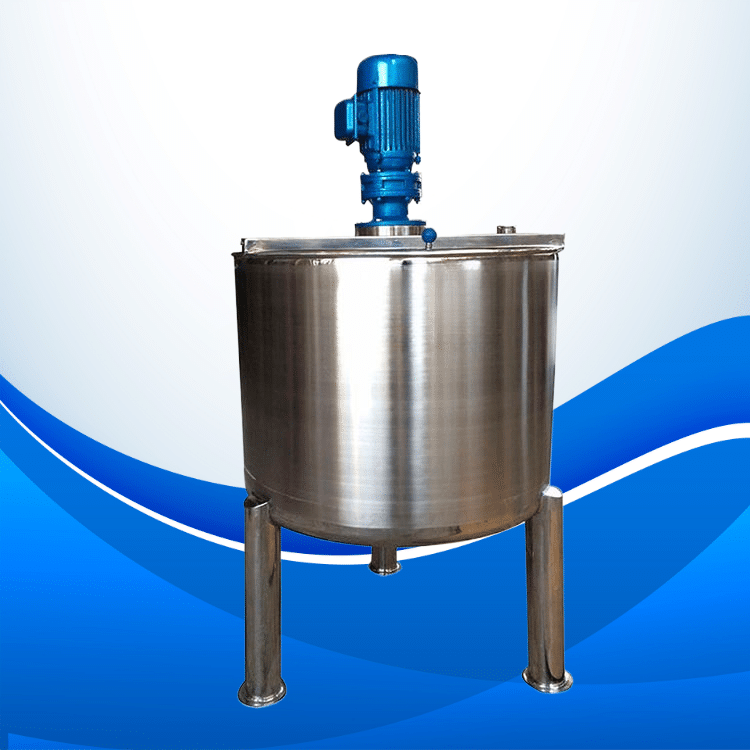

Introduction to Glycol Mixing Tanks

Glycol mixing tanks play a crucial role in a wide range of industrial applications where fluids need to be cooled or heated in a controlled manner. By blending glycol and water to the exact ratio required, the tank guarantees that chillers, heaters, and HVAC units get stable, ready-to-use solutions. Whether you operate a compact production line or a sprawling facility, this rugged, thoughtfully engineered unit keeps your heat-transfer system running smoothly and reliably.

Key Features and Advantages

Customizable Voltage and Power Options

Designed for today’s diverse power environments, the mixing tank accepts voltages from 110V to 600V and can be configured with heaters rated anywhere between 1.5KW and 55KW. This wide range lets you match the unit’s electrical load to your facility’s supply without expensive upgrades, whether on a small bench in a workshop or mounted in a large factory energy plant. Because the system starts ready for your setting, commissioning time is shortened and the risk of costly supply-mismatch problems is nearly eliminated.

Durability and Corrosion Resistance

Built for the long haul, our glycol mixing tanks come in two top-grade stainless steels: 316L and 304. Both grades resist rust and corrosion, a vital trait when you work with glycol that can be chemically tough on surfaces. If your facility sees the harshest chemicals or saltier air, 316L is the safer bet; for everyday industrial use, 304 does the job. Either choice keeps the tank sound even under extreme shifts in pressure or temperature, so you slash the money and time spent on repairs and outages.

Enhanced Efficiency for Heat Transfer

These tanks streamline heat-exchange operations by producing a steady, well-blended glycol solution. When your fluid enters pipes already uniform, pumps and coils work less hard, consuming less energy and delivering faster, steadier results. Customers regularly report lower electric bills and longer equipment life in HVAC, chiller, and thermal-storage setups after upgrading to these blended tanks.

Precision Mixing

Fitted with smart agitators and sensors, each tank delivers constant, on-target mixing of glycol and water. That steady ratio cuts the risk of hotspots or icy spots in the network, keeping every square meter of your system running as it should.

Applications and Use Cases

Glycol-mixing tanks find their place in a wide range of industries and day-to-day tasks. In HVAC systems, they keep air at set temperatures, boosting the cooling or heating power of big commercial setups.

The refrigeration sector, especially in cold-storage warehouses and food plants, relies on a steady, well-balanced glycol blend for quick chilling. Here the tank helps the mix stay exactly as it should so heat moves efficiently and products stay fresh.

In solar thermal installations, the unit blends the fluid that moves collected heat to storage, helping panels work smoothly all day.

Factories that demand tight temperature control—and that includes injection-molding or die-casting lines—also see real gains when a dedicated tank is involved.

Even in chiller plants, common in larger buildings, the stand-by tank guards against freeze-up by making sure the circulating fluid carries the right freeze point and volume.

Specifications and Customization Options

- Voltage Options: range from 110V to 600V in 50-60Hz.

- Power Ratings: span from 1.5kW through 55kW.

- Material Choices: For harsher environments, 316L stainless steel is offered, while 304-grade material suits more standard duties.

- Tank Size: Tailored, whether for small jobs or full production.

- Mixing Speed: Adjustable, letting technicians set the shear rate needed for any glycol blend.

Why Pick Our Glycol Mixing Tank?

- Remarkably Reliable: Built rugged so it keeps running even in non-stop, demanding settings.

- Energy Smart: Engineered to use less power while still giving you a perfectly mixed glycol batch.

- Long Life: High-grade stainless steel resists rust and wear, giving the tank years of dependable service.

- Custom Fit: Voltage, finish, and even tank size options let you match the system exactly.

Call to Action: Order Today or Request Customization

Put the tank into operation and enjoy better performance plus lower energy bills almost at once. Our experts can also build a version tailored just for you, so you never settle for half measures. Reach out today, and we’ll give you fast, friendly answers and a detailed quote.

Frequently Asked Questions (FAQs)

1. What is a glycol mixing tank used for?

A glycol mixing tank blends glycol with water or other fluids to create the right formula for heating and cooling setups. Industries count on it whenever a glycol loop, in chillers, heat pumps, or refrigerants, must work efficiently and reliably.

2. Can I customize the size of the glycol mixing tank?

Absolutely! We offer several tank capacities, so you can choose a small portable unit or a massive industrial model that matches your setup.

3. What is the best material for a glycol mixing tank?

Most customers go with 304 stainless steel because it handles mild conditions well, but 316L grade is available if your system faces heavy salts or acids.

4. What voltage and power options are available?

Voltages range from 110V single phase to 600V three-phase, and power ratings vary from 1.5kW small system heaters up to 55kW for large installations.

5. How do I maintain the glycol mixing tank?

Regular visual checks and periodic cleaning of the inside and joints keep the tank running smoothly, and we can schedule full-service tune-ups whenever you like.

6. Can I order a customized glycol mixing tank?

Yes, every tank order begins with a design conversation so you get the features, fittings, and controls that fit your facility exactly.