and-warming job is done right the first time.

Order Today or Customize Your Heat-Jacketed Mixing Tank

Want to boost your production speed? Give us a shout, and well either ship the thank you see or build one to your exact needs. Our friendly experts walk you through choices, answer questions, and make sure you leave with the right gear.

Frequently Asked Questions (FAQ)

What industries can benefit from using a heat-jacketed mixing tank?

Pharma, food, chemicals, cosmetics-pretty much any line that needs even heat and gentle mixing relies on these tanks.

Can I customize the voltage for my tank?

Absolutely! We offer voltages from 110V all the way to 600V, so the tank plugs right into your plant.

What is the maximum power capacity available for the heat-jacketed mixing tank?

The top end is 55 KW, powerful enough for heavy-duty factory work.

What materials do you use to build the heat-jacketed mixing tanks?

You can pick either 316L or 304 stainless steel, depending on what your job needs.

Can you make a tank that fits my exact needs?

For sure! We customize the power, voltage, material, and size just for you.

If you want top-notch mixing and heating tech, our heat-jacketed tanks from China are the answer, should call us and let’s talk about your custom order today!