Premium Jacketed Liquid Mixing Tank for Industrial Use

- Capacity: 50 liters to 30,000 liters

- Mixer power: 1.5 kW to 55 kW

- Material: 304 or 316L

- Voltage: 110V to 600V

- Heating method: Electric or steam heating

- Layer:single/double jacket/three jacket

- Mixer types: Impeller-type, Anchor-type, Turbine-type, High-shear-type, Magnetic mixer, Anchor-type mixer with scrapers,dispersing

- Optional: platform, wheels, ladder,variable frequency drive,explosion-proof device

- Certificates: ASME, CE, GMP, UL, ATEX, ISO 9001

- Our equipment supports customisation, global delivery, and a 1-year warranty.

- If you have drawings, we can process them for you.

Note: Please contact our sales team before placing an order. Website prices are for reference only; specific pricing requires understanding your requirements to provide a quote.

Email:info@ace-chn.com

Tel: +86 186 2683 5909

WeChat: ace-chn

WhatsApp: +86 186 2683 5909

$3,480.00

Guaranteed Safe Checkout

Recommend RPM: 0-960RPM

Viscosity: Low/medium viscosity

Application: Mainly Liquid mixing

Recommend RPM: 0-200RPM

Viscosity: Low/medium viscosity

Application: Mainly Liquid mixing

Recommend RPM: 30RPM

Viscosity: Medium/High viscosity

Application: Melting, High viscosity product mixing, For single wall tank

Recommend RPM: 30RPM

Viscosity: Medium/High viscosity

Application: Melting, High viscosity product mixing, For jacket tank

Recommend RPM: 1480/2850 RPM

Viscosity: Low/medium viscosity

Application: Liquid powder mixing and dispersion

Recommend RPM: 1480/2850 RPM

Viscosity: Low/medium/High viscosity

Application: Liquid powder mixing and homogenizing

Recommend RPM: 0-355RPM

Viscosity: Low/medium viscosity

Application: Install at bottom, No mechanical seal working condition

Recommend RPM: As above

Viscosity: Low/medium viscosity

Application: Liquid powder mixing and dispersion For tank volume >300L

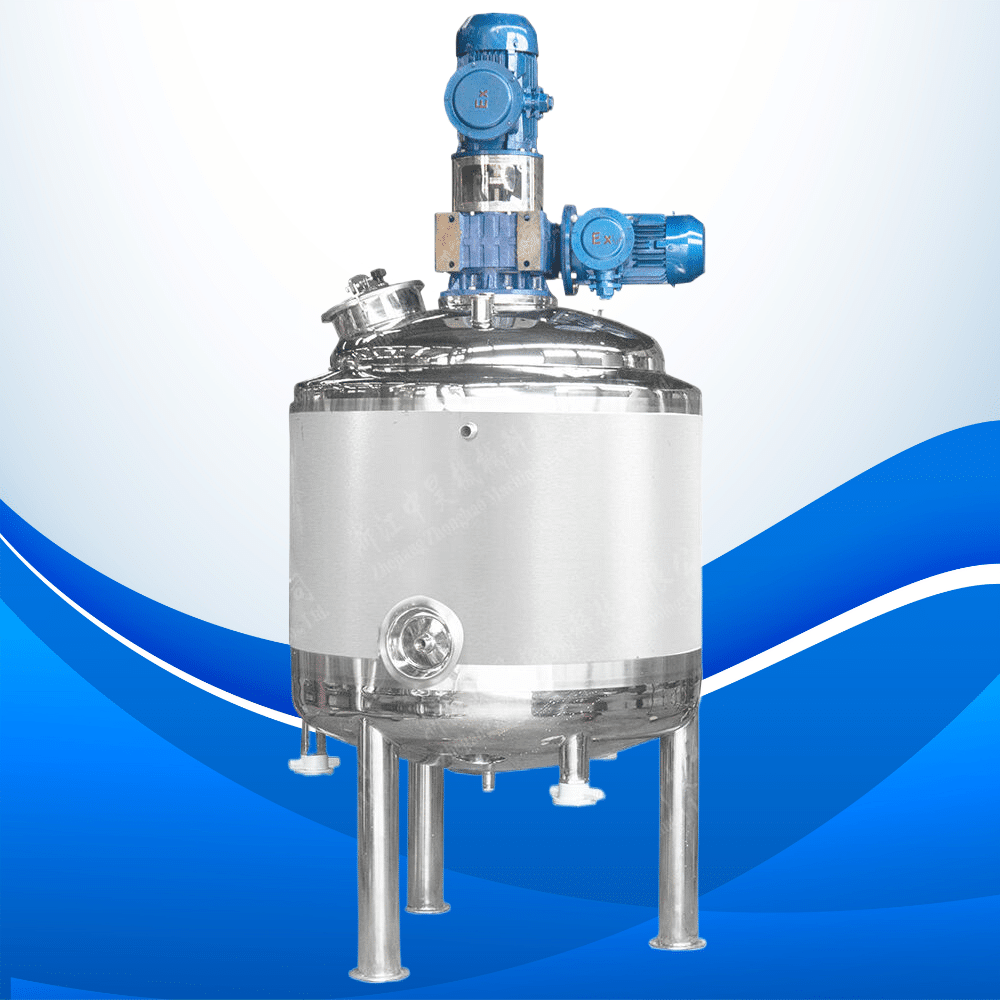

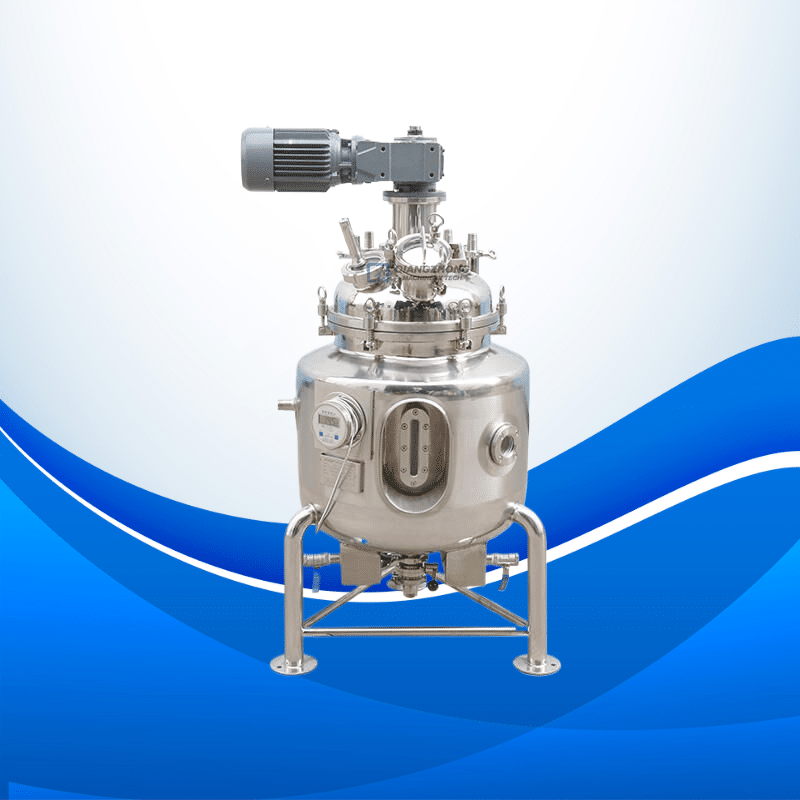

Product Description: Jacketed Liquid Mixing Tank

Overview

Built for tough jobs, our jacketed liquid mixing tank blends, heats, and cools liquids with speed and accuracy. Heavy-duty materials, plus options you can tweak, mean it keeps working hard in factories that make medicines, drinks, beauty products, and chemicals.

Emulsifying, homogenizing, or simply warming fluids? This tank spreads heat evenly and mixes fast, so every batch is the same quality and your line can grow without surprises.

🔧 Key Features and Tech Specs

- Housing Material: Choose between 304 stainless steel for general use or tougher 316L stainless steel if you expect heavy corrosion.

- Heater Power: Starts at 1.5 kilowatts and can go up to 55 kilowatts, so you can size it exactly to what your process needs.

- Voltage: Works with just about any supply-110, 220, 380, 440, and even 600 volts.

- Tank Size: Ranges from a small 50 liters all the way up to 30,000 liters.

- Mixer Type: Comes with a mechanical stirrer; pick anchor, paddle, or turbine blade depending on how thick your mix is.

- Temp Control: Jacketed vessel lets you heat or cool using steam, water, or oil that flows in and out.

- Electronics: Optional digital PLC screen automates run times, speeds, and alarms.

- Seal Choice: Select between a mechanical seal or a magnet-driven seal to keep the inside clean.

🏭 Where You’ll Find It Working

- Pharma Plants

Make even blends of liquid meds, mix active powders, or whip up thick gels while keeping the room sterile and the temp just right. - Food Lines

Works well with syrups, dairy, sauces, and drinks that need gentle heat or chill during mixing. Food-grade steel keeps everything clean. - Beauty Factories

Stir lotions, creams, shampoos, and serums without lumps. The jacketed wall holds the right heat for a smooth finish. - Chemical Labs

Control reactions or dissolve solids at a steady temp and speed, reducing risks and making every batch reliable.

⚙️ Why Pick Our Jacketed Liquid Mixing Tank?

- ✅ Steady Heat and Cool: The twin-wall jacket spreads heat or chill evenly, stopping hot or cold spots.

- ✅ Tough and Clean: 316L or 304 stainless steel resists rust and meets GMP and FDA rules.

- ✅ Flexible Power Options: From a 1.5kW 110V bench unit to a big 55kW 600V system, we’ve got you covered.

- ✅ Grow with Your Batch Sizes: Tank works great for small pilot runs or huge production lines.

- ✅ Easy to Keep Clean: Built-in CIP and SIP setup lets you sanitize the tank with little fuss.

📦 Customizing and Ordering

Every tank is made to fit your process. You choose power, voltage, size, mixer style, and materials. Our engineers are ready to tweak the design, plan the install, and help on-site too.

Get in touch today for a quick quote or to hatch a solution built just for you!

❓ Frequently Asked Questions (FAQ)

Q1: Can I use this tank for both heating and cooling?

Yep. The jacket takes steam for heating or works with chilled water and oil to cool.

Q2: Is the tank suitable for high-viscosity fluids?

Absolutely. We offer mixer designs made for anything from watery drinks to thick gels.

Q3: How long does delivery take?

Standard lead time is 2 to 4 weeks. Need it faster? Expedited production is available.

Q4: Do you ship outside the US and adjust the volts for different places?

Yep, we ship anywhere you need, and we set the voltage to work with your local power.

Q5: Can I order my tank with a digital control system?

You sure can. We offer a PLC touch-screen panel that lets you dial in temp, speed, and other steps automatically.

🛒 Ready to lift your production to the next level?

Get a jacketed mixing tank that gives you power, dependability, and keeps you in line with rules. This tank fits an upgrade project or a brand-new line you’re rolling out.

👉 Reach out today for a quick chat and a price that matches your needs. Together, we’ll put together the perfect mixing setup for you.