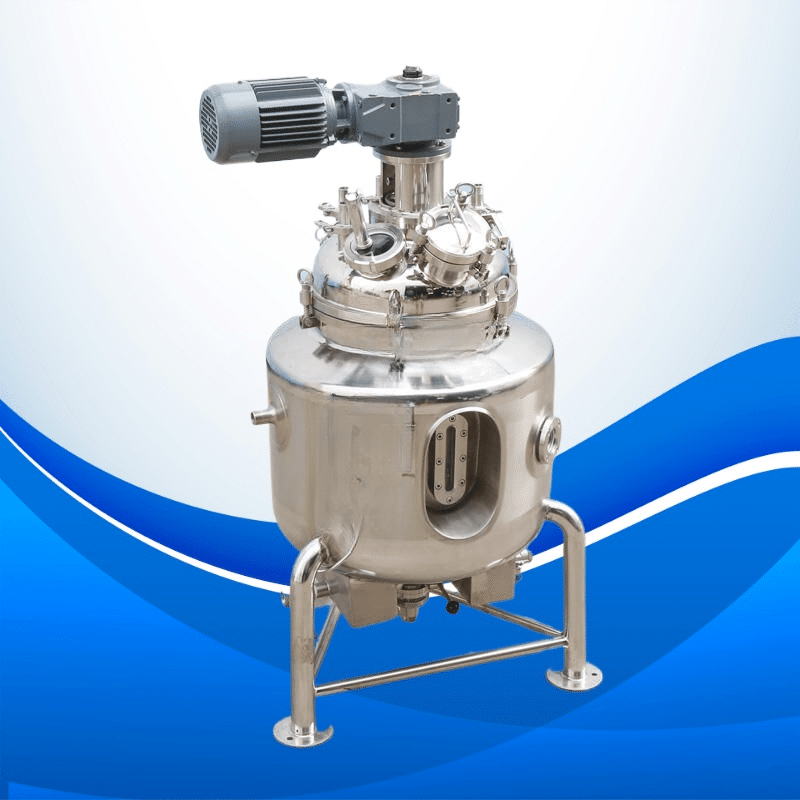

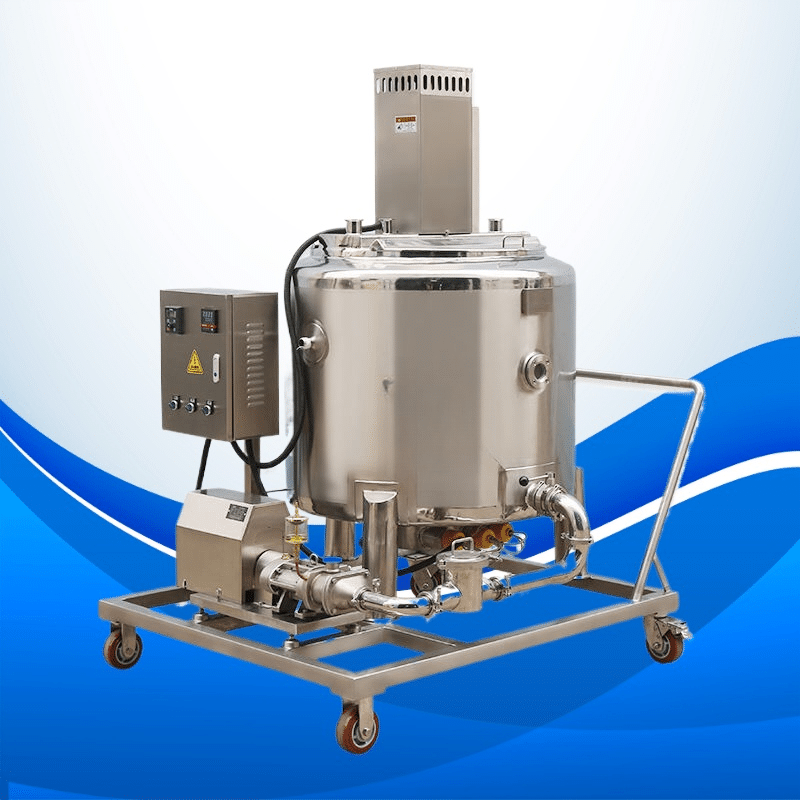

Premium Insulating Mixing Tank

- Capacity: 50 liters to 30,000 liters

- Mixer power: 1.5 kW to 55 kW

- Material: 304 or 316L

- Voltage: 110V to 600V

- Heating method: Electric or steam heating

- Layer:single/double jacket/three jacket

- Mixer types: Impeller-type, Anchor-type, Turbine-type, High-shear-type, Magnetic mixer, Anchor-type mixer with scrapers,dispersing

- Optional: platform, wheels, ladder,variable frequency drive,explosion-proof device

- Certificates: ASME, CE, GMP, UL, ATEX, ISO 9001

- Our equipment supports customisation, global delivery, and a 1-year warranty.

- If you have drawings, we can process them for you.

Note: Please contact our sales team before placing an order. Website prices are for reference only; specific pricing requires understanding your requirements to provide a quote.

Email:info@ace-chn.com

Tel: +86 186 2683 5909

WeChat: ace-chn

WhatsApp: +86 186 2683 5909

$3,405.00

Guaranteed Safe Checkout

Recommend RPM: 0-960RPM

Viscosity: Low/medium viscosity

Application: Mainly Liquid mixing

Recommend RPM: 0-200RPM

Viscosity: Low/medium viscosity

Application: Mainly Liquid mixing

Recommend RPM: 30RPM

Viscosity: Medium/High viscosity

Application: Melting, High viscosity product mixing, For single wall tank

Recommend RPM: 30RPM

Viscosity: Medium/High viscosity

Application: Melting, High viscosity product mixing, For jacket tank

Recommend RPM: 1480/2850 RPM

Viscosity: Low/medium viscosity

Application: Liquid powder mixing and dispersion

Recommend RPM: 1480/2850 RPM

Viscosity: Low/medium/High viscosity

Application: Liquid powder mixing and homogenizing

Recommend RPM: 0-355RPM

Viscosity: Low/medium viscosity

Application: Install at bottom, No mechanical seal working condition

Recommend RPM: As above

Viscosity: Low/medium viscosity

Application: Liquid powder mixing and dispersion For tank volume >300L

When you need a tank that stays on target, saves power, and won’t crack under pressure, our insulated mixing unit has you covered. Built for everyone from dairy plants to drug manufacturers, it keeps heat steady, stirs evenly, and gives every batch the same top-notch look and feel.

✔️ Why You’ll Love It

Thick, Lock-In Insulation

Heavy-duty foam walls cut out outside heat or chill, so recipes stay put, power bills drop, and operators handle the tank without a burn.

Plug-and-Play Volt Range

Select 110V, 230V, or all the way up to 600V, plus watt ratings from 1.5 kW to 55 kW, and it slips cleanly into your plant’s grid.

Top-Grade Stainless Steel

Pick shiny 316L for salt-water work or 304 for most other jobs, giving food, pharma, or chemical lines the rust-proof shell they need.

Dead-Zone Free Blending

Tuned paddles whip every corner of the tank, so suspensions, emulsions, and thick pastes come out smooth every time.

🛠️ Where People Use It Every Day

Dairy & Beverage Lines

Pasteurize and mix milk, cream, juices, or sweet syrups at the right temp. Steady heat stops spoilage and locks in fresh taste.

Drug & Cosmetic Labs

Blend creams, serums, or gels under clean-room rules. The sealed steel and thick wrap keep actives strong till the lid goes on.

Chemical Processing

Mix solvents, glues, resins, or special chemicals evenly while keeping heat under control and limiting runaway reactions.

- Handy Discharge Openings, No Dead Zones — Exit side ports located at bottom sill to ensure low residual material removal.

- Traceable Materials — Test results from accredited labs support ingredient certificates and lot settlement records.

R&D & Pilot Plants

Variable voltage settings let you run lab batches or scale up to full production without swapping gear-nothing is lost in the move.

- Compact Build — Footprint maximizes under-roof room yet retains heavy-duty strength for future expansion plans.

- Castor Friable Base — heavy swivel wheels permit quick site moves and anchored locking for stationary operation.

📊 Technical Specifications

| Features | Options & Details |

|---|---|

| Voltage | 110–600 V, single or three-phase; explosion-proof grades on request |

| Power Rating | 1.5 kW to 55 kW, stepped and easy-to-read gauges |

| Materials Available | 316L or 304 stainless steel, pickled and passivated |

| Insulation | 4 /3 EGT high-performance foam with SS protection |

| Agitator Designs | Anchor, turbine, or high-shear mix heads |

| Capacity Options | from 100 L pilot sizes to 10,000 L industrial vessels |

| Control Features | Manual, PLC, or smart-panel with IoT signal |

🔧 Configurable to Your Needs

- Choose tank volume, mixer type, insulation thickness, and finish—mirror-polish, sanitary, bead blasted, or brushed.

- Add process extras: electric heaters, chiller jackets, CIP nozzles, sight windows, or special sampling ports.

- Electrical features blend voltage, phase, and NEMA grading suited for your plant or zone.

Frequently Asked Questions (FAQ)

Q: What determines the choice between 316L and 304 stainless steel?

A: If your work includes acids, salts, or strict hygiene rules—say pharmaceuticals or food-quality control—316L is best. For mild applications like paint, oil, or chemical pre-mix, 304 provides reliable, cost-effective service.

Q: Can I hook this tank up to my automated line?

A: You bet. It comes with optional PLC or SCADA ports and standard fittings so the wires snap right in.

Q: How quick does the tank hit the target temp?

A: That mostly depends on the insulation, jacket layout, and heater size you pick. With a 55 kW unit and good insulation, temps move fast without burning extra power.

Q: Can you build a tank in a non-standard size?

A: For sure! We do everything from small lab vessels to giant floor-mounted tanks. Just send your specs, and we’ll whip up a design that works.

🔔 Ready to Order or Customize?

Boost your output and cut waste—order a made-to-fit insulating mixing tank today. Talk to sales now about:

- ✔️ Material grade (316L or 304)

- ✔️ Electrical config (110-600 V)

- ✔️ Mixing set-up (agitator, insulation)

- ✔️ Extras (CIP, controls, finish)

Get peak performance with less downtime. Choose our heavy-duty insulating mixing tank and enjoy dependable processing every shift.