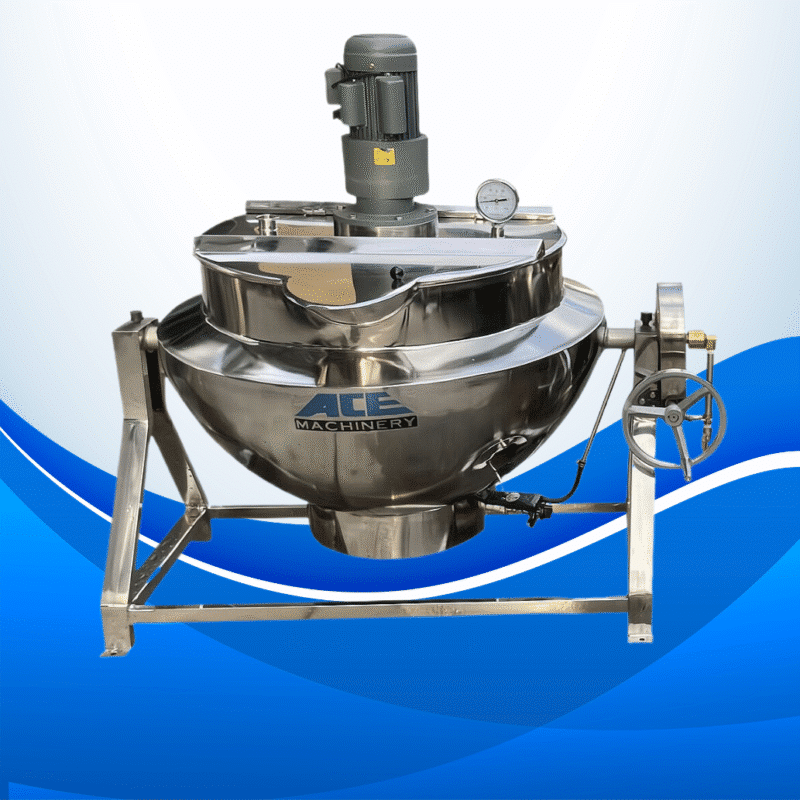

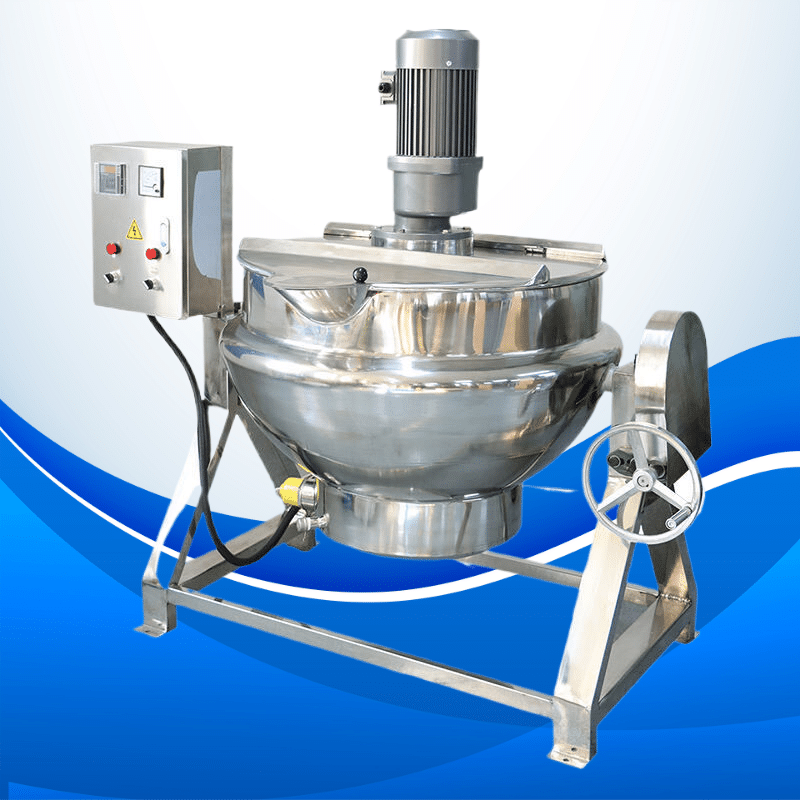

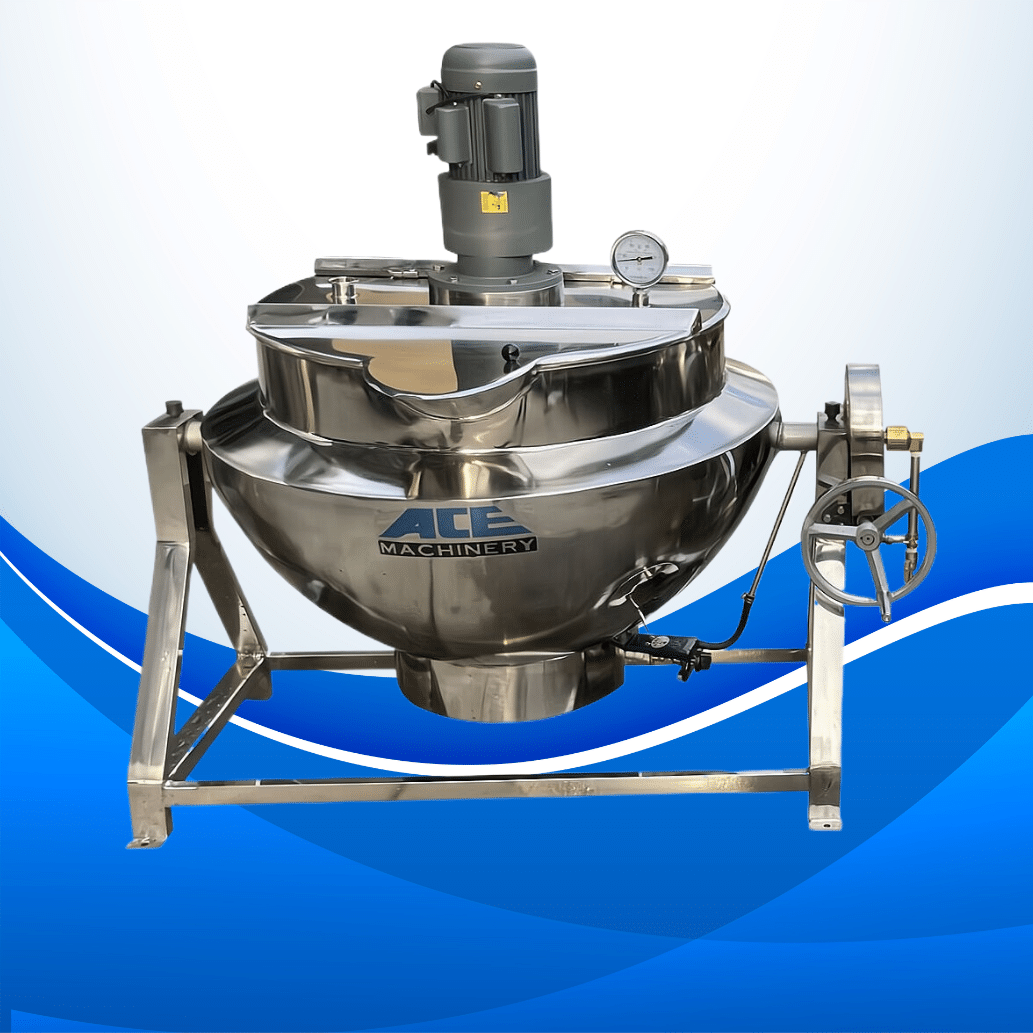

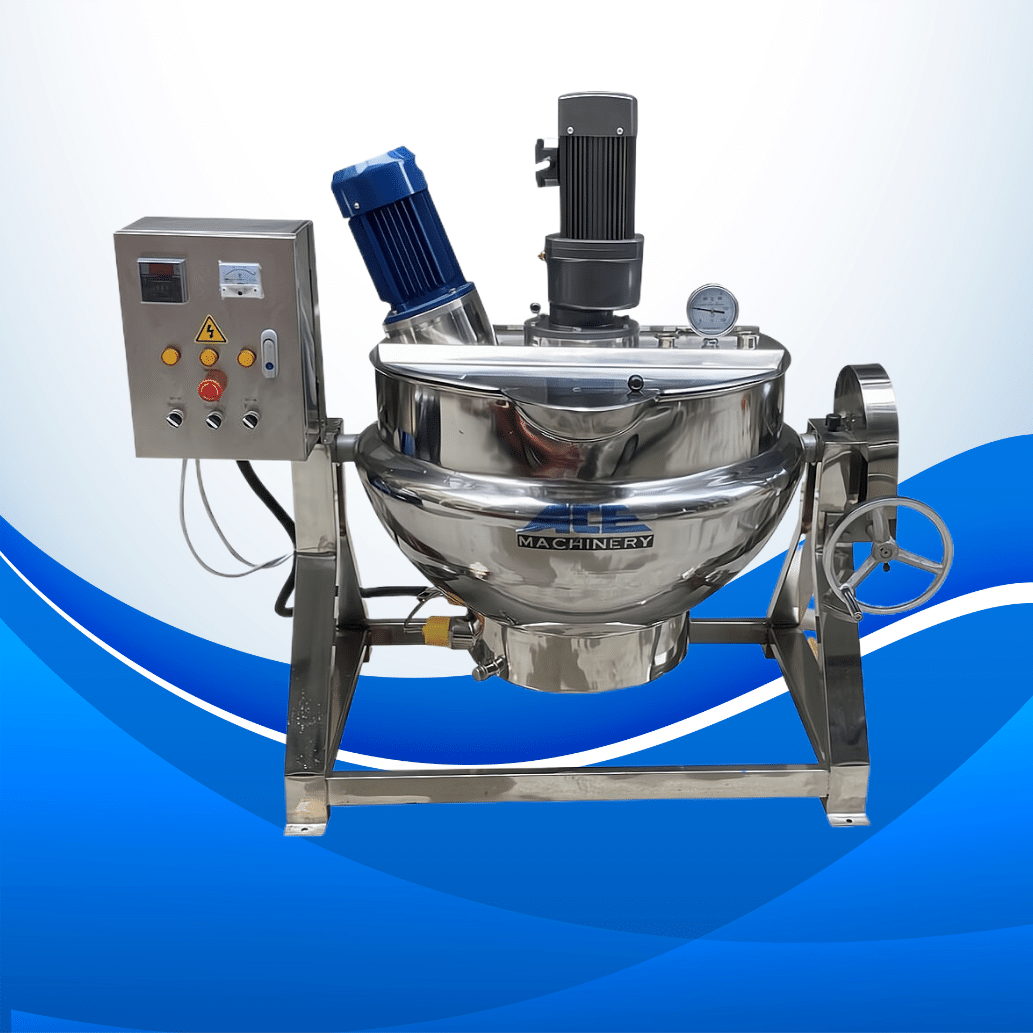

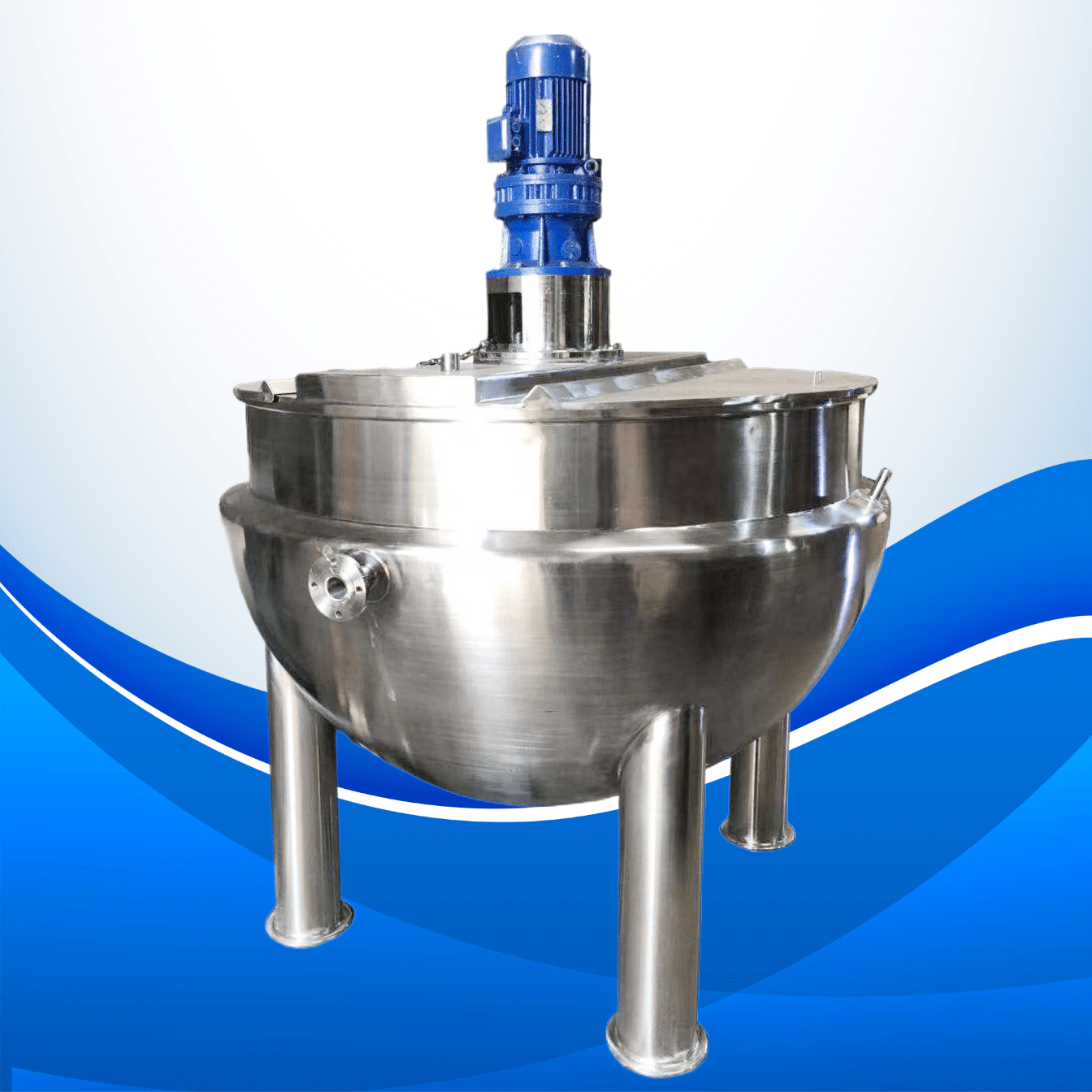

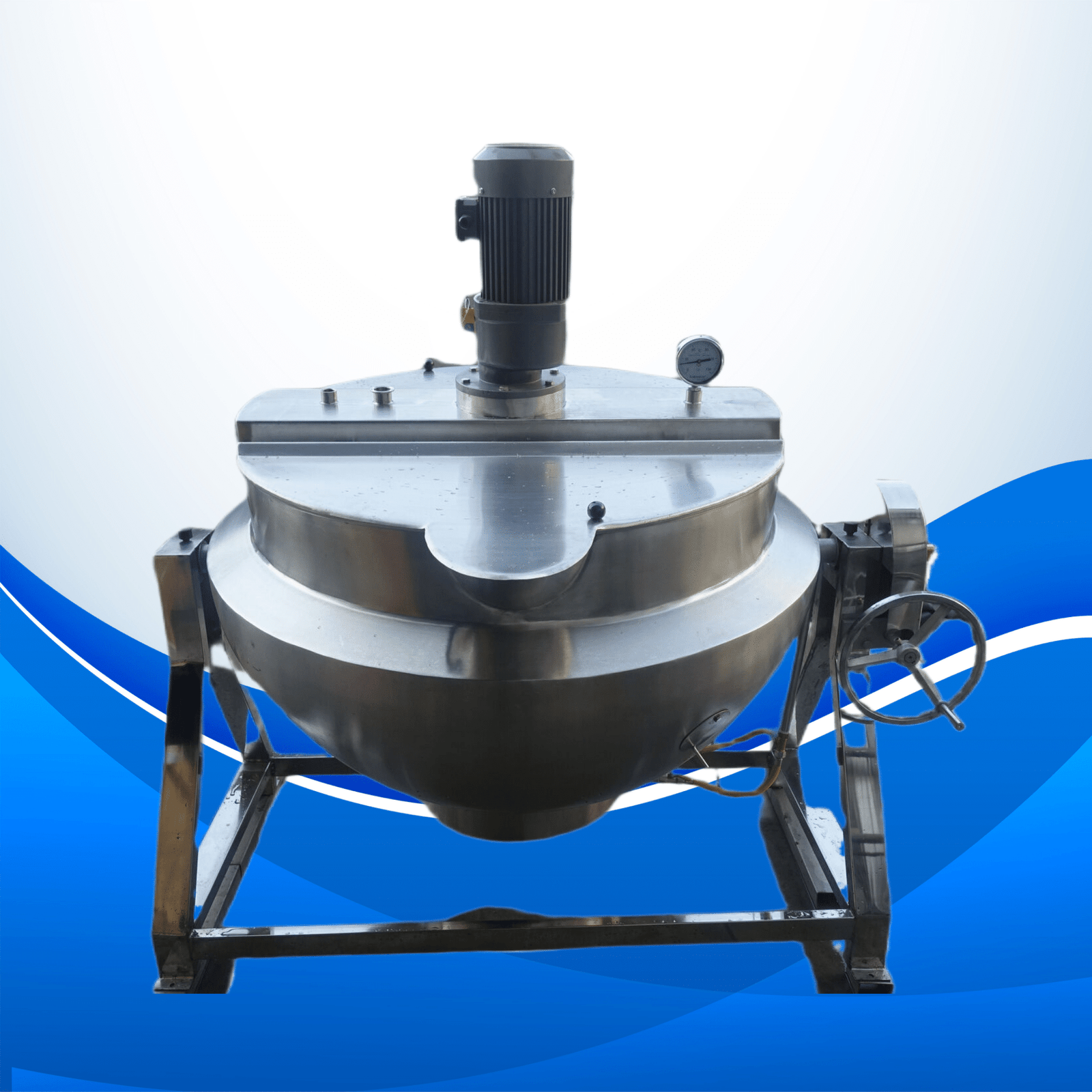

Industrial Jacketed Kettle

- Capacity: 50 liters to 1,000 liters

- Mixer power: 1.5 kW to 11 kW

- Material: 304 or 316L

- Voltage: 110V to 600V

- Heating method: Electric heating, gas heating, natural gas heating, steam heating

- Mixer types: Scraper Mixer, High-Shear Mixer

- Certificates: ASME, CE, GMP, UL, ATEX, ISO 9001

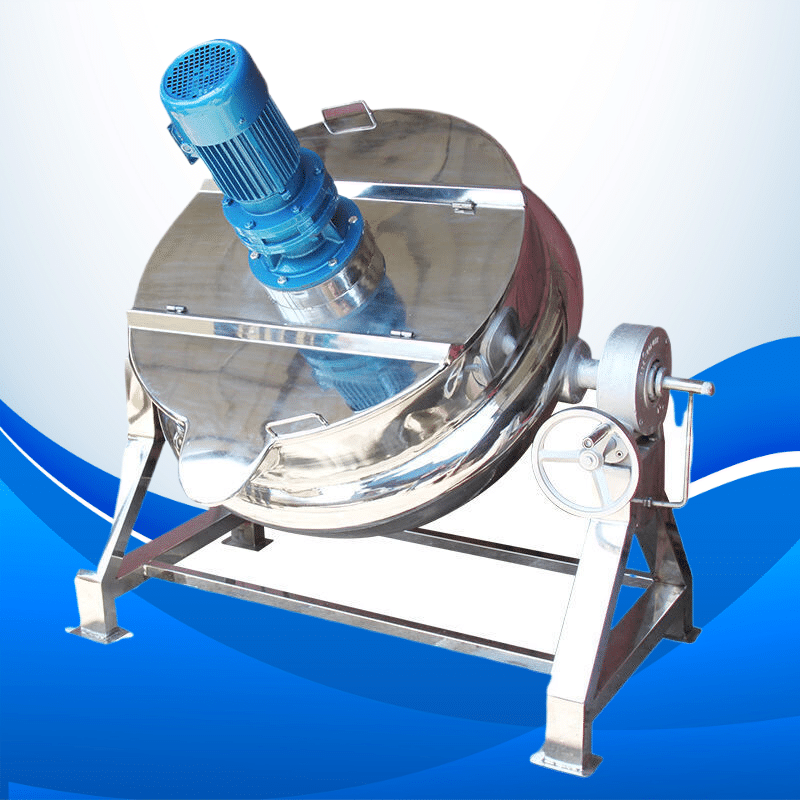

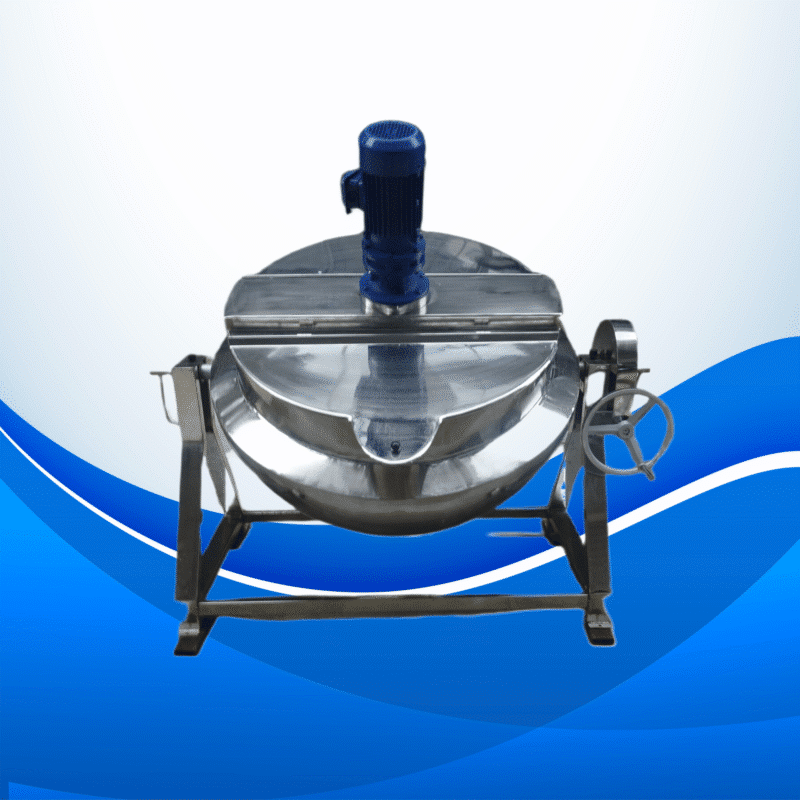

- Optional:Vertical, Tiltable

- MADE IN CHINA

Note: Please contact our sales team before placing an order. Website prices are for reference only; specific pricing requires understanding your requirements to provide a quote.

Email:info@ace-chn.com

Tel: +86 186 2683 5909

WeChat: ace-chn

WhatsApp: +86 186 2683 5909

$1,780.00

Guaranteed Safe Checkout

We manufacture and sell jacketed kettles for electric heating, steam heating, gas heating, and fuel heating applications. Capacities range from 50 liters to 1000 liters.

An industrial jacketed kettle is a heavy-duty cooking machine made for kitchens that need to prepare big batches, day in and day out. The kettle has a special outer shell, or jacket, that surrounds the cooking bowl, letting steam or hot water crawl around the outside instead of blasting directly on the food. Because that gentle, all-around heat slows down the chance of burning sauces, custards, or other delicate mixes, users gain more control and peace of mind. Built with extra-strength welds and easy-clean features, these kettles keep working hard in food plants, chemical labs, and catering kitchens around the world.

Key Features and Benefits

When a cooking operation scales up, even small efficiency gains add up fast, and that’s where the jacketed kettle really shines. The double-walled, jacketed design spreads heat evenly from bottom to rim, so every drop of liquid warms at the same rate. Below are the features that keep large-production lines running smoothly:

- Efficient Heating: Select steam, natural gas, propane, or electric elements for the kettle, and its circling jacket pushes energy into the food rather than waste. Operators notice shorter cook cycles and smaller utility bills.

- Durability: Built from 304 or 316L stainless steel, the unit brushes off rust, acids, and heavy drops, extending service life and lowering replacement costs. Those grades handle punishing temps without warping or pitting.

Built to Fit Every Kitchen

Industrial jacketed kettles come in sizes from 50 to 1000 liters, so you can order one that matches your kitchen’s workload. Whether you need a small unit for artisan batches or a giant kettle for full-production runs, these bowls are built to meet your operation’s exact demand.

Perfect Mixing, Every Time

With agitator motors between 1.5 kW and 11 kW, the kettle blends ingredients gently yet powerfully. That steady motion keeps product from sticking, burning, or cooking unevenly, giving you the same end result jug after jug.

Keep Heat Where It Counts

Because the kettle is heated all around, you can dial in the right temperature and stay there. This level of control is especially important when working with fragile items like custards or creams; it protects taste and texture from sudden shocks.

Thanks to these features, many kitchens consider the jacketed kettle an indispensable workhorse. It simply makes high-volume cooking quicker, safer, and smarter.

Heating Options for Every Need

Another big plus is the kettle’s flexible heating system. Depending on what you have available, you can pick the style that keeps your utility bills in check while delivering fast results.

Steam Heating

If your plant already generates steam, this choice wastes almost no energy and cooks even the heaviest batches in minutes. Steam-jacketed kettles shine when turning out sauces, soups, or confections that need steady, moist heat.

Natural Gas Heating

Natural-gas models are perfect for kitchens that need quick startup and predictable fuel costs. The flame burns hot, delivers a strong grate-first, and allows chefs to bring ingredients to a simmer nearly the moment they pour them in.

Electric Heating

For facilities that can’t bring in gas or steam lines, electric heating is both safe and efficient. The system gives operators precise temperature control, and the equipment is simple to install almost anywhere.

Coal Gas Heating

Many large production plants still rely on coal gas heating, a tried-and-true way to cut costs while boosting output. Because the fuel burns steadily, teams enjoy consistent heat across every kettle.

No matter which heating source you pick, there’s a solution that lets your jacketed kettle fit smoothly into your operation.

Customizable Materials and Sizes

The kettle really shines when it comes to customization. You choose the size and material that match your process exactly.

Materials:

- 304 Stainless Steel: Tough and resistant to rust, 304 meets food-grade standards and works well with sauces, soups, and other mildly acidic products.

- 316L Stainless Steel: For jobs with salt, dairy, or highly sensitive ingredients, 316L stands up even better to corrosion, extending the kettle life.

Sizes

The jacketed kettle is offered in a wide range of sizes, from a compact 50 liters all the way up to a hefty 1000 liters. That means, whether you run a cozy café or a busy food plant, you can find the kettle that feels right at home. The smaller units suit artisanal teams who produce small batches, while the big kettles step in when restaurant chains or industrial kitchens need serious volume.

Because of this variety, you can pick a kettle that matches your output and the exact dishes you plan to cook.

Applications and Real-World Use Cases

Jacketed kettles are everywhere in food processing and manufacturing, and they turn up in quite a few other areas, too. Here are some everyday examples that show how valuable they really are:

- Food Processing Industry. From sauces and soups to jams and syrups, large-scale producers rely on these kettles for even heat. The gentle cooking keeps ingredients from burning or splitting, so every batch tastes just right.

- Confectionery Manufacturing. Candies and chocolates need special care during cooking. With precise temperature control, the jacketed kettle helps makers hit the perfect melt and shine every time.

- Beverage Production The kettle is a go-to tool in drink making, whether you’re brewing tea for a café or pumping out fresh coffee for a bakery. Because the walls are heated evenly, hot patches don’t scorch some leaves or ground beans, giving every batch the same rich flavor.

- Pharmaceutical Industry Drug and supplement makers rely on kettles to warm and stir active ingredients. With a dial that won’t budge more than a degree, workers are sure the mix is safe, stable, and up to regulatory standards before leaving the lab.

In both cases, a jacketed kettle keeps the work calm, quick, and repeatable, lifting quality and speeding up the assembly line.

Choosing the Right Industrial Jacketed Kettle for Your Needs

When picking a kettle for your shop, think through these points, so your new gear fits like a glove:

- Heating Method – Match the burner to what’s already in your plant. Steam pipes, gas jets, and electric coils all work, but some will cost less to run and clean than others.

- Size and Capacity – Map out how many liters you boil each hour and grab a pot that can keep pace. High-volume bakeries love wide, deep kettles, while small farms or craft kitchens can stick with a nimble 50-liter model.

- Material Stainless steel is what most food makers pick for jacketed kettles because it lasts a long time and hardly ever rusts. Depending on how you plan to use the kettle, you can go with standard 304 or upgrade to the tougher 316L grade.

When you know your cooking, cooling, and cleaning routines, it’s much easier to choose the kettle size and extras that will keep your line moving fast while making every batch taste the same.

Call to Action & FAQs

Is it time to speed up your plant? An industrial jacketed kettle will give you better control over heat, cut steam use, and reduce cooking times. Pick the model that fits your setup and feel the improvement right away.

Common Questions:

- What is the difference between 304 and 316L stainless steel? 316L resists corrosion from salt and some cleaning chemicals even better than 304. If you handle high-acid foods, that extra protection can extend the kettles life

- Can I choose a custom-sized kettle? You bet! Kettles come in lots of standard sizes, and many makers will build one to your exact dimensions if the job calls for it.

- How do I maintain the kettle? Keep it clean, look for loose bolts, and listen for any strange noises from the heating coils or agitator. A quick weekly check almost always beats a pricey repair later.

Ready to get started? Call or e-mail us, and well help you configure the perfect kettle for your plant.