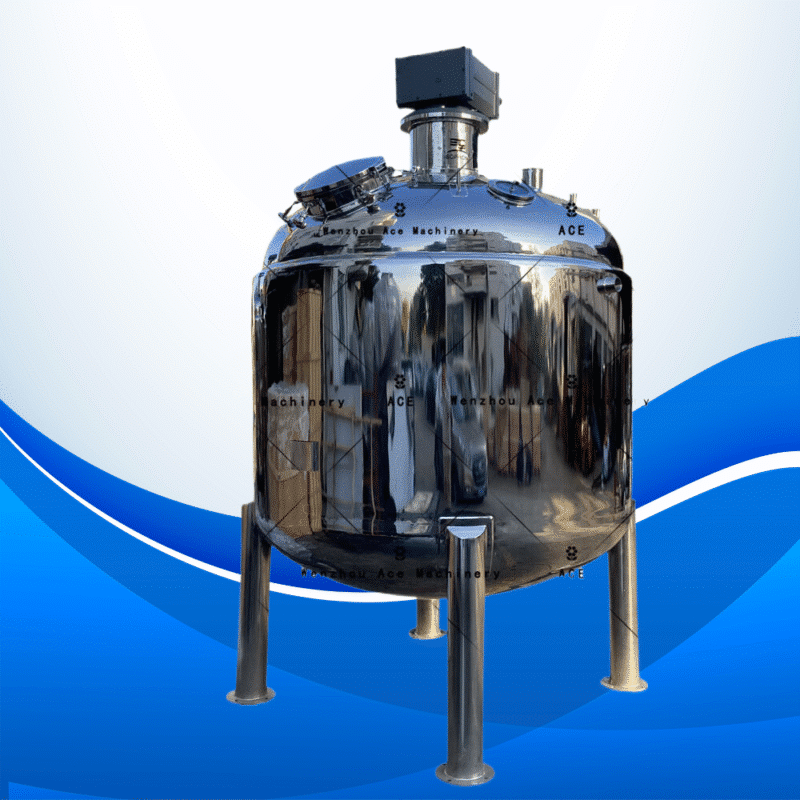

Premium Drink Mixing Tank for Efficient Beverage Production

- Capacity: 50 liters to 30,000 liters

- Mixer power: 1.5 kW to 55 kW

- Material: 304 or 316L

- Voltage: 110V to 600V

- Heating method: Electric or steam heating

- Layer:single/double jacket/three jacket

- Mixer types: Impeller-type, Anchor-type, Turbine-type, High-shear-type, Magnetic mixer, Anchor-type mixer with scrapers,dispersing

- Optional: platform, wheels, ladder,variable frequency drive,explosion-proof device

- Certificates: ASME, CE, GMP, UL, ATEX, ISO 9001

- Our equipment supports customisation, global delivery, and a 1-year warranty.

- If you have drawings, we can process them for you.

Note: Please contact our sales team before placing an order. Website prices are for reference only; specific pricing requires understanding your requirements to provide a quote.

Email:info@ace-chn.com

Tel: +86 186 2683 5909

WeChat: ace-chn

WhatsApp: +86 186 2683 5909

$4,100.00

Guaranteed Safe Checkout

Recommend RPM: 0-960RPM

Viscosity: Low/medium viscosity

Application: Mainly Liquid mixing

Recommend RPM: 0-200RPM

Viscosity: Low/medium viscosity

Application: Mainly Liquid mixing

Recommend RPM: 30RPM

Viscosity: Medium/High viscosity

Application: Melting, High viscosity product mixing, For single wall tank

Recommend RPM: 30RPM

Viscosity: Medium/High viscosity

Application: Melting, High viscosity product mixing, For jacket tank

Recommend RPM: 1480/2850 RPM

Viscosity: Low/medium viscosity

Application: Liquid powder mixing and dispersion

Recommend RPM: 1480/2850 RPM

Viscosity: Low/medium/High viscosity

Application: Liquid powder mixing and homogenizing

Recommend RPM: 0-355RPM

Viscosity: Low/medium viscosity

Application: Install at bottom, No mechanical seal working condition

Recommend RPM: As above

Viscosity: Low/medium viscosity

Application: Liquid powder mixing and dispersion For tank volume >300L

Looking to step up your drink-making game? Our heavy-duty mixing tank could be just what you need. Built for quick clean-up, steady operation, and a long list of uses, it works well in cafés, wedding caterers, craft breweries, small dairies, and juice houses.

Big Features That Matter

Built-to-Order Power

Pick any voltage from 110V house current to 600V industrial supply, and choose motors from 1.5 kW for a corner deli up to 55 kW for bottling plants.

Pro-Grade Metals

Go with food-safe 316L steel for maximum rust resistance, or more budget-friendly 304 steel that still holds up in busy kitchens.

Smooth Mixing

Variable-speed paddles, exact temp readouts, and optional heating-or-cooling jackets give you the blend you want without hot or cold spots.

Tidy and Quick to Clean

Polished walls, clip-on sanitary valves, full CIP plumbing, and airtight seals keep dirt out and cut clean time to a minimum.

Safe by Design

Every tank meets food plant codes and ships with pressure sensors, safety vents, and optional explosion-proof electric parts when needed.

Where It Works Best

Drinks Production Lines

Combine syrups, powders, color, and flavor with steady heat and gentle stir in one vessel. Perfect source for soft drinks, energy shots, and fresh fruit juices.

Craft Breweries & Distilleries

Use it to mix mash or wort on brew day. The 316L stainless keeps the taste pure, and the big power range lets you scale up or down for every batch.

Dairy & Nutraceutical Operations

Speed up the pasteurization of milk blends, protein shakes, or vitamin waters, keeping texture smooth and stopping any layer from floating.

Catering & Food Service

Turn small kitchens into production hubs for smoothies, sauces, and soups, cutting mixing time and needing almost no extra upkeep.

📊 Specs at a Glance

| Feature | Options |

|---|---|

| Voltage | 110 V, 220 V, 380 V, 480 V, 600 V |

| Power | 1.5 kW – 55 kW |

| Material | 316L or 304 stainless steel |

| Capacity | 100 L – 5000 L, built to order |

| Agitator Type | anchor, paddle, or turbine, speed adjustable |

| Temp Control | PID jacket for heating or cooling |

| Cleanability | CIP setup, tri-clamp ends, bright polish |

| Safety Features | relief valve; explosion-proof on request |

✅ Why Pick This Mixer?

- Scalable – stay flexible-plug in new recipes without more hardware.

- Cost-Efficient – cut manual work, trim batch times, and boost savings with energy-smart motors.

- Reliable – heavy-duty build gives you years of solid, worry-free service.

- Turnkey solution – we handle piping, controls, and full docs so you plug it in and go.

Customization & Ordering

Pick your voltage and wattage so the unit fits your power setup and production volume.

Material options are 316L for heavy-duty chemical work, or 304 for a budget-friendly build.

Let us know how much liquid you need, what kind of agitator you want, and how to control the temperature.

You can add sampling ports, level sensors, CIP spray balls, blast-proof housing, or any feature you need.

Contact our engineers to lock in the final design. We’ll send you clear CAD drawings and a layout for your OK.

Common Questions

Can I adjust the agitator speed?

Yes-almost every unit comes with a variable-speed drive (VFD) so you mix exactly how fast you need.

Is insulation available for high-temperature mixing?

Absolutely-insulated jackets keep heating in and cut energy loss during hot processes.

What delivery options are available?

We ship worldwide and can supervise setup and give tech support long after the sale.

Are ATEX-UL ratings available?

Yes-blast-proof versions plus UL, CE, and ATEX certs come ready if you ask.

Can the tank be skid-mounted or mobile?

For sure-custom skids, wheels, or a blend with your current line can be built.

🛒 Ready to Order or Let Us Build Yours?

Lift your drink-making game with a finely-tuned mixing tank. Whether you’re starting a fresh flavor or ramping up production, we share dependable, custom gear made just for you.