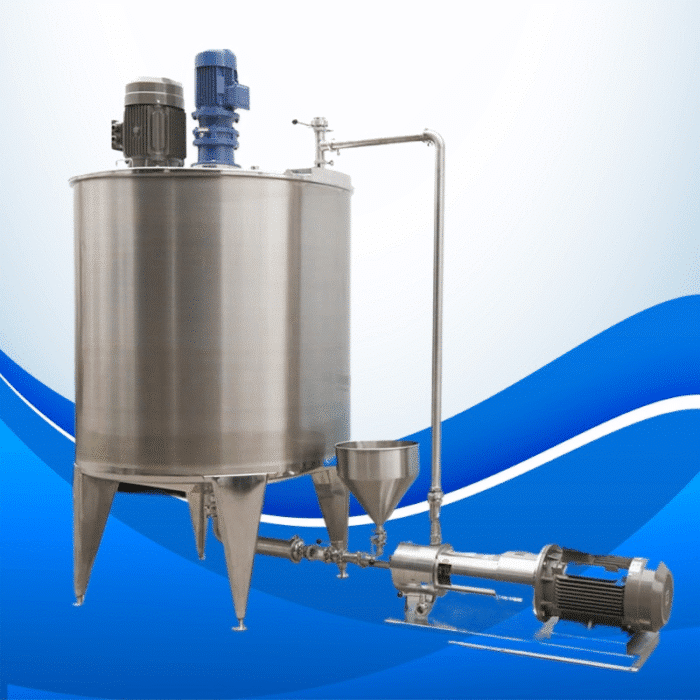

Stainless Steel Mixing Tank Manufacturers

- Capacity: 50 liters to 30,000 liters

- Mixer power: 1.5 kW to 55 kW

- Material: 304 or 316L

- Voltage: 110V to 600V

- Heating method: Electric or steam heating

- Layer:single/double jacket/three jacket

- Mixer types: Impeller-type, Anchor-type, Turbine-type, High-shear-type, Magnetic mixer, Anchor-type mixer with scrapers,dispersing

- Optional: platform, wheels, ladder,variable frequency drive,explosion-proof device

- Certificates: ASME, CE, GMP, UL, ATEX, ISO 9001

- Our equipment supports customisation, global delivery, and a 1-year warranty.

- If you have drawings, we can process them for you.

Note: Please contact our sales team before placing an order. Website prices are for reference only; specific pricing requires understanding your requirements to provide a quote.

Email:info@ace-chn.com

Tel: +86 186 2683 5909

WeChat: ace-chn

WhatsApp: +86 186 2683 5909

$4,100.00

Guaranteed Safe Checkout

Recommend RPM: 0-960RPM

Viscosity: Low/medium viscosity

Application: Mainly Liquid mixing

Recommend RPM: 0-200RPM

Viscosity: Low/medium viscosity

Application: Mainly Liquid mixing

Recommend RPM: 30RPM

Viscosity: Medium/High viscosity

Application: Melting, High viscosity product mixing, For single wall tank

Recommend RPM: 30RPM

Viscosity: Medium/High viscosity

Application: Melting, High viscosity product mixing, For jacket tank

Recommend RPM: 1480/2850 RPM

Viscosity: Low/medium viscosity

Application: Liquid powder mixing and dispersion

Recommend RPM: 1480/2850 RPM

Viscosity: Low/medium/High viscosity

Application: Liquid powder mixing and homogenizing

Recommend RPM: 0-355RPM

Viscosity: Low/medium viscosity

Application: Install at bottom, No mechanical seal working condition

Recommend RPM: As above

Viscosity: Low/medium viscosity

Application: Liquid powder mixing and dispersion For tank volume >300L

Product Description: Stainless Steel Mixing Tanks

When factories need to mix liquids, they want tools that last, work hard, and don’t waste time. That is where we come in. As a go-to maker of stainless steel mixing tanks, we build tough tanks ready to handle the busy pace of food, chemical, and pharmaceutical plants. Our tanks give companies dependable, long-running gear that adapts to nearly any mixing job.

Main Advantages of Our Stainless Steel Mixing Tanks:

Durability and Corrosion Resistance:

Crafted from 316L and 304 stainless steel, each tank resists rust, chemical splash, and high heat far better than regular steel. This heavy-duty build means the tank stays strong for years and cuts how often repair crews are called.

Customization Options:

Every production line has its quirky needs, so we let customers pick the tank height, lid style, or mixer speed they want. Our engineers work with the team to create a one-of-a-kind solution that drops straight into the existing setup.

Energy Efficiency:

Motors from 1.5KW for small batches up to 55KW for big-volume jobs sit under the hood, feeding just the power the job needs. This smart motor choice helps factories stay green while still meeting heavy mixing demands.

Voltage Flexibility:

You can hook our tanks up to just about any standard supply between 110V and 600V, so they fit right into the wiring you already have.

Easy Maintenance and Cleaning:

Thanks to a mirror-like finish on the stainless steel, spills wipe away in seconds and mess can’t cling, making the tanks a true time saver in food, pharma, and chemical workplaces.

Versatility in Applications:

With their sturdy build, the tanks work in any setting—food plants, drug factories, beauty labs, and beyond—so you get steady mixing whether the load is liquid, powder, or something in between.

Common Applications of Stainless Steel Mixing Tanks:

Food and Beverage Industry:

Bakers, brewers, and beverage makers count on them to fold in solids, whip air, or emulsify oils; the rust-proof walls keep flavor pure and spoilage at bay.

Pharmaceutical Manufacturing:

Drug firms need every batch to be clean and accurate; our tanks deliver that by giving creams, gels, and syrups the dust-free, easy-to-sanitize zone they demand.

Chemical Processing:

Plant operators trust the tanks when blending strong acids, dyes, or plastics; the heavy-duty stainless steel shrugs off heat and caustics, keeping people safe while production stays on schedule.

When we make lotions, shampoos, and other beauty items, our clean mixing tanks keep everything super sanitary and mix the ingredients together really well.

Specifications and Features:

- Material Options: pick either 316L or 304 stainless steel

- Tank Capacity: we build to whatever size you need

- Voltage: works with 110V all the way up to 600V

- Motor Power: ranges from 1.5KW to 55KW

- Mixing Type: choose from several blade styles and layouts

- Customization: we adjust tank shape, material, motor, and volts to match your operation

Why Choose Us?

As a top maker of stainless-steel mixing tanks, we go the extra mile to meet tough industry rules. Our tanks are built for solid performance and the long haul, so you can boost productivity without worries. When you partner with us, you get:

- Designs built just for your needs

- Grade 316L or 304 steel that lasts

- Energy-smart motors that save on bills

- Worldwide know-how across many fields

Call to Action:

Want to upgrade your mixing line with a tougher tank? Whether you need a one-off unit or a ready-to-run model, we’ve got your back. Reach out today for a quick chat and see the strength, speed, and flexibility our tanks bring to the table.

Custom Orders and Frequently Asked Questions:

Can I change the size or extras on the stainless steel mixing tank I want?

Sure thing! You can pick the size, capacity, material, voltage, and even how the mixer blades sit.

How long does it take to build a one-of-a-kind mixing tank?

It usually takes 4 to 8 weeks, but the exact time depends on the changes you ask for.

Are these tanks safe to use in food-and-drink settings?

Yes, they are. We use FDA-approved parts and keep everything super clean, so they meet food-industry rules.

What upkeep do I have to do after I buy a mixing tank?

Because they get built for easy access, just checking for wear and giving it a good wash now and then will keep it happy.

Do you help set up the tank once it arrives?

Absolutely. We send clear guides, and if you want, we can even send a pro to do the whole setup for you.

Upgrade your line with a custom stainless-steel mixing tank and watch your operation run smoother and quicker.