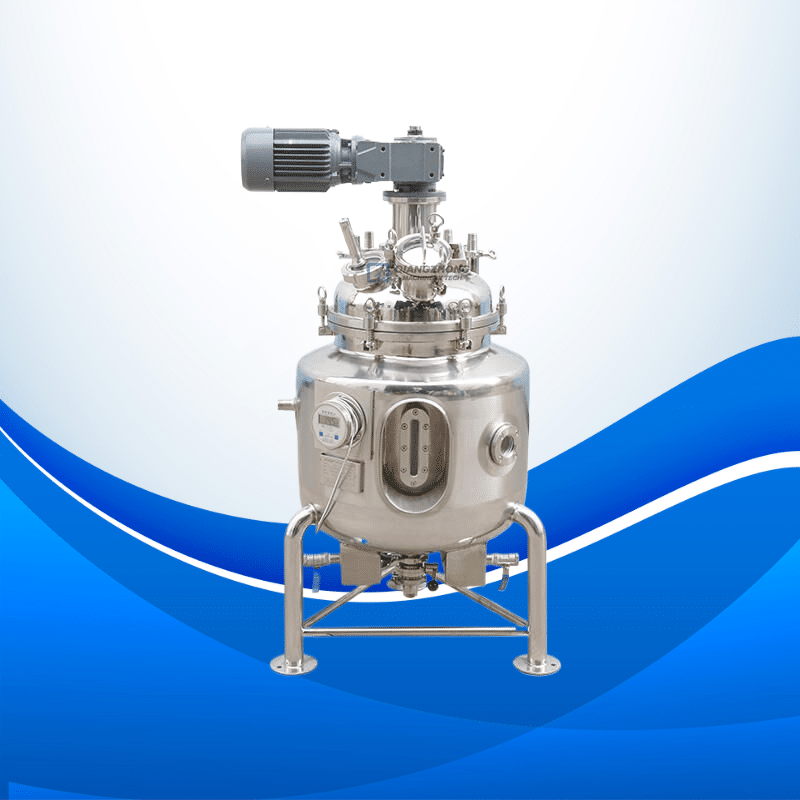

Premium Food Grade Mixing Tanks

- Capacity: 50 liters to 30,000 liters

- Mixer power: 1.5 kW to 55 kW

- Material: 304 or 316L

- Voltage: 110V to 600V

- Heating method: Electric or steam heating

- Layer:single/double jacket/three jacket

- Mixer types: Impeller-type, Anchor-type, Turbine-type, High-shear-type, Magnetic mixer, Anchor-type mixer with scrapers,dispersing

- Optional: platform, wheels, ladder,variable frequency drive,explosion-proof device

- Certificates: ASME, CE, GMP, UL, ATEX, ISO 9001

- Our equipment supports customisation, global delivery, and a 1-year warranty.

- If you have drawings, we can process them for you.

Note: Please contact our sales team before placing an order. Website prices are for reference only; specific pricing requires understanding your requirements to provide a quote.

Email:info@ace-chn.com

Tel: +86 186 2683 5909

WeChat: ace-chn

WhatsApp: +86 186 2683 5909

$4,500.00

Guaranteed Safe Checkout

Recommend RPM: 0-960RPM

Viscosity: Low/medium viscosity

Application: Mainly Liquid mixing

Recommend RPM: 0-200RPM

Viscosity: Low/medium viscosity

Application: Mainly Liquid mixing

Recommend RPM: 30RPM

Viscosity: Medium/High viscosity

Application: Melting, High viscosity product mixing, For single wall tank

Recommend RPM: 30RPM

Viscosity: Medium/High viscosity

Application: Melting, High viscosity product mixing, For jacket tank

Recommend RPM: 1480/2850 RPM

Viscosity: Low/medium viscosity

Application: Liquid powder mixing and dispersion

Recommend RPM: 1480/2850 RPM

Viscosity: Low/medium/High viscosity

Application: Liquid powder mixing and homogenizing

Recommend RPM: 0-355RPM

Viscosity: Low/medium viscosity

Application: Install at bottom, No mechanical seal working condition

Recommend RPM: As above

Viscosity: Low/medium viscosity

Application: Liquid powder mixing and dispersion For tank volume >300L

Product Description: Food Grade Mixing Tank

When you’re working in food and drink, every detail counts. That’s why serious producers use equipment that mixes ingredients perfectly while playing by strict safety rules. Our food-grade mixing tank does just that, quietly blending your product without letting germs get a chance. It’s also built to fit many jobs-from soft drink lines to dairy plants and even cosmetic labs-with power, voltage, and materials that you get to pick.

Key Features & Benefits

Tough Stainless Steel: 316L & 304

Every tank leaves the shop made from either 316L or 304 stainless steel, so you never worry about rust or stains. The 316L grade laughs in the face of rough chemicals and high heat, making it the workhorse in heavy-duty kitchens. The 304 version is nearly as tough and takes care of most everyday food jobs with ease.

Pick Your Power and Voltage

Because no two plants run the same way, we give you choice, not one-size-fits-all: Power range runs from a modest 1.5KW up to 55KW, so you can match the tank to how fast you need to fill jars or bottles.

Voltage Choices

You can pick a voltage between 110V and 600V, so the tank will match the electrical setup where you work or the gear you plan to run.

Clean and Hygienic

Keeping food safe starts with clean equipment. Our food-grade mixing tanks have smooth walls that wipe down easily, stopping dirt from moving around. They meet all the food-safety rules, so your line stays in the clear with health inspectors.

Works Everywhere

Because the tanks are built to food-grade specs, they fit a bunch of jobs:

- Beverage making: Mix up juices, sodas, or even cocktails.

- Dairy work: Blend milk, yogurt, cream, and other dairy items.

- Bakery goods: From cake batter to icing, they stir both dry and wet parts together fast.

- Sauces and dips: Whip up dressings, BBQ sauces, or any condiment you sell.

- Cosmetics and meds: You can also use them for skin creams or liquid drugs.

Saves Power

Every tank is built to use power wisely; that way your bills stay lower, and you get more done in less time. With adjustable settings, you can dial in just the right level of power for each batch you make.

Customization and Ordering

Every production line has its own quirks, so we give you the chance to tweak our food-grade mixing tank until it fits yours perfectly. Need a certain size, a special paddle design, or something completely one-of-a-kind? Our team is ready to jump in and make it happen.

Shoot us a message today for a no-obligation quote or just to chat about what you have in mind. Our engineers will walk you through the options and help you build the best mixing tank for your operation.

Why Choose Our Food Grade Mixing Tank?

- Precision Engineering: Gives even, steady mixing, batch after batch.

- Customization Options: Whatever your workflow needs, we can adjust.

- Durability & Safety: Tough enough to last and meets all food-safety rules.

- Wide Range of Applications: Works great in almost every food plant.

FAQs

What is the difference between 316L and 304 stainless steel?

316L holds up better against rust and harsh cleaners, so it’s the go-to for tough environments. 304 is still solid for most food jobs but lea rather vulnerable to really aggressive chemicals.

FAQ Section:

What size food-grade mixing tank do I need?

How big of a thank you should get really depends on how much you plan to mix. We stock everything from tiny benches used by bakeries, all the way up to industrial drums that fill containers. Let our crew know your usual batch size, and we’ll help you pick one that fits.

Can I use this tank for both dry and liquid ingredients?

For sure. Each unit comes with a flexible stirring set-up designed to blend powders, gels, and even chunky mixes. You won’t have to swap equipment, so time wasted cleaning a separate tub is cut way back.

Are the tanks easy to clean?

Yes, cleaning downtime is almost zero. We polish every surface to a mirror finish and use no hidden seams, so soap and water glide over quickly. Plus, every model meets the latest food-safe guidelines, keeping your line spotlessly hygienic.

Call to Action

Ready for a food-grade mixing tank that works hard, looks good, and stays rust-free? Reach out today for a quote based on your recipe, room size, and budget. With options like adjustable blades, mobile carts, and quick-release lids, we build exactly what you need.

Don’t put it off, order your custom mixing tank now and move your production forward!