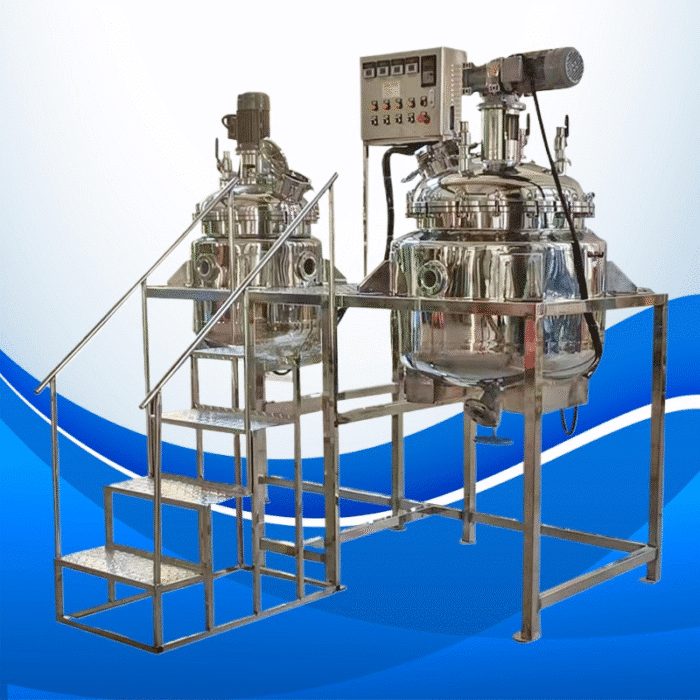

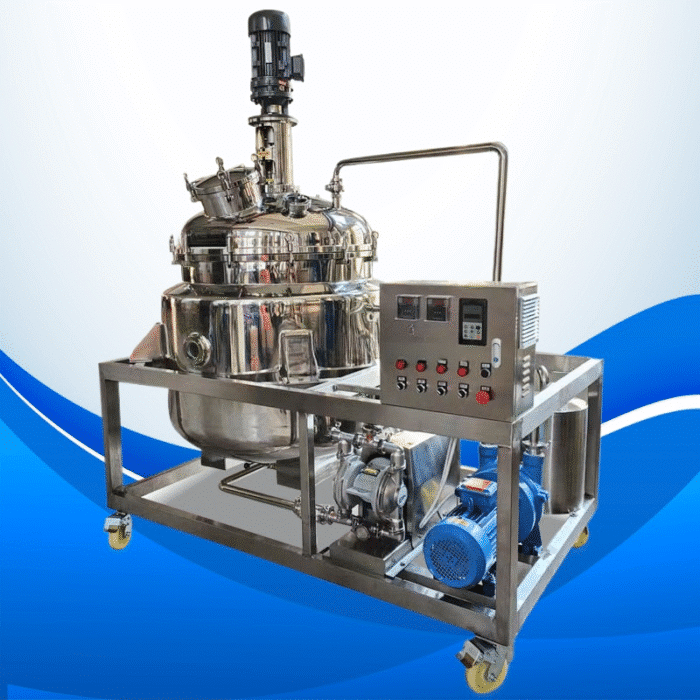

Premium Stainless Steel Reactors

- Capacity: 50 liters to 30,000 liters

- Mixer power: 1.5 kW to 55 kW

- Material: 304 or 316L

- Voltage: 110V to 600V

- Heating method: Electric or steam heating

- Layer:single/double jacket/three jacket

- Mixer types: Impeller-type, Anchor-type, Turbine-type, High-shear-type, Magnetic mixer, Anchor-type mixer with scrapers,dispersing

- Optional: platform, wheels, ladder,variable frequency drive,explosion-proof device

- Certificates: ASME, CE, GMP, UL, ATEX, ISO 9001

- Our equipment supports customisation, global delivery, and a 1-year warranty.

- If you have drawings, we can process them for you.

Note: Please contact our sales team before placing an order. Website prices are for reference only; specific pricing requires understanding your requirements to provide a quote.

Email:info@ace-chn.com

Tel: +86 186 2683 5909

WeChat: ace-chn

WhatsApp: +86 186 2683 5909

$5,400.00

Guaranteed Safe Checkout

Recommend RPM: 0-960RPM

Viscosity: Low/medium viscosity

Application: Mainly Liquid mixing

Recommend RPM: 0-200RPM

Viscosity: Low/medium viscosity

Application: Mainly Liquid mixing

Recommend RPM: 30RPM

Viscosity: Medium/High viscosity

Application: Melting, High viscosity product mixing, For single wall tank

Recommend RPM: 30RPM

Viscosity: Medium/High viscosity

Application: Melting, High viscosity product mixing, For jacket tank

Recommend RPM: 1480/2850 RPM

Viscosity: Low/medium viscosity

Application: Liquid powder mixing and dispersion

Recommend RPM: 1480/2850 RPM

Viscosity: Low/medium/High viscosity

Application: Liquid powder mixing and homogenizing

Recommend RPM: 0-355RPM

Viscosity: Low/medium viscosity

Application: Install at bottom, No mechanical seal working condition

Recommend RPM: As above

Viscosity: Low/medium viscosity

Application: Liquid powder mixing and dispersion For tank volume >300L

High-Performance Stainless Steel Reactors for Windows-Down Industries

When your business relies on precision, toughness, and total cleanliness, stainless steel reactors become your best friends. Built to mix, heat, cool, and drive chemical reactions in tightly controlled settings, these units fit right into pharma, chemicals, biotech, cosmetics, and food processing lines.

Picking the right stainless steel reactor maker is about more than just shiny steel; it’s about safety and getting the job done fast and right. This overview shows off our reactors, pointing to their rock-solid build, smart design options, and ability to tackle a wide range of jobs.

Why Our Stainless Steel Reactors Stand Out

We team up with trusted, seasoned reactor builders to give you tailor-made systems that fit your process like a glove. Here’s what you gain:

1. Top-Notch Material Options

- 304 Stainless Steel: Tough against rust and easy on the budget; best for everyday chemicals and food-grade uses.

- 316L Stainless Steel: Extra protection against salt and rough chemicals; great for pharma, biotech, and any marine job.

2. Broad Capacity Choices

Whether you’re running a tiny lab or a mega plant, our reactors can hold from 50 liters to 30,000 liters. This means you can test small batches, run medium jobs, or deliver huge production runs without missing a beat.

3. Custom Mixing Power

Getting the mix just right is what keeps everything on track. Our stainless steel reactors come with motors from 1.5 kW to 11 kW, so you can fine-tune the power to match how viscous the materials are and how tough the process is. Pick from impeller, anchor, paddle, or high-shear agitators to fit what you’re making.

4. Flexible Design Options

- You can go with jacketed or non-jacketed for heating or cooling;

- The vessels can handle pressure and vacuum;

- They’re clean-in-place and steam-in-place ready for sanitary needs;

- You can add glass sight ports, load cells, and automation hooks to suit your setup.

Where to Put These Reactors

Seeing the reactors in action helps you picture how they’ll perform:

- In pharma, they handle API synthesis, crystallization, and blending.

- In chemical processing, the corrosion-resistant tanks mix acids, bases, and solvents.

- For biotech, they sterilize gently for microbial or cell cultures.

- In cosmetics, they emulsify creams and lotions under vacuum.

- In food and beverage, they batch mix syrups and sauces, always with hygiene in mind.

Every one of these tasks needs top engineering and tough materials. That’s why our reactors tick all the boxes: ASME, GMP, and CE certifications, based on what regulations you’re working with.

Materials and Craftsmanship You Can Trust

Our stainless steel reactors are made with real care. You’ll notice the perfect welds and shiny mirror-polished surfaces, plus a sturdy built frame. Whether you’re working with strong acids, tiny proteins, or thick slurries, our reactors keep working right for years.

Why Industry Leaders Choose Our Reactors

- Super-long life in tough places

- Can be sized for a tiny lab or a giant factory

- Worldwide team ready to install and help out

- Fast turnaround and fair pricing for custom-builds

Ready to Order? Here’s What to Think About

We’re ready to help you pick the perfect setup for your job. Here’s what to check before you order:

- What size do you need (liters)?

- Should you pick 304 or 316L stainless?

- What kind of stirrer and motor power are you after?

- Do you need to handle pressure or vacuum?

- Will you need the jacket for heating or cooling?

Our team will guide you at every step, so your reactor fits right into your operation.

Frequently Asked Questions

Q1: How long does a custom stainless reactor take to make?

A: Usually, 3 to 6 weeks, based on how complex the design is and the size you need.

Q2: Can I hook these reactors right into an automated production line?

A: For sure! We’ve got PLC ports, sensor hook-ups, and remote monitoring options ready to go.

Q3: Are your reactors good to go for GMP and FDA?

A: Yep. We make sure all the docs and the way we build them meet GMP and FDA rules, just ask.

Q4: Can I switch from 304 to 316L halfway through?

A: You bet! Just do us a favor and nail down the material during design to save on cost and get it to you faster.