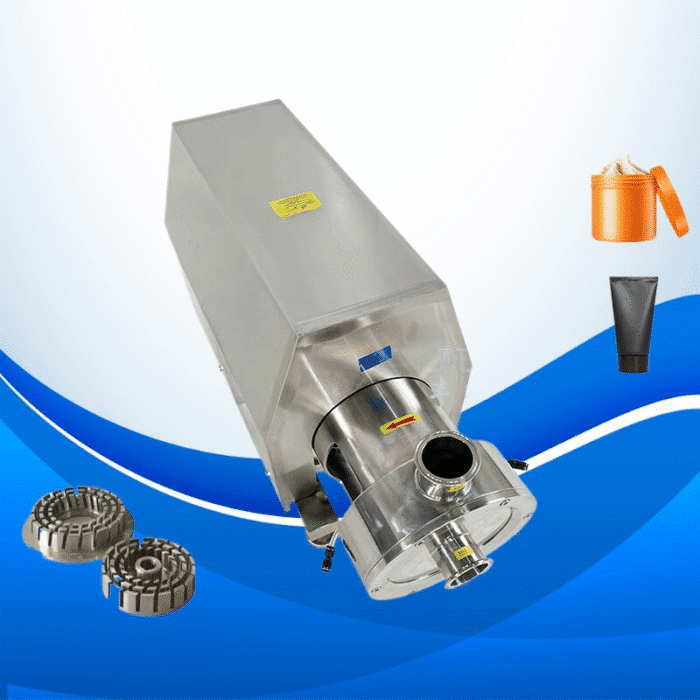

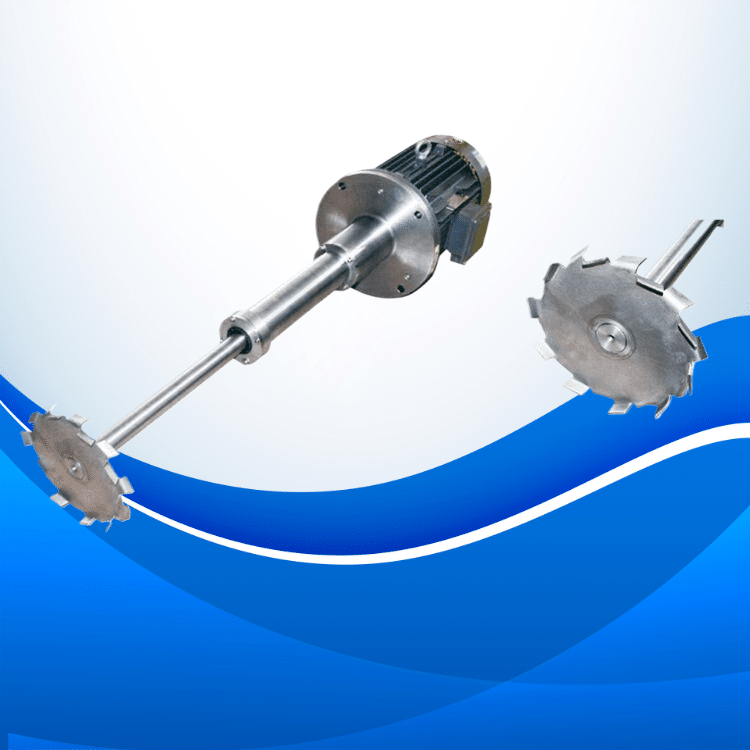

Inline Homogenizer Mixer for Efficient Mixing and Homogenization

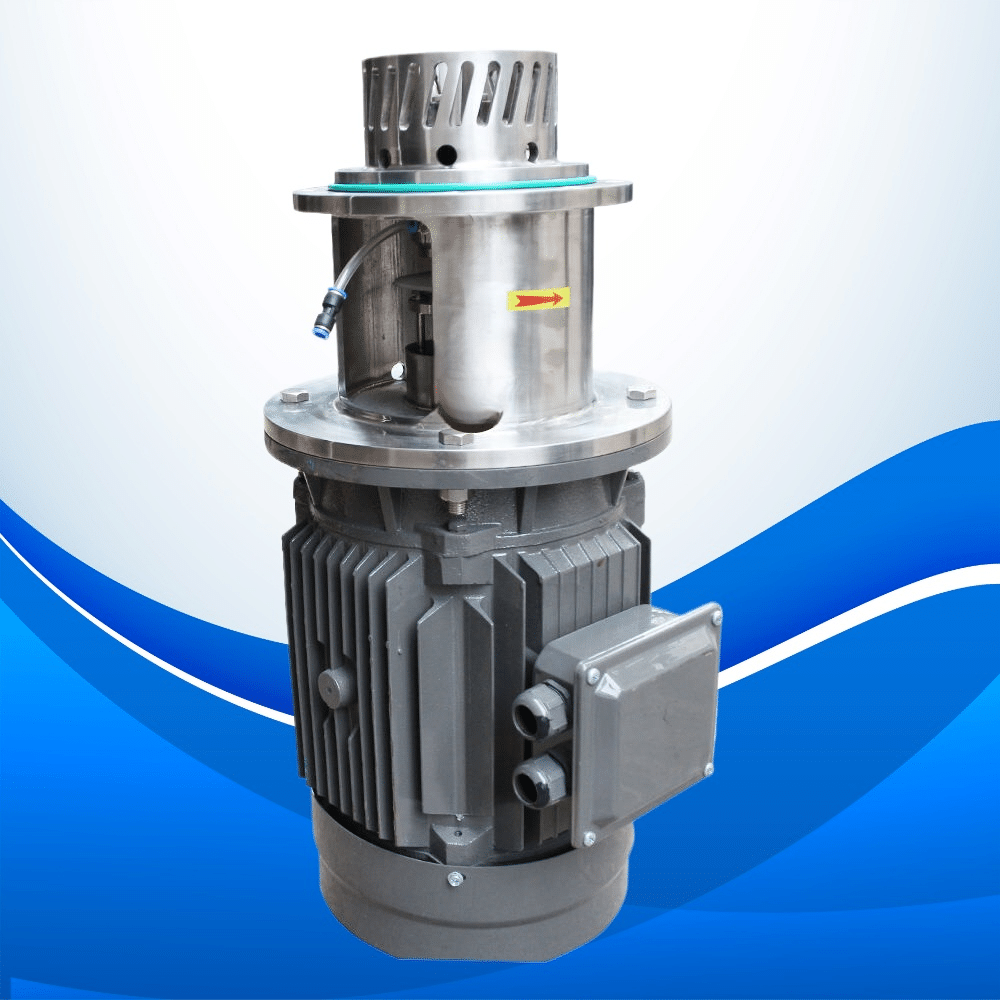

- Material: 304 or 316L

- Voltage: 110V 208V 220V 380V 400V 415V 480V 600V

- Certificates: CE, GMP, UL, ATEX, ISO 9001

- Power:0.75KW-55KW (1 HP – 74 HP)

- Motor brands: ABB, Chinese brands, SEW, Siemens (optional)

- 1-year free warranty with door-to-door delivery.

- We have it in stock.

- MADE IN CHINA

Please contact our sales team before placing your order.

Email:info@ace-chn.com

Tel:+86 18626835909

WeChat: ace-chn

$2,100.00

Guaranteed Safe Checkout

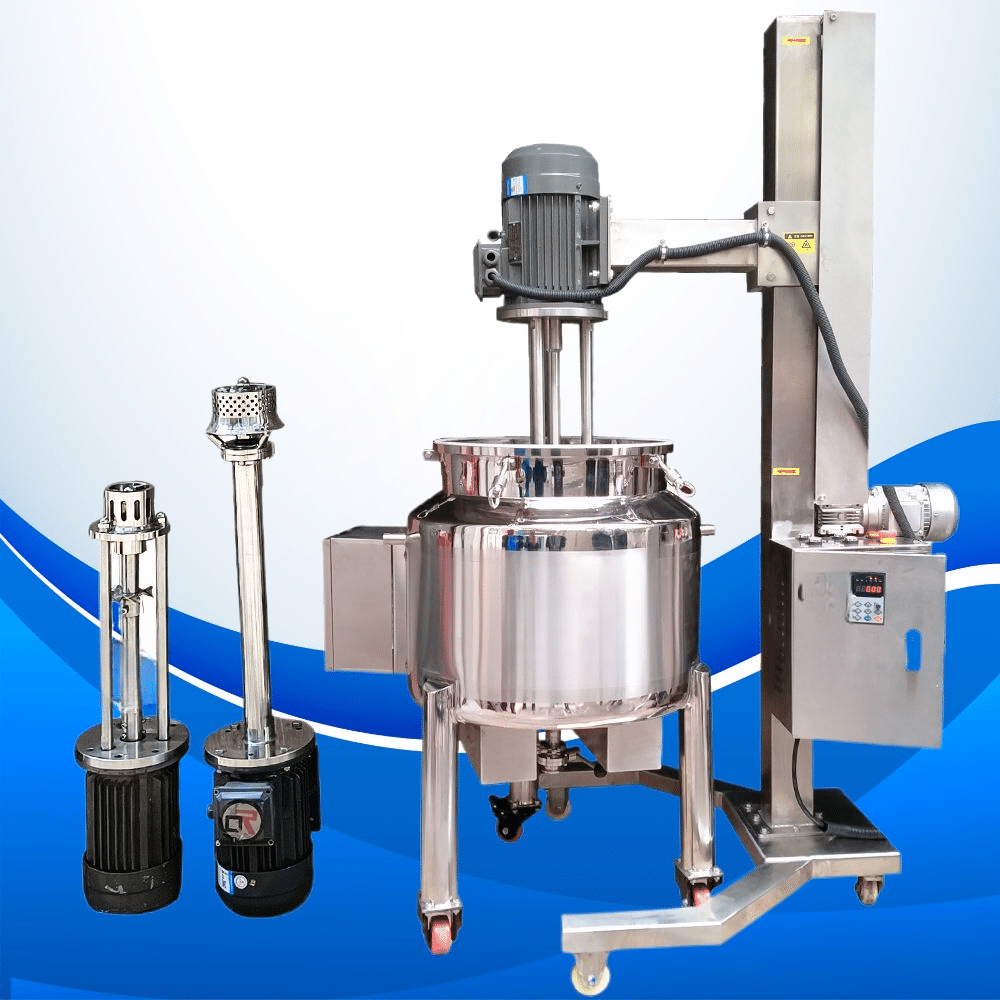

We manufacture and sell the following types of mixers

Mix, emulsify, homogenize, disintegrate and dissolve

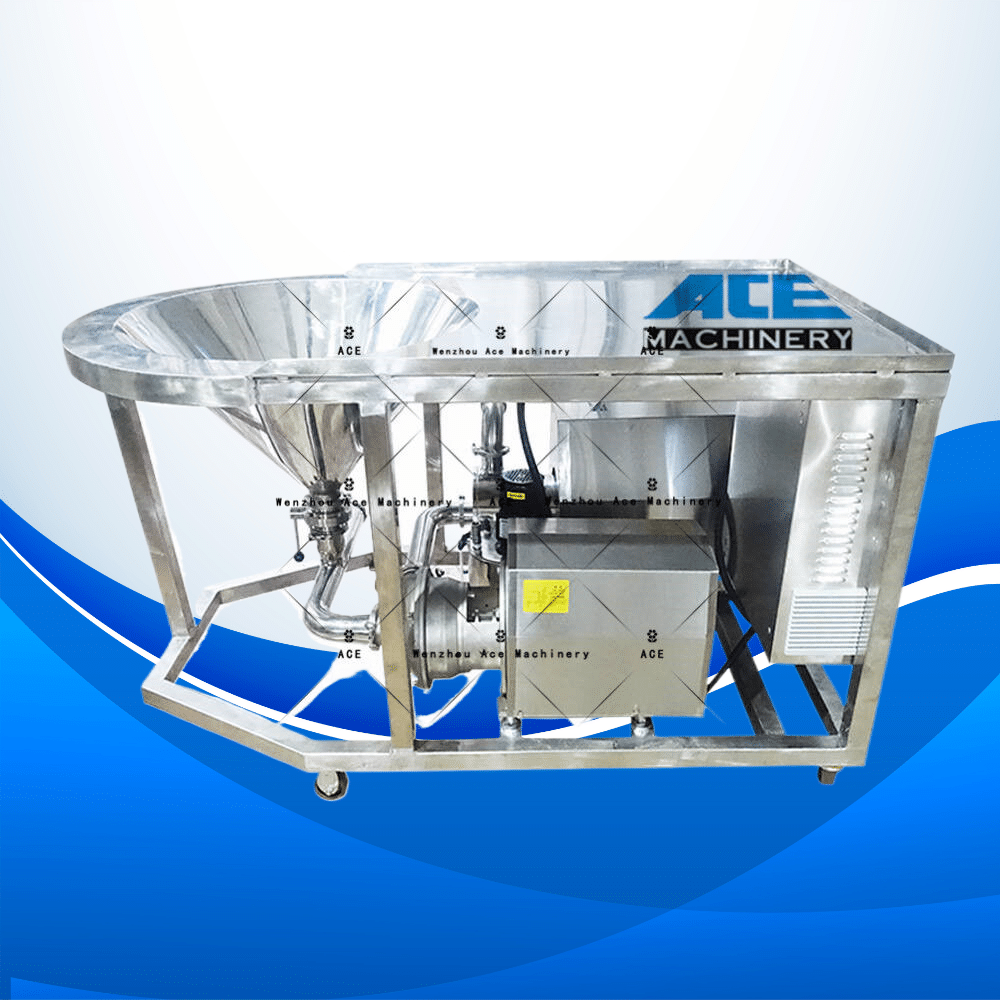

Ideal for disintegrating solids and incorporating powders

Reduce mixing times by up to 80%

Reduce mixing times by up to 90%

Quickly disperse and hydrate powders, even at higher viscosities

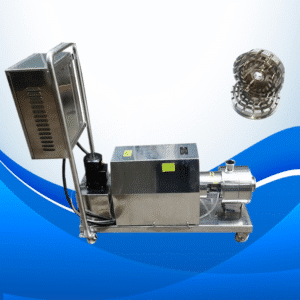

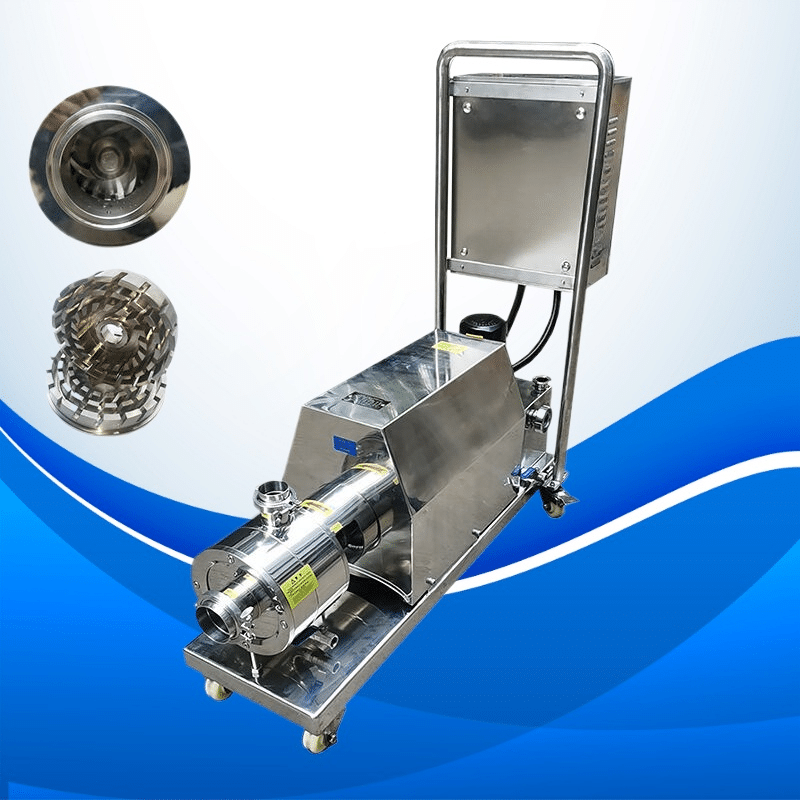

Easy to move and lift

Features heating, cooling, vacuum, and other functions

Recommended RPM: 1480/2850 RPM

Inline Homogenizer Mixer: The Go-To Tool for Fast, Steady Mixing

An Inline Homogenizer Mixer is a smart, purpose-built machine that blends and breaks down ingredients more evenly than most mixers. It fits right into factories making medicine, drinks, lotions, or chemicals, giving everyone a dependable way to keep every batch tasting and looking the same. Because you can choose the motor power, voltage, and material finish, the mixer can match whatever set up your line already has.

Better Mixing Every Time

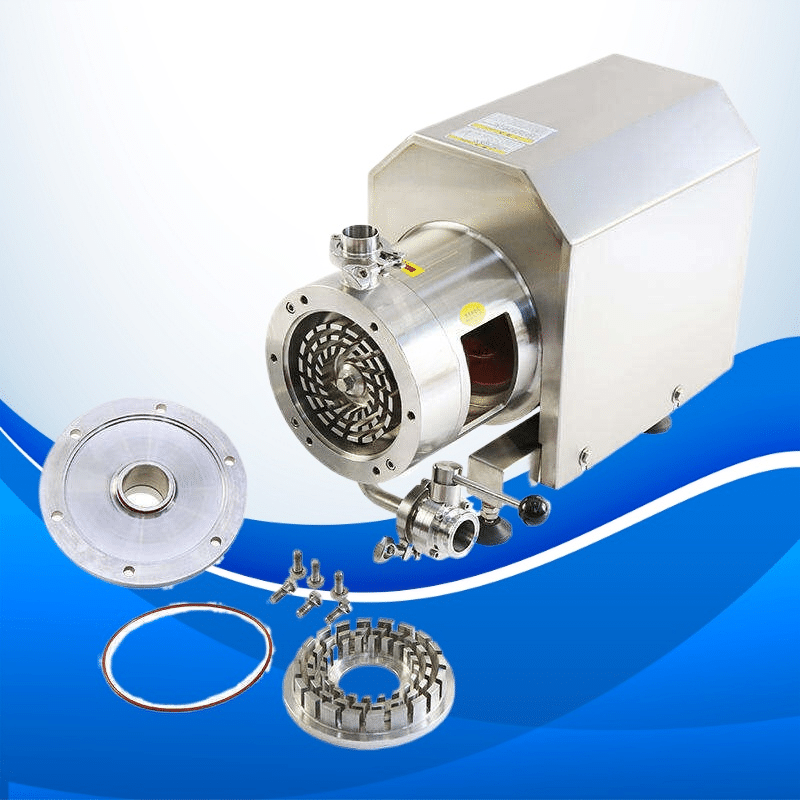

Thanks to its clever rotor-and-stator design, the Inline Homogenizer Mixer cuts particles, whips air out, and folds liquids together all at once. By doing that in real time, the mixer stops lumps from forming later, cuts the amount of grinding you have to do, and protects the flavor and color in every bottle or jar. Customers notice the smoother mouth-feel, longer shelf life, and brighter appearance that come from truly even mixing.

Faster, Cheaper Operation

Because it’s ready for nonstop duty, the inline mixer keeps your line moving without pauses to reload. You slide the tube right into the conveyor, and it suddenly becomes one long mixing drum, which cuts hours of cleaning and assembly. The tight design also uses way less power than the big tanks and pumps needed for batch mixing, so utilities drop and profit margins stretch.

Customizable Features

The Inline Homogenizer Mixer lets you tweak a bunch of things so it works for you.

Voltage

Pick any input from 110V all the way up to 600V, so it plugs right into the power you already have.

Power

Select a motor that runs from 1.5KW for small batches to 35KW if you need heavy-duty output during long shifts.

Materials

You can order the housing in food-grade 316L or 304 stainless steel, giving you the strength, corrosion resistance, and clear safety logs many factories now demand.

Compact and Space-Saving Design

Because the unit mounts inline, it slips into tight layouts and keeps a low profile. That frees up floor space for other gear and helps plant managers trim waste without losing mixing muscle.

Applications of Inline Homogenizer Mixer

This mixer crosses industry lines and handles many mixing chores. Look at a few typical jobs.

Food and Beverage Industry

In food plants, it blends oils with water to make silky emulsions like mayonnaise, dressings, and sauces. It also pipes through dairy, juices, and ready-to-drink beverages so every bottle tastes and looks the same.

Pharma and Cosmetics

The Inline Homogenizer Mixer is a must-have in drug and beauty-product factories. It turns chunky mixtures into silky creams, lotions, and ointments, and works just as well when you need careful mixing for emulsions, extractions, or dispersions.

Chemical Manufacturing

In chemical plants, it makes sure that dyes, coatings, and adhesives blend evenly every time. Because it can tame super-thick liquids and slurries, people also rely on it when they are making paints, protective finishes, and specialty chemicals.

Biotech and Lab Work

Researchers love it, too. Because it handles tiny batches without losing accuracy, it helps in growing cell cultures, preparing suspensions, and whipping up emulsions in every kind of lab from university to start-up.

Product Specifications

Voltage Range: 110V to 600V

Power Range: 1.5KW to 35KW

Material Options: 316L or 304 Stainless Steel

Max Flow Rate: Up to 10,000 liters per hour, depending on model

Homogenization Pressure: 20-200 bar

Custom Options Available: Tell us what you need, and we will build a system just for you.

Why Choose Our Inline Homogenizer Mixer?

High Performance: Built for heavy use, it delivers steady, top-quality results batch after batch.

Energy Saving-Designed to use less power while boosting production speed.

Customizable-Pick the wattage, voltage, and materials that fit your shop.

Durable-Made with rust-resistant 316L and 304 stainless steel, so it stands up to daily use.

Call to Action-Grab Your Inline Homogenizer Mixer Today

For a mixer that is efficient, tough, and easy to tweak, you are in the right place. Our Inline Homogenizer slips into any line, keeps working hard, and can be adjusted as your needs shift. Reach out and tell us what you want; we will build a setup just for you. Ask for a quote or give our sales crew a quick call to get started!

Frequently Asked Questions (FAQs)

What is the difference between the 316L and 304 stainless steel options?

316L fights rust even better, so it shines in food, pharma, or chemical work.304 is cheaper and great for most everyday factory jobs.

Can the Inline Homogenizer Mixer be used for both small and large-scale production?

Absolutely; with different sizes and power levels, it handles tiny test runs or a full-speed factory line.

How can I figure out which voltage and power options I need?

The right voltage and power settings really depend on what you’re making and how big your operation is. Just reach out, and well help you pick the setup that fits your plant best.

Can you build something special just for my project?

You bet! We do one-of-a-kind solutions designed around your exact needs. Send us your details, and well partner with you to create the perfect system.