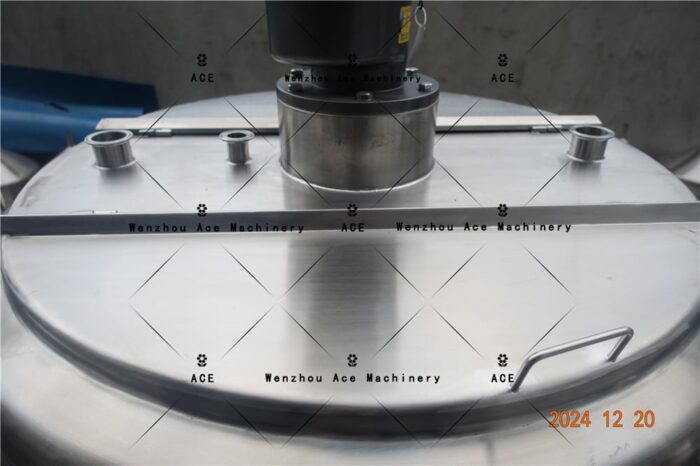

Food Mixing Tank

- Capacity: 50 liters to 30,000 liters

- Mixer power: 1.5 kW to 55 kW

- Material: 304 or 316L

- Voltage: 110V to 600V

- Heating method: Electric or steam heating

- Layer:single/double jacket/three jacket

- Mixer types: Impeller-type, Anchor-type, Turbine-type, High-shear-type, Magnetic mixer, Anchor-type mixer with scrapers,dispersing

- Optional: platform, wheels, ladder,variable frequency drive,explosion-proof device

- Certificates: ASME, CE, GMP, UL, ATEX, ISO 9001

- Our equipment supports customisation, global delivery, and a 1-year warranty.

- If you have drawings, we can process them for you.

Note: Please contact our sales team before placing an order. Website prices are for reference only; specific pricing requires understanding your requirements to provide a quote.

Email:info@ace-chn.com

Tel: +86 186 2683 5909

WeChat: ace-chn

WhatsApp: +86 186 2683 5909

$3,580.00

Guaranteed Safe Checkout

Recommend RPM: 0-960RPM

Viscosity: Low/medium viscosity

Application: Mainly Liquid mixing

Recommend RPM: 0-200RPM

Viscosity: Low/medium viscosity

Application: Mainly Liquid mixing

Recommend RPM: 30RPM

Viscosity: Medium/High viscosity

Application: Melting, High viscosity product mixing, For single wall tank

Recommend RPM: 30RPM

Viscosity: Medium/High viscosity

Application: Melting, High viscosity product mixing, For jacket tank

Recommend RPM: 1480/2850 RPM

Viscosity: Low/medium viscosity

Application: Liquid powder mixing and dispersion

Recommend RPM: 1480/2850 RPM

Viscosity: Low/medium/High viscosity

Application: Liquid powder mixing and homogenizing

Recommend RPM: 0-355RPM

Viscosity: Low/medium viscosity

Application: Install at bottom, No mechanical seal working condition

Recommend RPM: As above

Viscosity: Low/medium viscosity

Application: Liquid powder mixing and dispersion For tank volume >300L

Food Mixing Tank: Revolutionizing the Food Production Process

Inside any busy food plant, the job of blending raw materials into a consistent mix often falls to the humble mixing tank. From sauces and soups to dairy drinks and cake batters, the right tank keeps every batch smooth and evenly integrated. By replacing manual stirring or outdated equipment, a modern mixing vessel cuts production time, reduces waste, and delivers the same quality night after night.

Built specifically for the demands of high-volume food production, today’s mixing tanks combine ruggedness, flexibility, and operator-friendly controls. They handle delicate shear-sensitive ingredients, resist extreme temperatures, and fit into cramped factory layouts, helping producers streamline every step of the line.

Key Features and Benefits

Advanced Mixing Technology

With smart impeller designs and adjustable turbulence profiles, each tank eliminates pockets of unblended material, guarding against color streaks or flavor drift.

Customizable Voltage and Power Options

Available voltages from 110 to 600 and motors ranging from 1.5 to 55 kW let engineers match power levels to facility capabilities and batch size exactly.

Durable Construction

Carefully welded 316L or 304 stainless shells stand up to acid cleaners and heavy use, cutting downtime and repairs. Every seam, finish, and input conforms to industry hygiene rules, keeping contamination risks at bay while extending the tank’s working life.

Energy Smart

The adjustable power settings on our mixing tanks let you dial in just the energy you need for each batch, helping your team cut bills without sacrificing throughput.

Quick Clean Design

Every corner and controller is shaped for fast, thorough cleaning, so you spend less time on maintenance and more time on production—an absolute must in any food plant.

Widely Useful

From beverage lines to baked goods, these tanks fit every recipe you throw at them, making them an everyday workhorse on the factory floor.

Common Uses for Food Mixing Tanks

Sauce and Condiment Mixing

Add oils, vinegars, spices, and sweeteners in any order, and the tank will produce a smooth batch—no lumps or color streaks—guaranteeing the same taste every time on store shelves.

Dairy Production

In yogurt, ice cream, and milkshake lines, the tank gently blends milk, cream, and stabilizers for a stable emulsion that stays fresh longer in the freezer and at the cooler door.

Beverage Lines

Juices, smoothies, and flavored waters move quietly through the tank, where a high-efficiency mixer kills air bubbles and settles warnings to serve product free of sediment.

Soup and Broth Production

Food mixing tanks are a must-have when you want to turn fresh ingredients into consistent, high-quality soups, broths, or stews. With gentle, even blending, these tanks give every batch the smooth texture and rich flavor your customers expect.

Confectionery and Bakery Products

The same tank becomes a crucial partner in the pastry kitchen, whipping up batters, frostings, fillings, and glazes. Controlled mixing speed keeps air bubbles in the right place, so cakes rise perfectly and every sweet treat looks as good as it tastes.

Product Specifications

Voltage Options

110V, 220V, 380V, 440V, 600V—customizable to match local power supply and electrical code.

Power Options

From 1.5 kW small lab units to 55 kW lines built for heavy use, each motor gives the torque needed for demanding recipes.

Materials

- 316L stainless steel—finely polished, nearly impervious to salt or acid;

- 304 stainless steel—durable yet budget-conscious for most everyday foods.

Capacity

Compact tabletop models for pilot runs, step-up mid-size tanks for growing bakeries, and wide-opening industrial vessels for major producers—choose exactly what your volume dictates.

Why Choose Our Food Mixing Tanks?

Reliability

Our food mixing tanks are built tough to handle the heavy use found in busy kitchens or factories, giving you a dependable partner that keeps production running day after day.

Cost-Effective

Even with smart features and plenty of upgrade options, these tanks come at a competitive price, so you know you’re getting solid performance without blowing the budget.

Hygienic Design

Crafted to meet the strictest food-safety rules, every tank has smooth surfaces and sealed joints that stop dirt or bacteria from settling in, making them ideal for any food-processing line.

How to Order & Customize Your Food Mixing Tank

Ordering is fast and straightforward. Log onto our website, pick the options that suit your setup, and send the order. If the right voltage, power level, or finish is unclear, one of our tech specialists is just a call away to offer friendly, no-pressure advice.

For larger buys or special designs, contact the sales team directly. We’ll listen to your needs and put together a solution that fits your exact capacity and workflow targets.

Common Questions About Food Mixing Tanks

1. What is the ideal material for my food mixing tank?

316L stainless steel resists corrosion from acidic recipes, while 304 stainless steel works well for less-aggressive ingredients.

2. How do I pick the right voltage and power?

The voltage and power you need really depend on how big your operation is. For the best advice, touch base with our team and let them guide you to the most efficient setup for your line.

3. Are your mixing tanks easy to keep clean?

Absolutely! Each tank is built for easy access, so you can wipe them down, swap out parts, and keep the line moving with very little downtime.

4. Can I order a tank built just for me?

Yes, you can. We design tanks to your exact capacity, power level, and material spec, making sure they fit perfectly into your layout.

5. What about warranty and after-sale support?

All our products come with a full warranty, and our friendly support crew stands ready to help with any question or issue you may run into.

Call to Action

Ready to boost your operation with a mixing tank? Take the next step—tighter mixing, better consistency, and higher-quality batches are just an order away. Contact us today, or place your custom order, and let us help you scale with confidence.