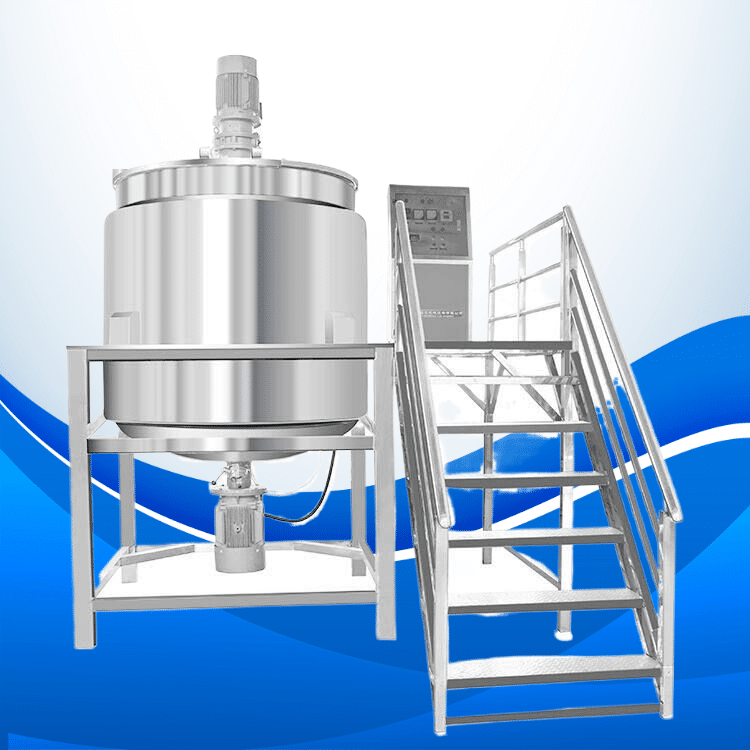

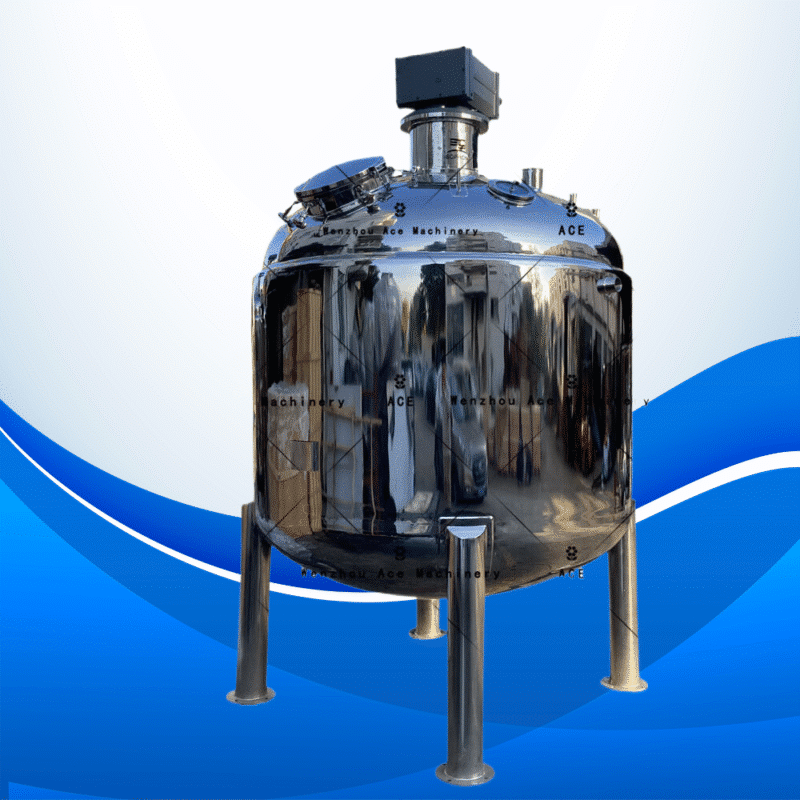

Premium Steel Mixing Tanks for Industrial & Commercial Applications

- Capacity: 50 liters to 30,000 liters

- Mixer power: 1.5 kW to 55 kW

- Material: 304 or 316L

- Voltage: 110V to 600V

- Heating method: Electric or steam heating

- Layer:single/double jacket/three jacket

- Mixer types: Impeller-type, Anchor-type, Turbine-type, High-shear-type, Magnetic mixer, Anchor-type mixer with scrapers,dispersing

- Optional: platform, wheels, ladder,variable frequency drive,explosion-proof device

- Certificates: ASME, CE, GMP, UL, ATEX, ISO 9001

- Our equipment supports customisation, global delivery, and a 1-year warranty.

- If you have drawings, we can process them for you.

Note: Please contact our sales team before placing an order. Website prices are for reference only; specific pricing requires understanding your requirements to provide a quote.

Email:info@ace-chn.com

Tel: +86 186 2683 5909

WeChat: ace-chn

WhatsApp: +86 186 2683 5909

$3,999.00

Guaranteed Safe Checkout

Recommend RPM: 0-960RPM

Viscosity: Low/medium viscosity

Application: Mainly Liquid mixing

Recommend RPM: 0-200RPM

Viscosity: Low/medium viscosity

Application: Mainly Liquid mixing

Recommend RPM: 30RPM

Viscosity: Medium/High viscosity

Application: Melting, High viscosity product mixing, For single wall tank

Recommend RPM: 30RPM

Viscosity: Medium/High viscosity

Application: Melting, High viscosity product mixing, For jacket tank

Recommend RPM: 1480/2850 RPM

Viscosity: Low/medium viscosity

Application: Liquid powder mixing and dispersion

Recommend RPM: 1480/2850 RPM

Viscosity: Low/medium/High viscosity

Application: Liquid powder mixing and homogenizing

Recommend RPM: 0-355RPM

Viscosity: Low/medium viscosity

Application: Install at bottom, No mechanical seal working condition

Recommend RPM: As above

Viscosity: Low/medium viscosity

Application: Liquid powder mixing and dispersion For tank volume >300L

Product Description: Pro-Grade Stainless Steel Mixing Tanks for Everyday Blending

When you need gear that blends well, lasts long, and stays clean, a stainless-steel mixing tank is hard to beat. Built for everything from food plants and drug-makers to cosmetic makers, chemical dealers, and craft brewers, our tanks mix. . . And they mix safely.

Tough Build for Serious Use

Each tank starts life as 304 or 316L stainless steel, giving it solid defense against rust, pressure bumps, and heat spikes. The 304 grade is strong enough and pretty resistant, but the 316L shines in places where extra corrosion or strict hygiene rules matter, like hospitals, labs, and big food lines.

Every tank is tuned for quick mixing and years of uptime. So whether you pour in a few gallons or fill a trailer, you get steady blends, less spilled product, and a cleaner, faster shop floor.

Plug-and-Play Power Options

To fit factories all over the world, we let you pick voltage from 110V to 600V and power from 1.5kW to 55kW. That way, everything from a little mixer to a heavy-duty beast slides right into your panel with no price rewiring.

Versatile Applications Across Industries

Small bakeries or giant factories, everyone seems to need a steel mixing tank these days. Here are some of the most common spots you’ll find them:

Food & Beverage

Tanks blend sauces, syrups, dairy, and drinks while keeping germs away.

Pharmaceuticals

Crews use them to carefully mix creams, gels, and liquid meds under super-clean rules.

Cosmetics

Factories homogenize lotions, serums, and oils so every bottle feels the same.

Chemical Processing

High-grade stainless steel lets people safely stir up even tricky or toxic ingredients.

Brewing & Distilling

Brewers control fermentation and ingredient blending to hit the same taste batch after batch.

Agitators, temperature sensors, vented lids, and drain valves turn a standard tank into your perfect tool.

Key Product Specifications

- Material Options: 304 or 316L stainless steel

- Volume Capacities: Customizable from 50L to 10,000L+

- Voltage Options: 110V / 220V / 380V / 480V / 600V

- Power Range: 1.5kW to 55kW

- Surface Finish: Mirror-polished or brushed

- Optional Features: Heating jacket, cooling coils, CIP cleaning systems, motorized agitators

Why Choose Our Steel Mixing Tanks?

Hygienic & Durable

Stainless steel keeps things clean and lasts through years of heavy use.

Custom Built for Your Needs

Pick the tank size, motor power, voltage, and extras that match your process perfectly.

Reliable Global Shipping

Our logistics pros make sure your order arrives safely, no matter where you are.

Competitive Pricing

You get top-quality equipment without the markup.

Start Customizing Your Mixing Solution

Scaling up or fine-tuning batch quality? A durable stainless-steel mixing tank makes the job easier. Our engineers will craft a design that fits your layout and workflow.

Reach out for a free chat, a custom quote, or details about our ready-to-go models. Once you decide, you’ll have a unit that combines precision and heavy-duty performance.

Frequently Asked Questions (FAQ)

Q: What is the difference between 304 and 316L stainless steel?

A: 316L has molybdenum, so it resists rust better in salty or acidic settings. That’s why food and pharma factories choose it. 304 works well in most other industrial situations.

Q: How do I choose the right power and voltage for my application?

A: It comes down to how thick your product is and how big your runs are. Our team will look at your setup and suggest the best motor.

Q: Can I add heating or cooling features to the tank?

A: Absolutely. You can choose heated jackets, chill coils, or sensors to keep the tank at the right temp for your work.

Q: Do you provide international shipping and installation support?

A: Yes, we ship anywhere and can walk your team through set-up online, or we can come out in person if you prefer.

Q: What certifications do your tanks have?

A: Every tank meets CE, ISO, and GMP rules. Let us know what you really need, and we will send the matching papers.