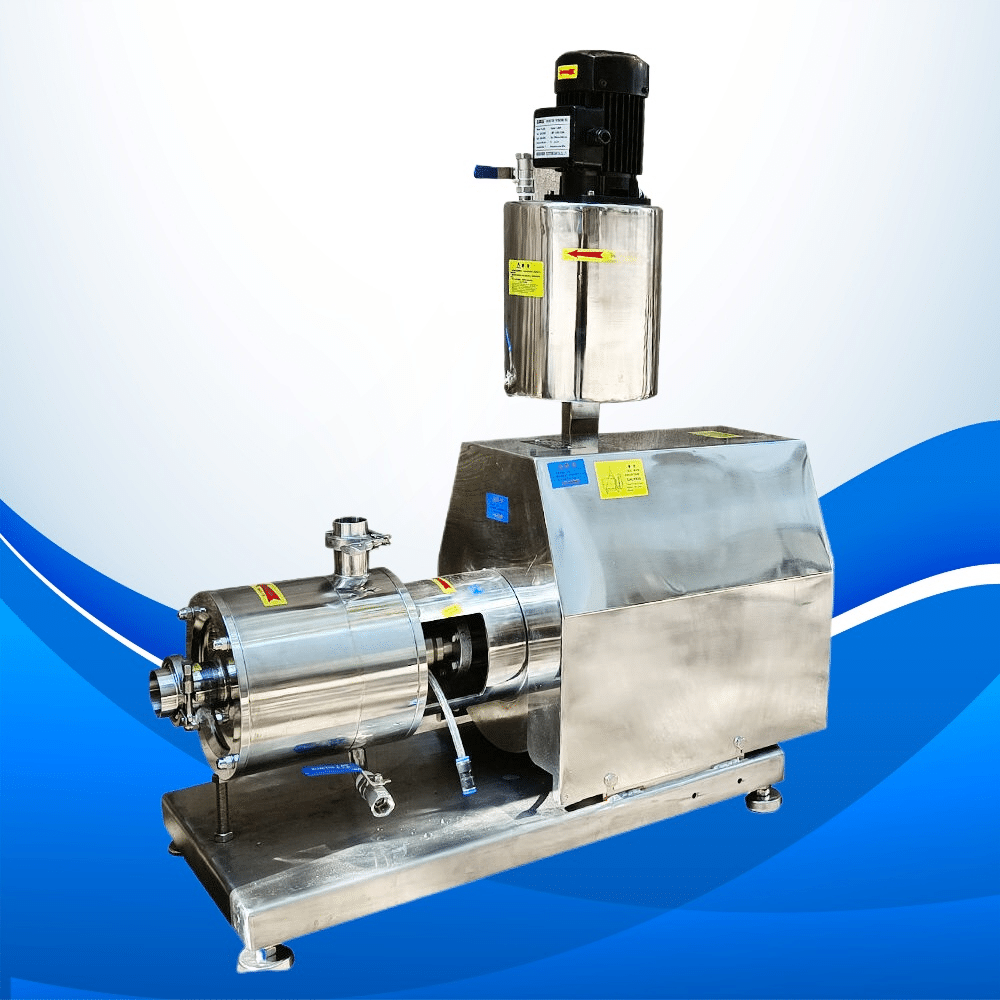

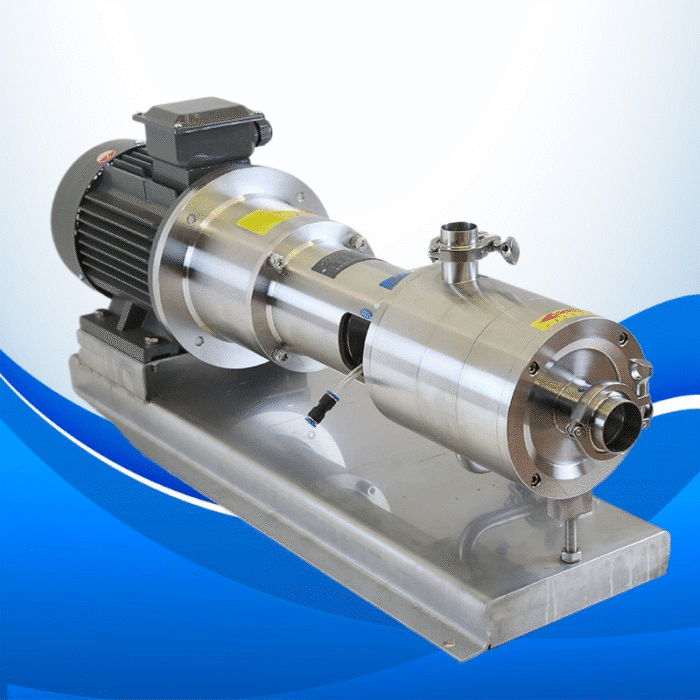

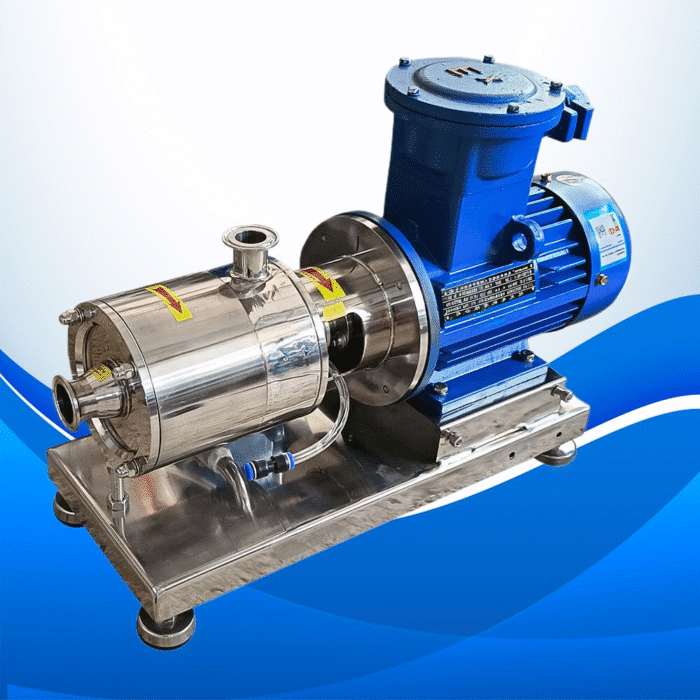

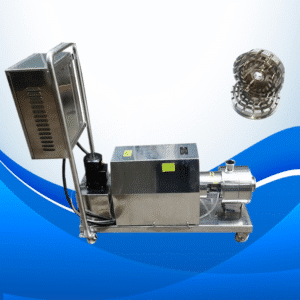

Inline Homogenizer Mixer for Industrial Processing

- Material: 304 or 316L

- Voltage: 110V 208V 220V 380V 400V 415V 480V 600V

- Certificates: CE, GMP, UL, ATEX, ISO 9001

- Power:0.75KW-55KW (1 HP – 74 HP)

- Motor brands: ABB, Chinese brands, SEW, Siemens (optional)

- 1-year free warranty with door-to-door delivery.

- We have it in stock.

- MADE IN CHINA

Please contact our sales team before placing your order.

Email:info@ace-chn.com

Tel:+86 18626835909

WeChat: ace-chn

$2,300.00

Guaranteed Safe Checkout

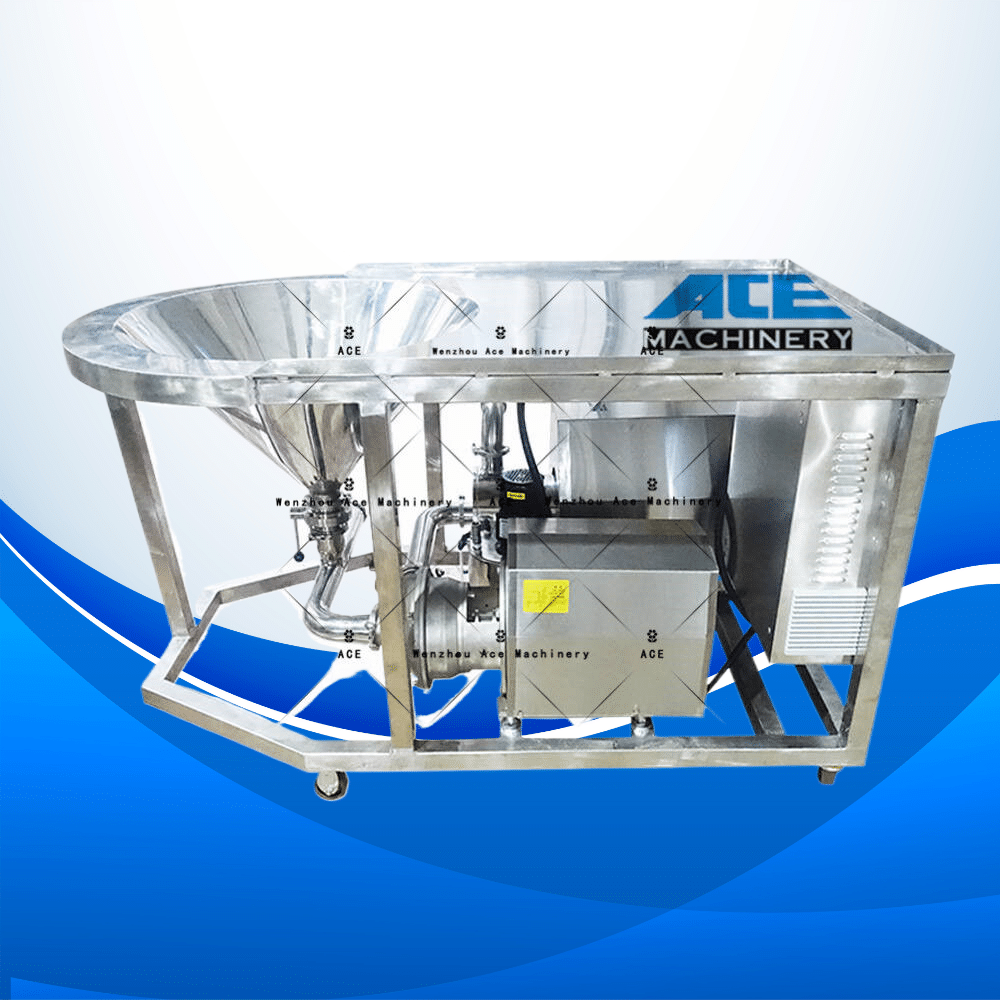

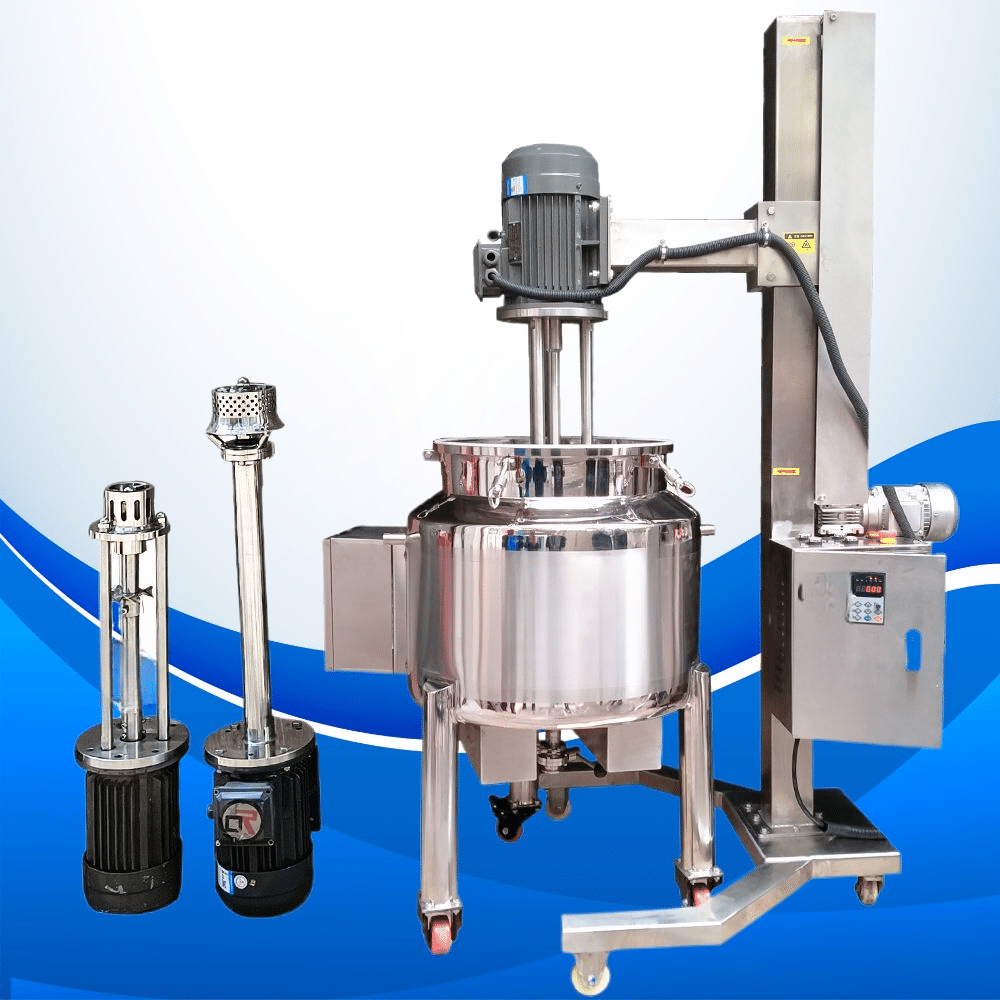

We manufacture and sell the following types of mixers

Mix, emulsify, homogenize, disintegrate and dissolve

Ideal for disintegrating solids and incorporating powders

Reduce mixing times by up to 80%

Reduce mixing times by up to 90%

Quickly disperse and hydrate powders, even at higher viscosities

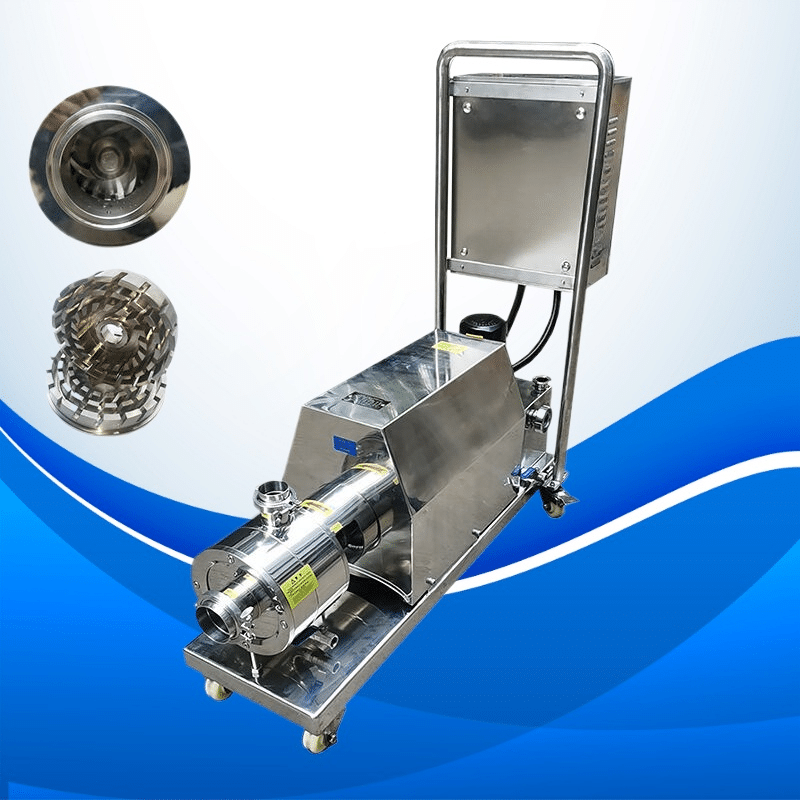

Easy to move and lift

Features heating, cooling, vacuum, and other functions

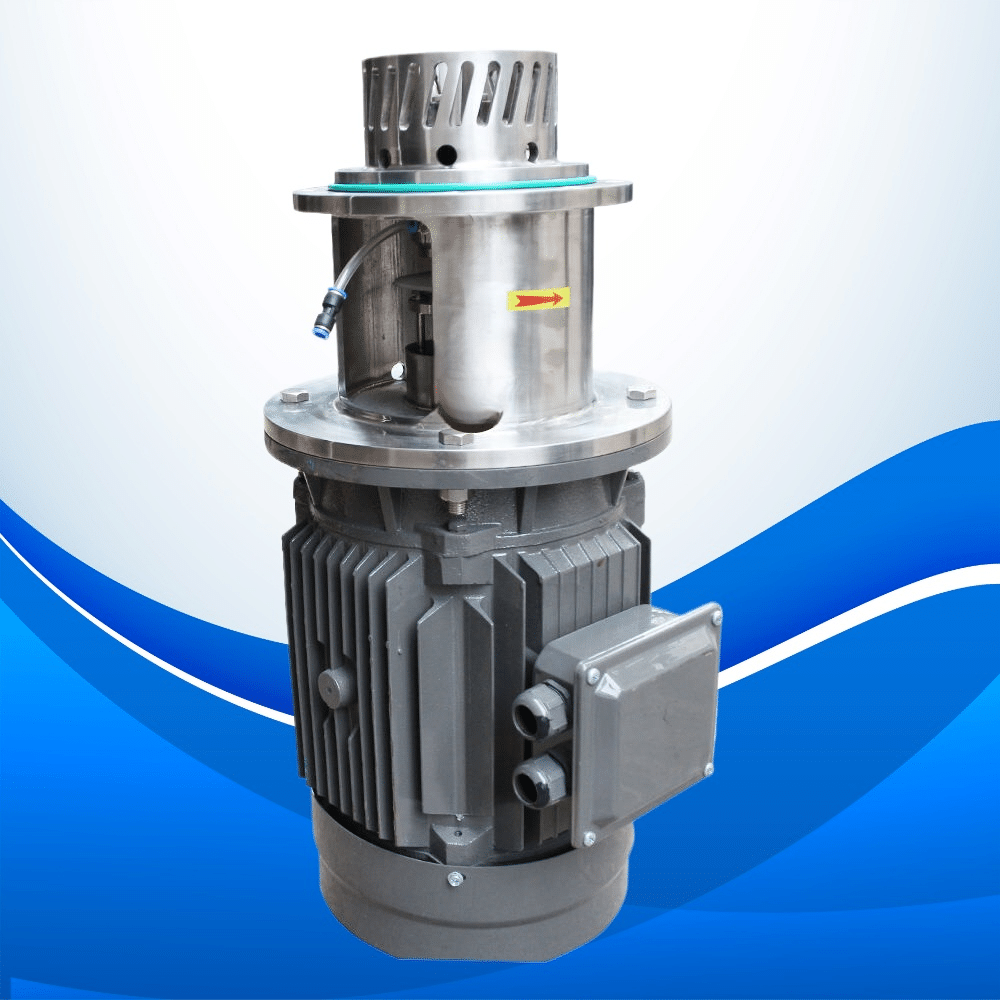

Recommended RPM: 1480/2850 RPM

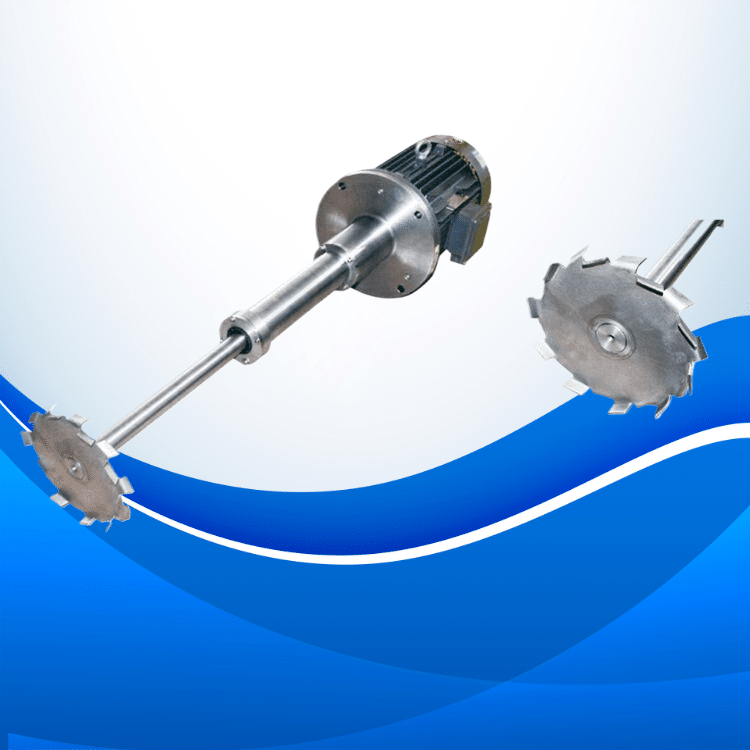

Get Consistent, High-Quality Results with the Inline Homogenizer Mixer

Every manufacturer knows that a smooth product simply sells better. From ice cream to sunscreen, a uniform texture can make or break customer loyalty. The inline homogenizer mixer makes that task easy. Built for round-the-clock operations, it blends, shears, and emulsifies non-stop with very little downtime.

Key Benefits and Features

Steady, High-Shear Mixing

Because it re-circulates through a sealed line, you never lose batch-time, and every drop shares the same quality.

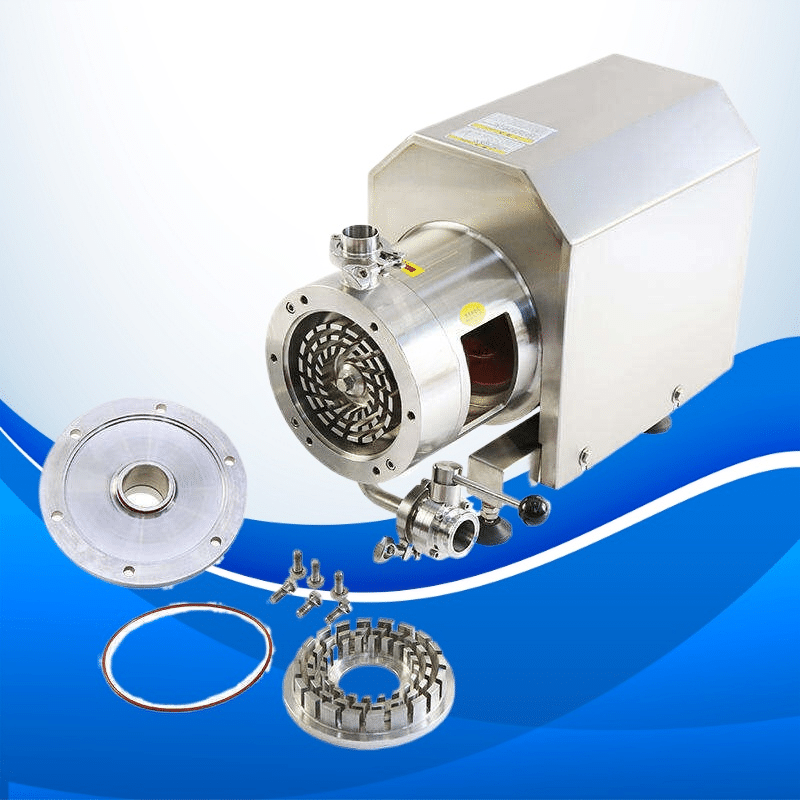

Fine Emulsions, Every Time

Solids and stubborn liquids get chopped into tiny droplets, meaning sauces or creams won’t separate on the shelf.

Power to Match Your Plant

Whether your outlet runs on 110V or 600V, and whether you need 1.5KW or 35KW, we have a model that plugs right in.

Clean-Chem Ready

Made of 304 or optional 316L stainless steel, the unit passes every hygiene test and is designed for quick CIP or SIP wash downs.

Slim Profile, Easy Setup

Its low-line design slips straight into your pipeline, so you spend less time and money installing it.

Applications Across Industries

Food & Beverage

Smooths dressings, dairy drinks, and veggie blends, giving them a shelf-stable look and feel.

Pharmaceutical

Breaks powders down to micron size in creams or suspensions, improving absorption and overall user experience.

Cosmetics and Personal Care Fillers

Use our machine to mix lotions, serums, or shampoo until they feel silky and stay that way on the shelf.

Chemical Processing

It also handles glues, pigments, and other sticky liquids with steady, repeatable results every time.

Technical Specs

| Parameter | Options |

|---|---|

| Power Output | 1.5 kW to 35 kW |

| Voltage | 110 V, 220 V, 380 V, 480 V, 600 V |

| Material | SS 304 or SS 316L |

| Flow Rate | Made to order |

| Rotor-Stator Design | Multi-stage (single or double) |

| Seal Type | Mechanical, Double |

Real-World Examples

Picture a mid-sized food factory that wants to speed up ketchup making without losing flavor or texture. By adding our inline homogenizer, they smooth out lumps, cut quality checks, and boost output by forty percent. Or think about a small skincare lab testing a new hand cream. The teams run a dozen tiny batches, watch the particle size drop, and walk away with a rich yet light formula that’ll hold up on store shelves.

Why Pick Our Inline Homogenizer Mixer?

- Custom set-ups that slide right into your line.

- Killer shear forces for really fine particle size.

- Easy to service, and the parts last forever.

- Proven in factories from food to pharma.

Ready to Upgrade Your Production Line?

If you need higher volume or just a better mixer, ours delivers precision every shift. Reach out for a quote built around your power, material, and industry needs.

Frequently Asked Questions

Q: Can I drop the mixer into my current pipeline?

A: Absolutely. The inline style connects with almost any closed-loop system.

Q: What’s the difference between 304 and 316L stainless steel?

A: 316L resists rust better, so it’s perfect for acidic or salty recipes.

Q: Do you offer custom rotor-stator configurations?

A: You bet. We’ll build single or multi-stage heads, whatever you require.

Q: How do I pick the right voltage and power?

A: Our techs review flow rate and viscosity, then recommend the best combo.