Premium High Shear Emulsifiers for Industrial mixer

- Material: 304 or 316L

- Voltage: 110V 208V 220V 380V 400V 415V 480V 600V

- Certificates: CE, GMP, UL, ATEX, ISO 9001

- Power:0.75KW-55KW (1 HP – 74 HP)

- Motor brands: ABB, Chinese brands, SEW, Siemens (optional)

- 1-year free warranty with door-to-door delivery.

- We have it in stock.

- MADE IN CHINA

Please contact our sales team before placing your order.

Email:info@ace-chn.com

Tel:+86 18626835909

WeChat: ace-chn

$850.00

Guaranteed Safe Checkout

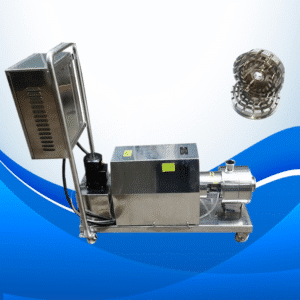

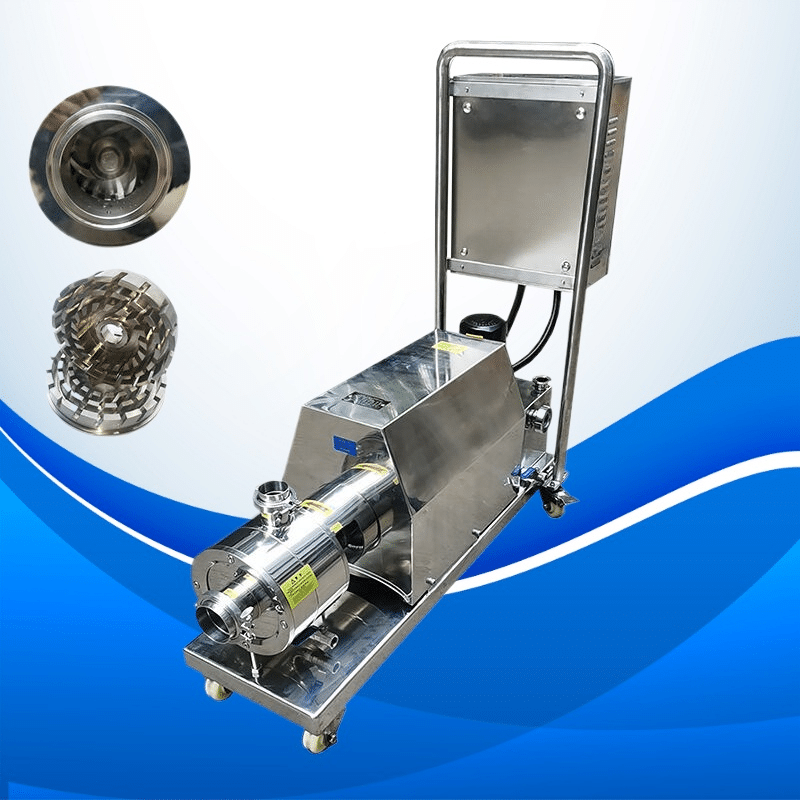

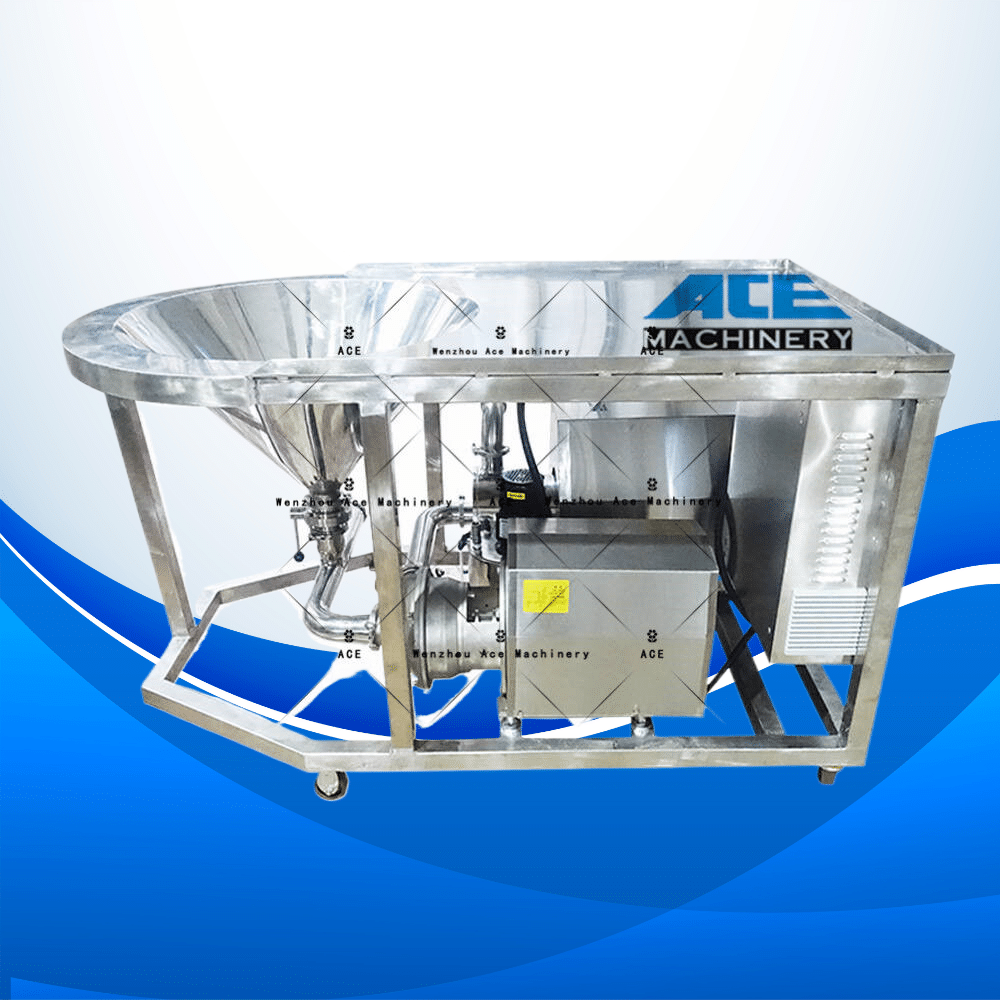

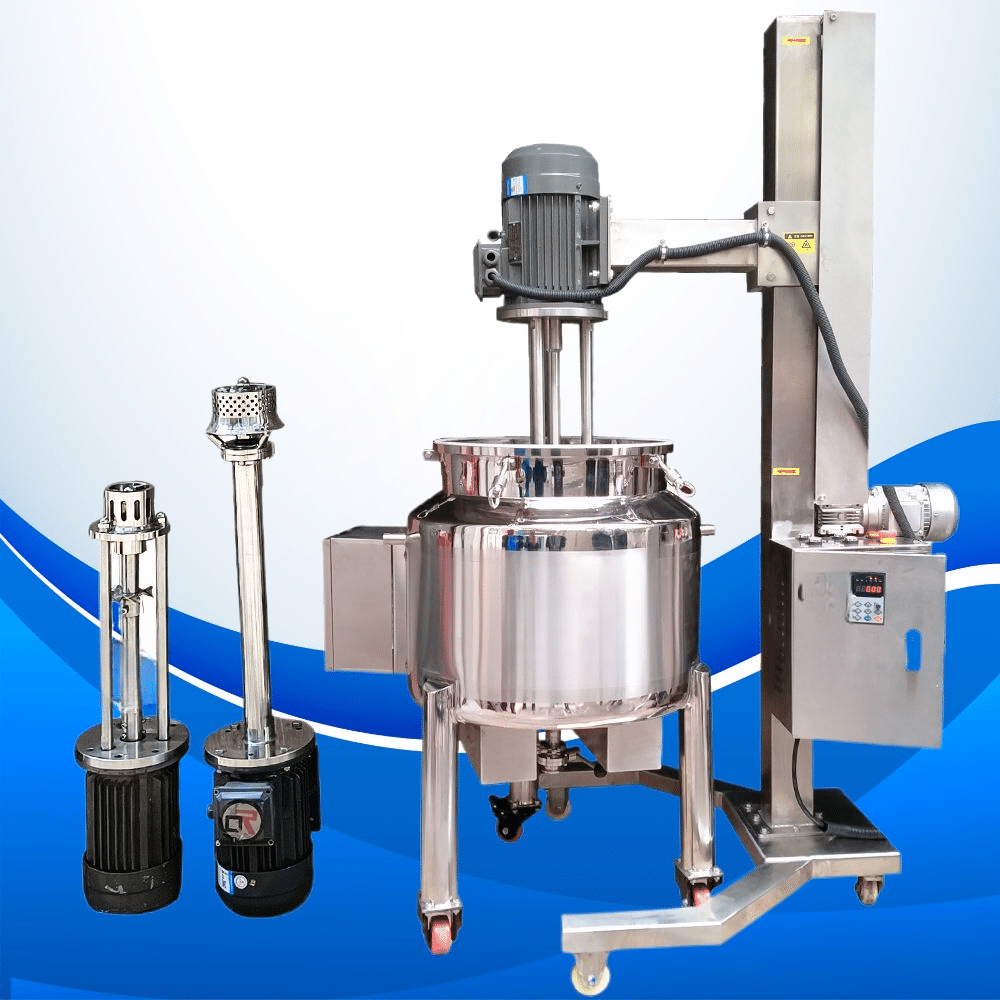

We manufacture and sell the following types of mixers

Mix, emulsify, homogenize, disintegrate and dissolve

Ideal for disintegrating solids and incorporating powders

Reduce mixing times by up to 80%

Reduce mixing times by up to 90%

Quickly disperse and hydrate powders, even at higher viscosities

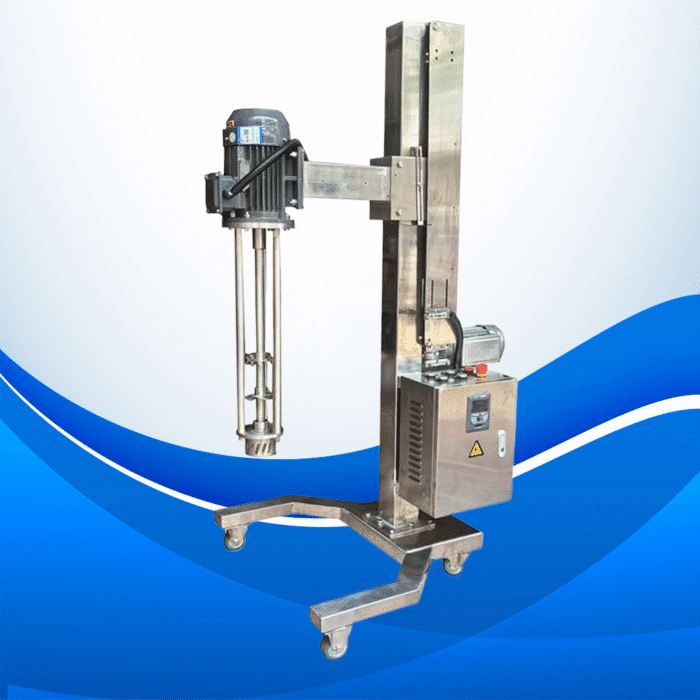

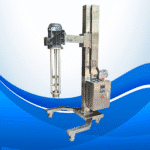

Easy to move and lift

Features heating, cooling, vacuum, and other functions

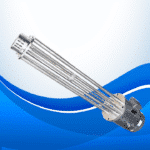

Recommended RPM: 1480/2850 RPM

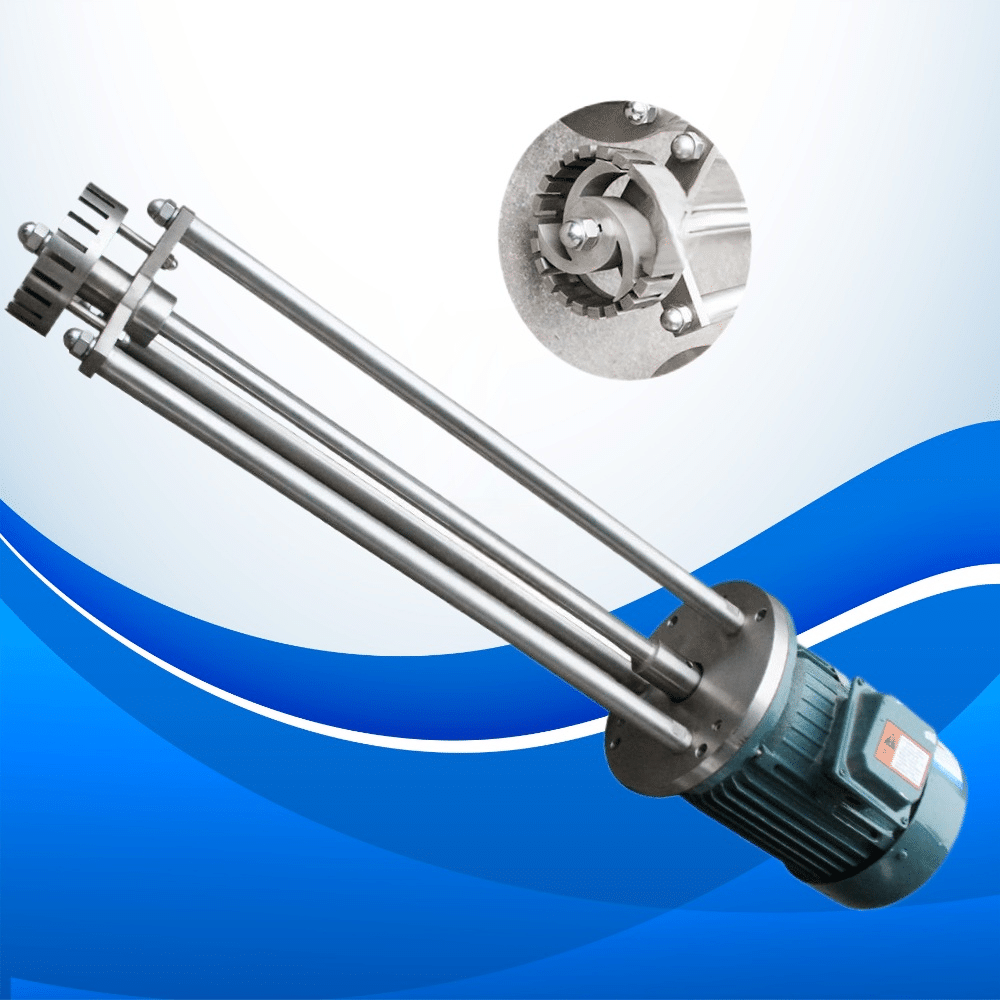

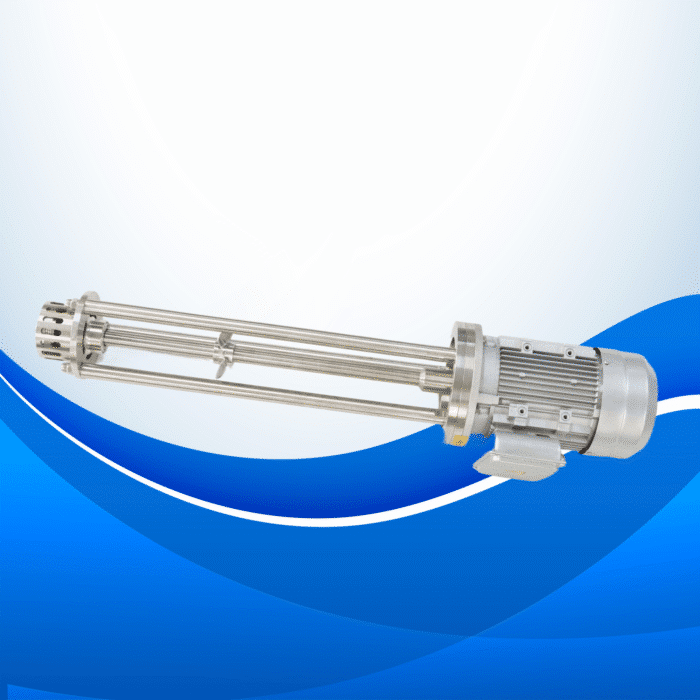

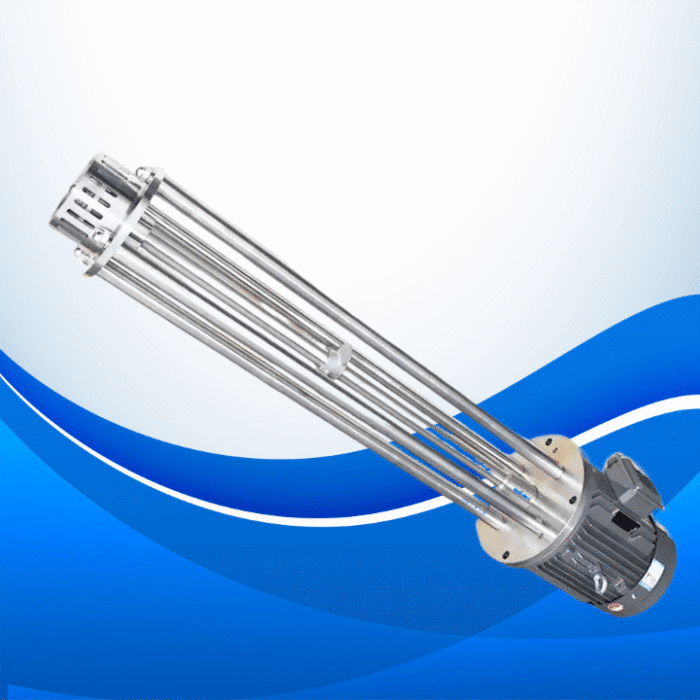

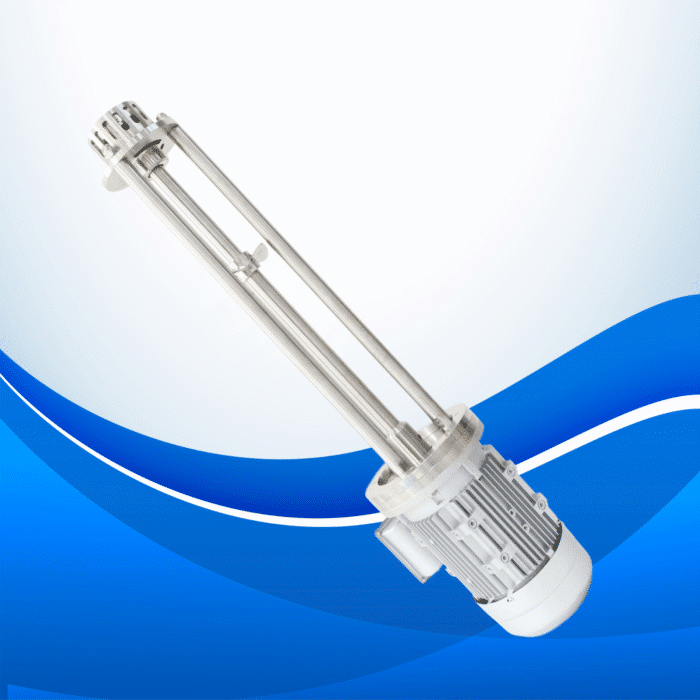

Product Description: High Shear Emulsifier

When you need a mixer you can trust day-in and day-out, our high-shear emulsifiers step up. Built for tough plant floors, they whip together ingredients so smoothly that batch after batch looks and feels the same. From meds to lotions, sauces to specialty chemicals, these machines keep your line moving and your end product exactly as promised.

Key Advantages

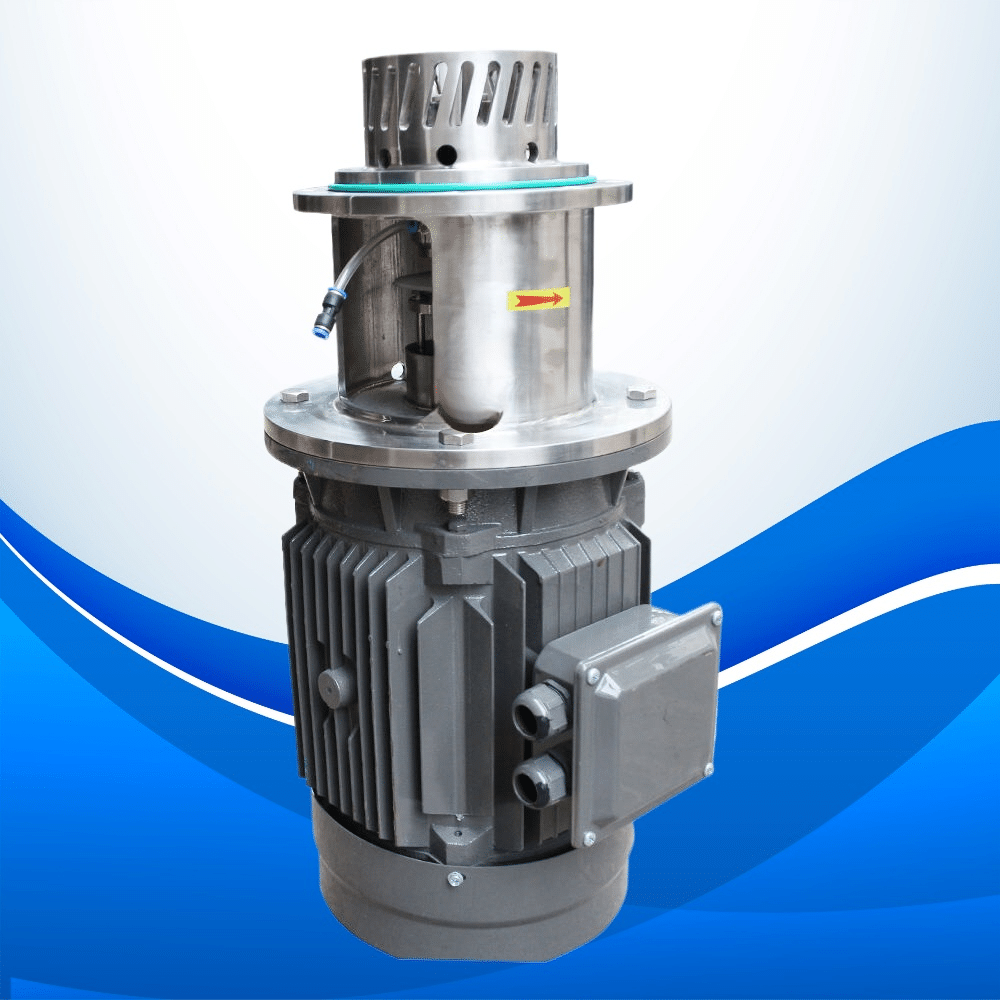

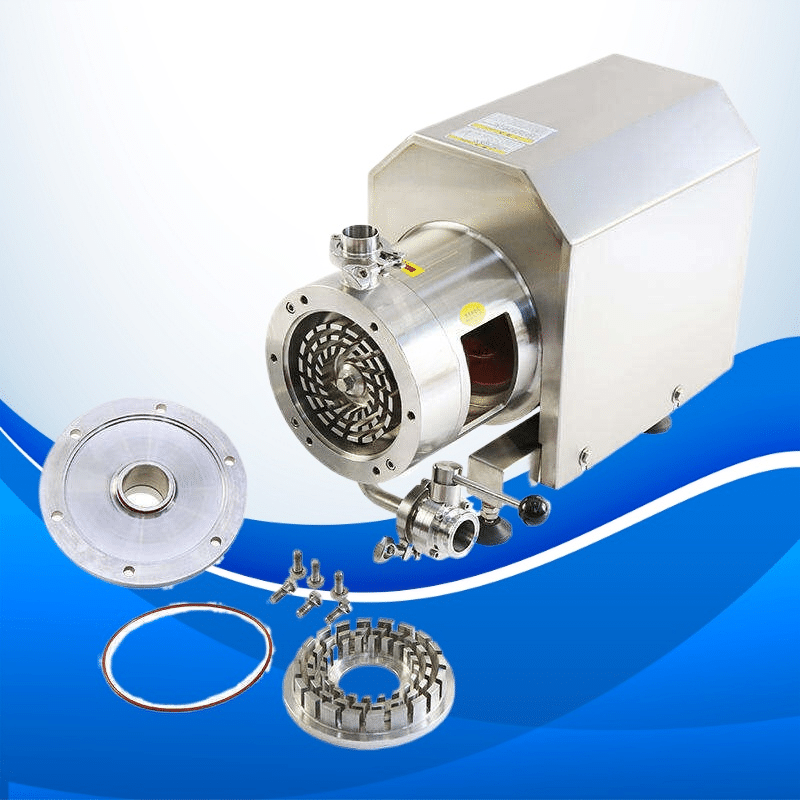

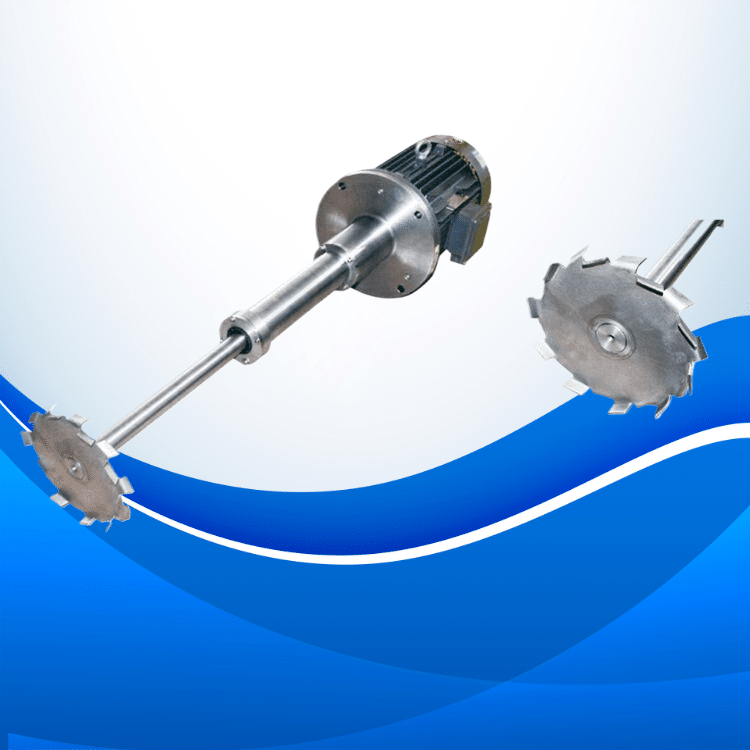

Smooth Particle Break-Up

The fast-moving rotor and stator stack hits each droplet with heavy hydraulic shear, smashing clumps and blending them evenly.

Power for Every Batch

Pick from 1.5-kilowatt benches for hobby-scale work all the way up to 35 kilowatts that keep giant tanks fed nonstop.

Worldwide Volt Options

Whether your outlet runs at 110 or 600 volts, we can set the machine to suit your region and save you headaches on startup.

Premium Metal Choices

Go with rugged 316L stainless if corrosion is a worry, or 304 stainless when everyday durability is all you need.

Service-Friendly Build

Bolted seals and removable heads mean you spend minutes—not days—on maintenance, so production stays high and costs stay low.

Application Scenarios

Picture your line moving faster and yielding less scrap while customers rave about product quality:

Cosmetic Manufacturing

Mix creams, gels, and serums to a silky finish—no lumps or watery layers.

Pharmaceuticals

Create uniform suspensions that meet all safety tests and help shelves stay stocked.

Food & Beverage

Blend dressings, milks, or smoothies and keep flavor and nutrition right where they belong.

Chemical Processing

Spread out colorants, resins, and other ingredients evenly, so the finished product performs better.

Whether you’re making lotion, paint, or a specialty cleaner, our high-shear mixer gives you the same silky finish batch after batch.

Customization & Technical Specifications

Feature Options

- Power Output: 1.5 kW – 35 kW

- Voltage Support: 110 V – 600 V

- Material Selection: 316L / 304 stainless steel

- Rotor-stator speed: Up to 3000 rpm

- Viscosity range: Up to 50,000 cps

Unsure which version fits best? Talk to our tech team, or let us build a unit that matches your line speed, ingredient thickness, and space.

Reach Out for Your Quote or Custom Setup

Ready to step up your mixing game? Our high-shear emulsifiers can help, whether you’re swapping old gear or starting an entirely new line.

Email or call us for a free chat and quick quote. We also offer fast shipping, OEM spare parts, and worldwide delivery.

FAQs

Q: What’s the difference between 304 and 316L stainless steel?

A: 316L stands up to salt and acid better, so it’s the go-to for food and drug work; 304 costs less and works well in most other places.

Q: How do I find the right power level for my batch?

A: It really comes down to how big your batch is, how thick the mix feels, and how fast you want it to move. Our engineers love helping you nail those numbers.

Q: Can your emulsifier break down thick products?

A: Absolutely! We have setups that handle materials up to 50,000 cps with ease.

Q: Do you ship outside the U.S.?

A: You bet. We deliver everywhere and can adjust voltage to match local standards.