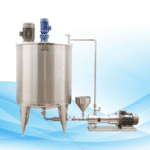

Product Description: Emulsifying Mixing Tank

An emulsifying mixing tank is a must-have tool for any factory that needs to blend ingredients super smoothly. Whether you’re whipping up salad dressing, lotion, medicine, or cleaning chemicals, this tough unit gives you a lump-free mix every time. Built with modern tech, the tank takes on heavy-duty jobs without breaking a sweat, so you’ll see fast, reliable results day after day.

Key Features and Advantages

Superior Emulsification Efficiency

Thanks to high-shear rotor-stator action, the tank pulls stubborn liquids—un-mixable oil and water—together into a stable emulsion. That power is why food plants, cosmetic labs, and drug makers trust it whenever uniform looks and feel matter.

Customizable Power Options 1.5KW to 55KW

Nobody wants motors that are either too weak or oversized, so this mixer comes in 1.5KW trims for small runs all the way up to a giant 55KW model for nonstop factories. Pick the version that suits you now and swap later as volume climbs, keeping performance spot-on without wasting energy.

Voltage Flexibility (110V to 600V)

Plugging in the emulsifying mixing tank is simple, no matter where you are. Its voltage range of 110V to 600V means it can work with just about any power feed you already have. North American and European lines are covered, and Asian grids fit too, so your set-up will run smoothly from day one.

Durable Construction with 316L & 304 Stainless Steel

Engineers built the tank to last, using either 316L or 304 stainless steel. Both grades shrug off rust and chemical damage, so you don’t have to worry about corrosion ruining your investment. Opt for 316L when you’re handling acidic or alkaline batches—it’s the go-to in food and drug plants. Go with 304 when the materials are milder; it saves money yet still does the job.

Versatile Application Across Industries

Because of its design, the emulsifying mixing tank fits a ton of different factories and recipes, including:

- Food: whisking sauces, mayo, dressings, creams, and dairy.

- Cosmetics: blending lotions, shampoos, and creams that need a smooth feel.

- Pharmaceuticals: mixing emulsions for ointments, gels, and bulk creams.

- Chemicals: stirring adhesives, paints, coatings, and lubricants.

With one machine, you can switch from snacks to serums—with a quick clean—and keep the line moving.

Built for Simple Use & Easy Care

The emulsifying mixing tank was designed with straightforward controls and an uncluttered layout so even new team members can jump in quickly. Its quick-disconnect agitator and blade setup lets you pull parts off with a gentle twist, speed-clean the pieces, and put them back in under minutes. That keeps everything fresh and meets the hygiene rules everyone has to follow.

Top-Notch Safety Features

Behind the scenes, the tank watches your process for you. Over-heat sensors, pressure relief valves, and motor overload cut-outs work together to catch problems before they become headaches. Because of that, operators can focus on their task knowing the gear has their back.

How the Tank Boosts Your Line

Picture this: you’re developing a new skin cream and every ingredient has to blend in just the right way. With this tank, oils, water, and actives pull together into a silky mix, ready to fill jars without lumps or separation. Or swap the scene to a food plant making mayonnaise. The same machine keeps every batch at the same velvety thickness, cutting waste and boosting shelf appeal.

No matter what you make, the emulsifying mixing tank gives you steady, high-quality results with far less fuss.

Product Specifications:

- Power Range: 1.5KW to 55KW (we can adjust this to fit your job).

- Voltage Range: 110V to 600V (meets almost any world plug).

- Material Choices:

- 316L Stainless Steel: ideal for harsh, sterile, or pharma uses.

- 304 Stainless Steel: a budget-friendly pick for most general tasks.

- Tank size sets capacity: from benchtop labs to huge plants.

- Max Speed: up to 3000 RPM, depending on motor size.

- Temp Range: -10C to 150C, depending on parts inside.

- Max Pressure: 3 bars, and we can tweak that if you ask.

Why Pick Our Emulsifying Tank?

- Tailor-Made: size, power, and material meet your real needs.

- Superior Blend: our tech gives smooth mixes, great feel, and steady quality.

- World Ready: with 110 to 600 volts, the unit plugs in almost anywhere, so border worries fade.

- Built to Last: tough stainless keeps working long in the roughest shops.

Call to Action:

Want to step up your production line with the most dependable mixing tank around? Our team builds each unit to match your needs, big or small. Get in touch today for a free chat, or order now and enjoy the perfect mix of power, strength, and flexibility.

If you have questions or want a special design, just drop a line to our friendly sales crew. We’ll gladly guide you to the best emulsifying tank for your operation.

Frequently Asked Questions (FAQs):

- 1. Can I customize the size of the mixing tank?

- Absolutely; we offer tanks from lab-bench size all the way up to large industrial units.

- 2. What voltage options are available?

- The tanks can run on anything from 110V home power up to 600V, so they fit almost any plant worldwide.

- 3. Is it suitable for food production?

- Yes, every tank is made of food-grade 316L stainless steel, perfect for sauces, dressings, dairy, and more.

- 4. How easy is the tank to clean?

- Very easy. The agitator and all mixing parts come out quickly, so you spend less time cleaning and more time running.

- 5. Can I use the tank in a pharmacy?

- Absolutely. Its 316L stainless steel and spot-on mixing power make it great for pharmacy-quality creams and ointments.

- 6. How do I ask for a price on a custom tank?

- Just reach out to our sales crew by phone or email, and we’ll size up what you need and send you a quick, custom quote.