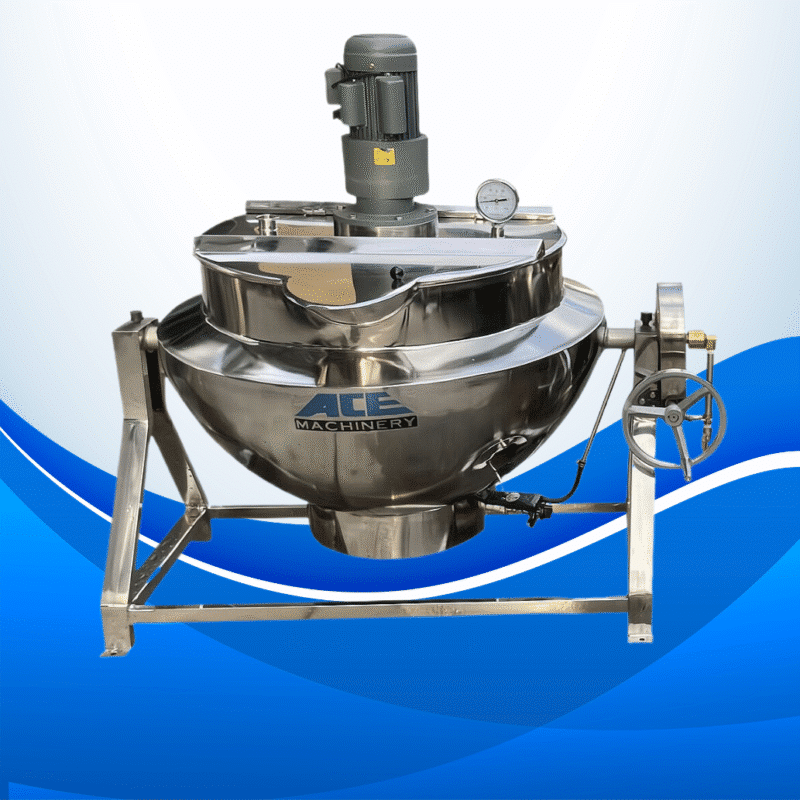

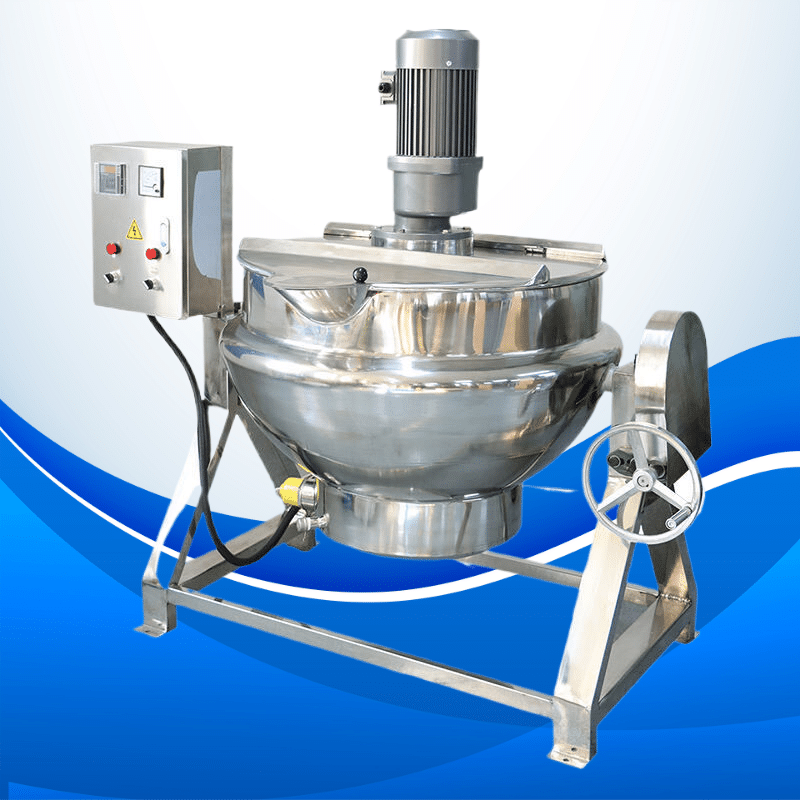

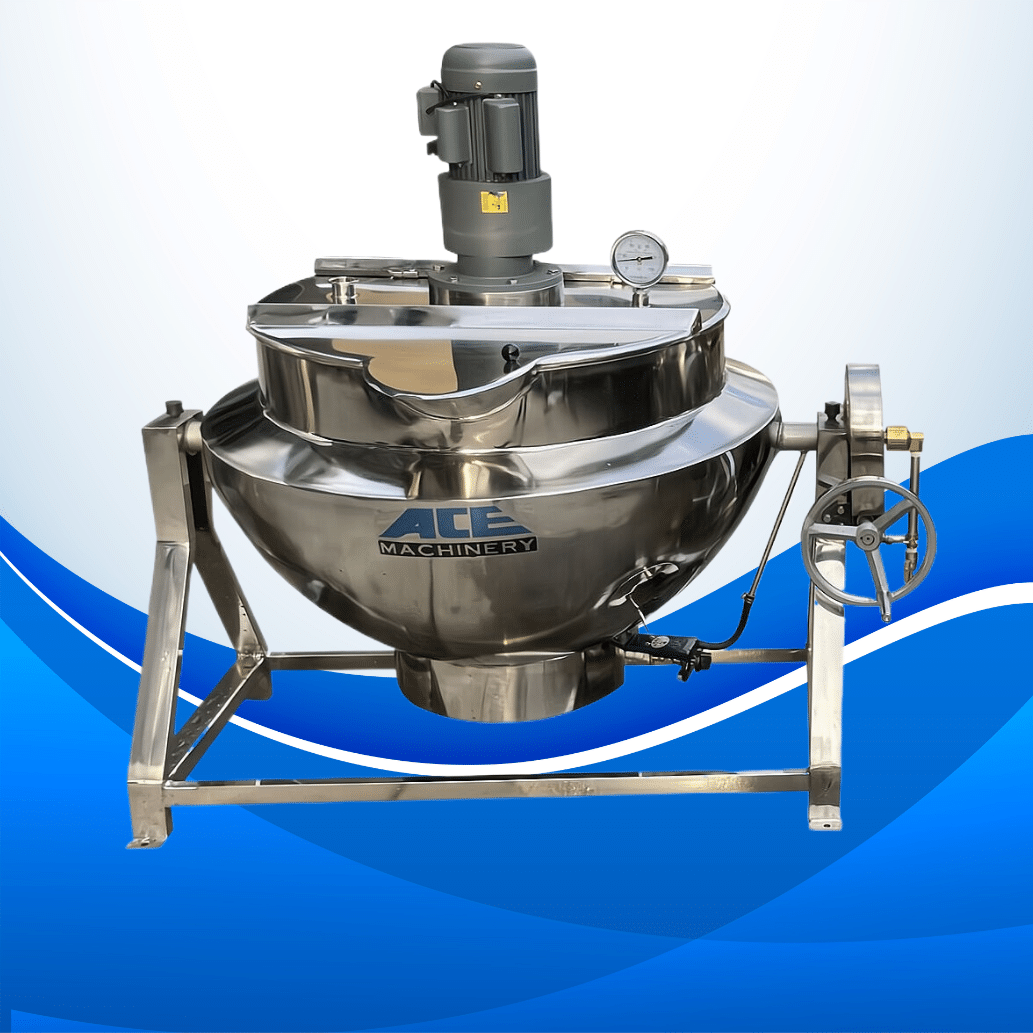

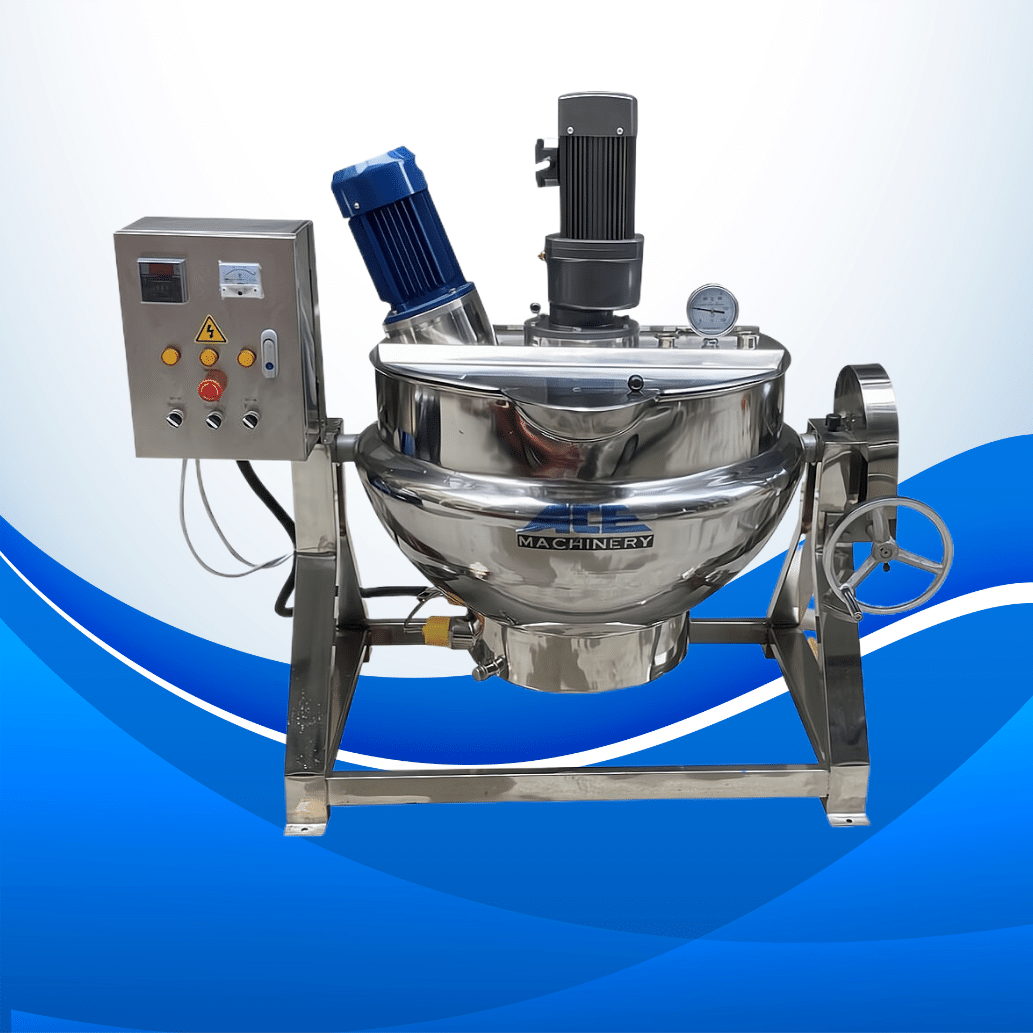

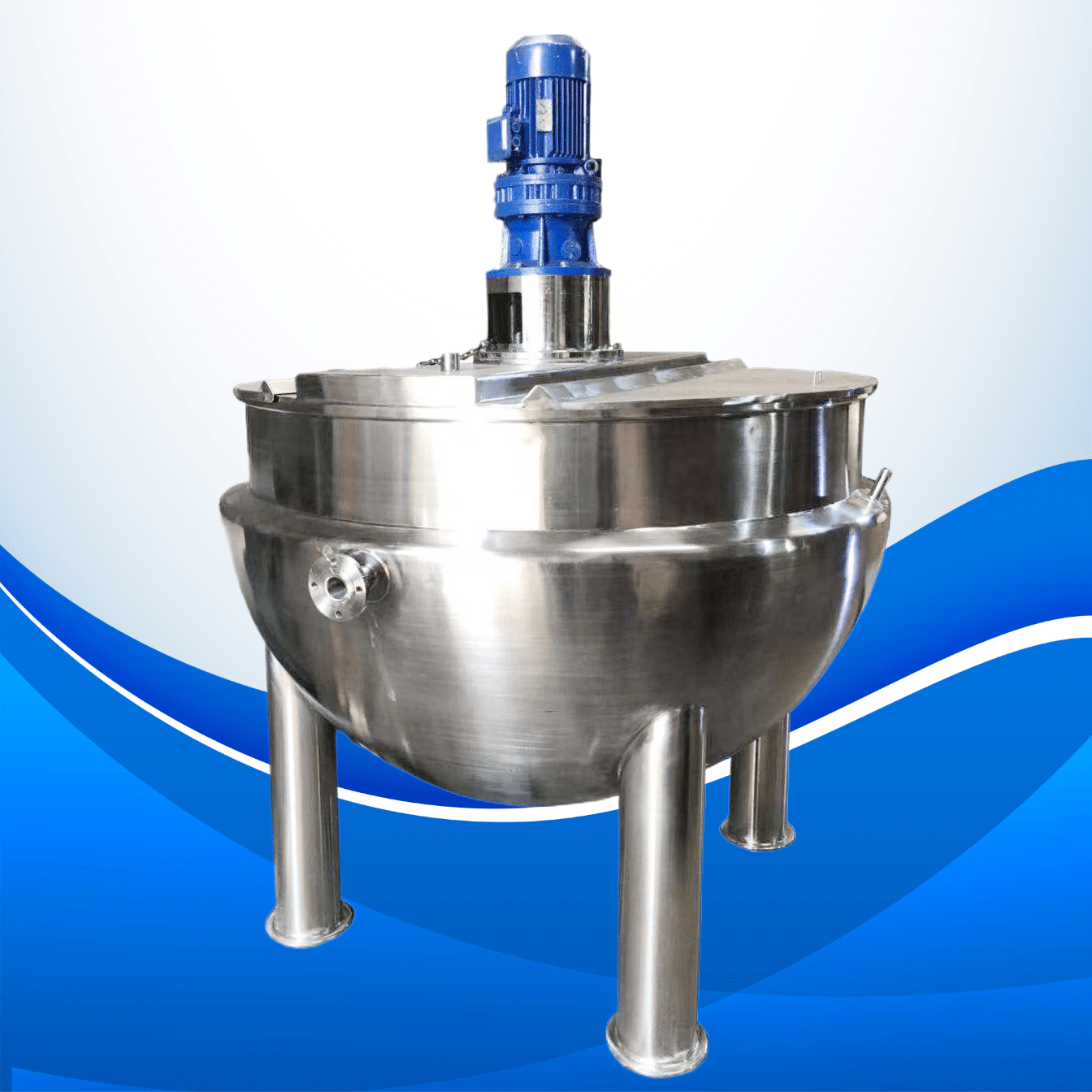

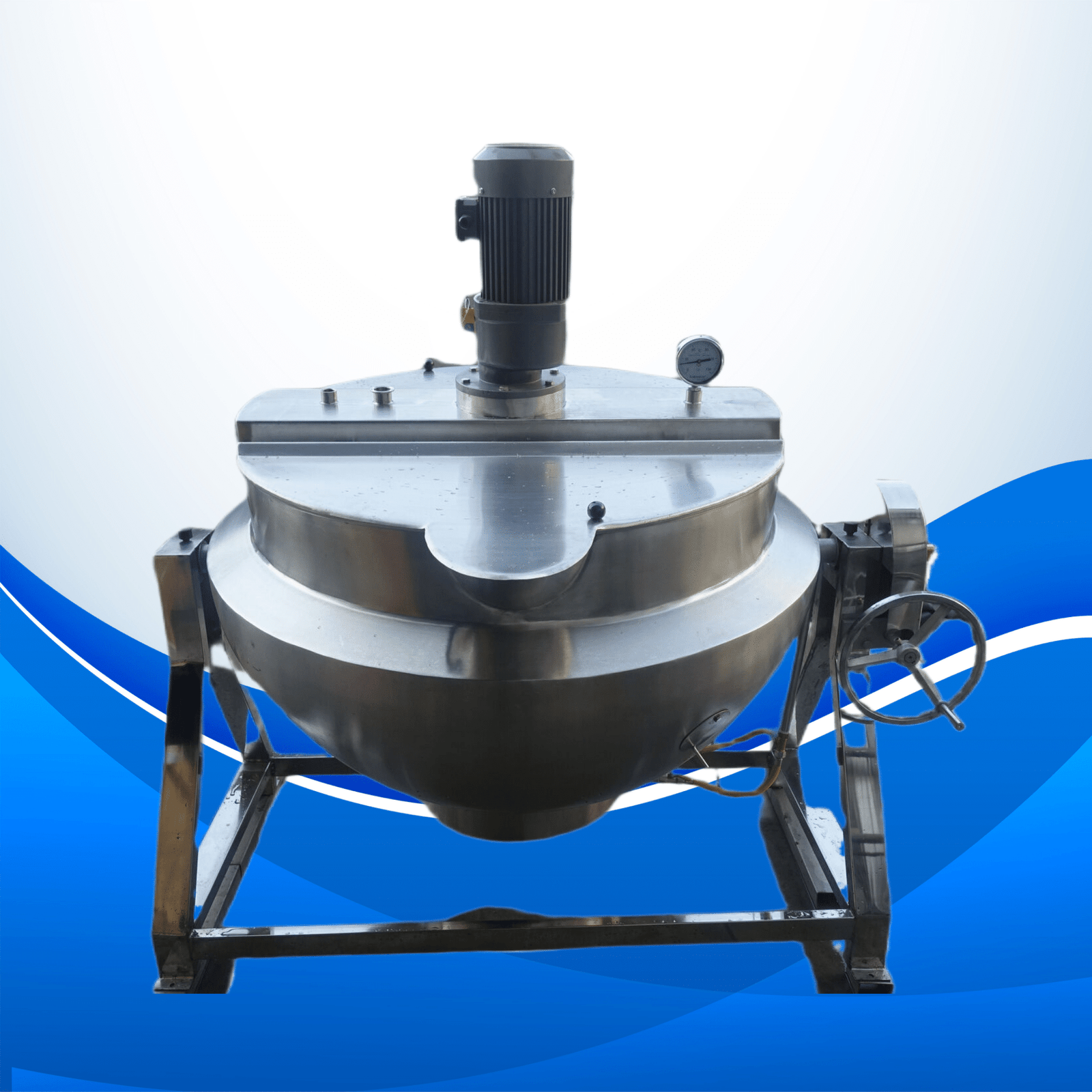

Steam Jacketed Mixing Kettle

- Capacity: 50 liters to 1,000 liters

- Mixer power: 1.5 kW to 11 kW

- Material: 304 or 316L

- Voltage: 110V to 600V

- Heating method: Electric heating, gas heating, natural gas heating, steam heating

- Mixer types: Scraper Mixer, High-Shear Mixer

- Certificates: ASME, CE, GMP, UL, ATEX, ISO 9001

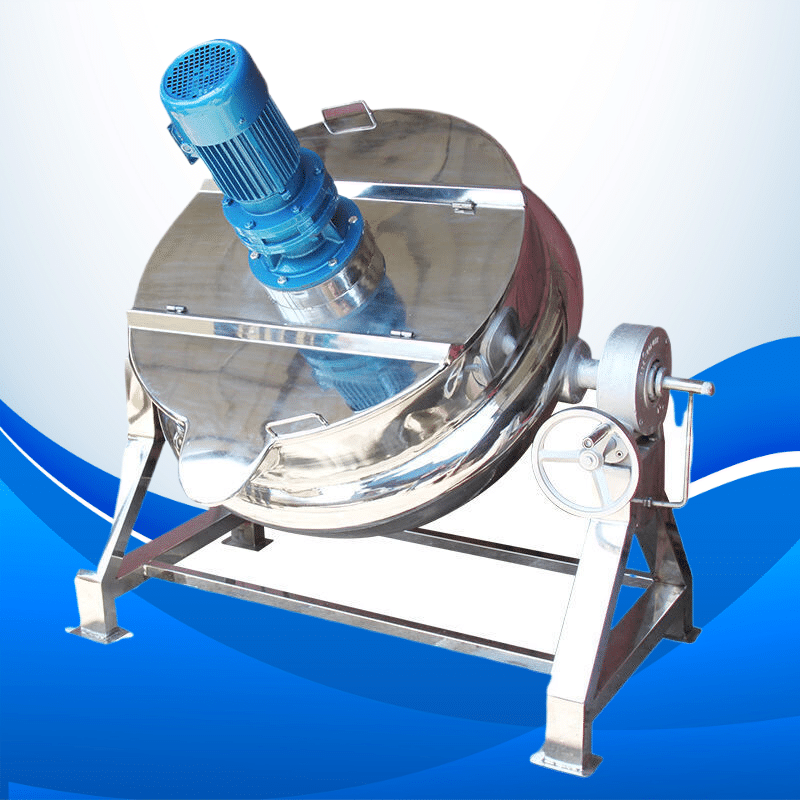

- Optional:Vertical, Tiltable

- MADE IN CHINA

Note: Please contact our sales team before placing an order. Website prices are for reference only; specific pricing requires understanding your requirements to provide a quote.

Email:info@ace-chn.com

Tel: +86 186 2683 5909

WeChat: ace-chn

WhatsApp: +86 186 2683 5909

$2,850.00

Guaranteed Safe Checkout

We manufacture and sell jacketed kettles for electric heating, steam heating, gas heating, and fuel heating applications. Capacities range from 50 liters to 1000 liters.

In busy kitchens and factories making food, beauty products, medicines, or chemicals, a steam-jacketed mixing kettle is nearly indispensable. Built to heat and mix at the same time, it helps every batch come out the way you want, leading to better quality and quicker turnarounds.

Key Features and Benefits

Flexible Heating

Pick steam, natural gas, LPG, or electric heat to match your shop layout and save energy.

Tough Materials

It comes standard in 304 stainless steel for most food jobs or steps up to 316L for salty, acidic, or ultra-clean work, so it lasts and stays sanitary.

Capacity Choices

Ranges from 50 liters for craft runs to 1000 liters for big plants, fitting small or large production curves.

Easy Voltage Match

Available in 110V, 220V, 380V, 400V, and 480V, letting you plug into the shop power already in place.

Powerful Agitation

Motor ratings from 1.5 kW to 11 kW deliver steady stirring, even through thick or heavy mixes.

Safe, Precise Use

The steam jacket spreads heat evenly, cuts burn-on, and keeps every batch consistent from start to finish.

Real-World Application Scenarios

Food Factories

These kettles cook sauces, soups, candy syrup, jams, and delicate dairy dishes while stirring gently so nothing burns or sticks together.

Cosmetic Shops

They emulsify creams, lotions, and gels, keeping heat steady and every drop mixed the same.

Chemical Plants

They handle thick, heat-sensitive batches that can’t tolerate hot spots during blending.

Say you are cooking fruit jam; the kettle heats and stirs at just the right temperature for pectin to set, so you spend less time watching the pot and every batch comes out the same. When you make sauces, it locks in color and flavor without burning, even in very thick recipes.

Durability & Compliance

Built with food-grade parts and tested engineering, the kettle stays safe and lasts longer.

Frequently Asked Questions

Q1: What heating method should I choose for my steam-jacketed mixing kettle?

If you already make steam in your plant, use steam heating-you get the fastest, tightest control. For small lines, natural gas, LPG, or electric save cash upfront.

Q2: Can I process viscous products like caramel or thick sauces?

Absolutely. With agitator options up to 11-kilowatt, the kettle keeps thick batches moving and heats them evenly.

Q3: How do I clean the kettle?

The smooth interior wipes down quick, and you can add a CIP system later so it cleans itself on a schedule.

Q4: Can the kettle be customized?

It sure can. Capacity, voltage, heating method, even shell color-we tailor every detail to your line.