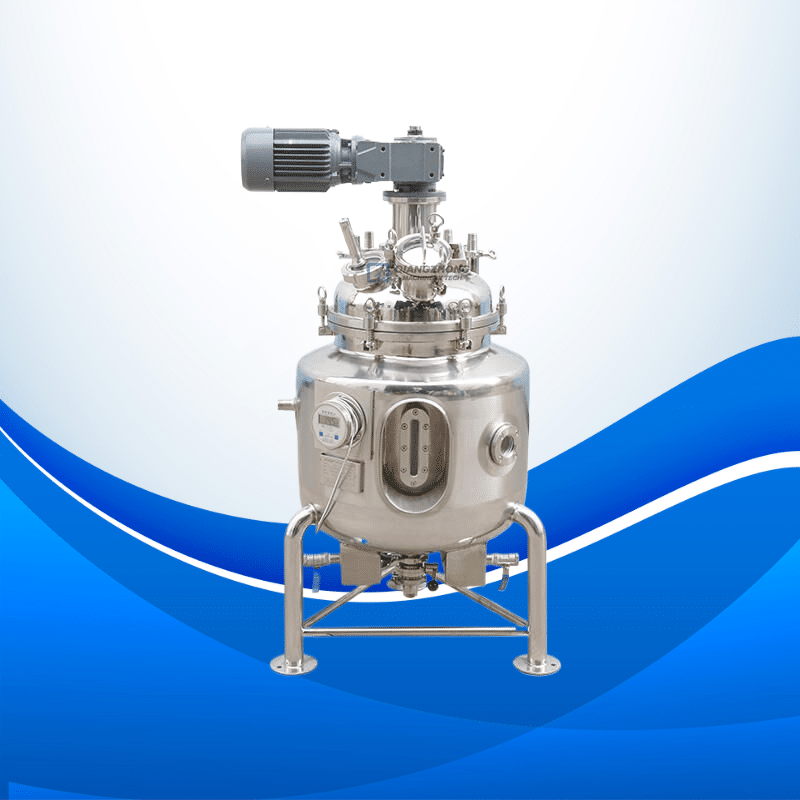

Industrial Hot and Cold Mixing Tank

- Capacity: 50 liters to 30,000 liters

- Mixer power: 1.5 kW to 55 kW

- Material: 304 or 316L

- Voltage: 110V to 600V

- Heating method: Electric or steam heating

- Layer:single/double jacket/three jacket

- Mixer types: Impeller-type, Anchor-type, Turbine-type, High-shear-type, Magnetic mixer, Anchor-type mixer with scrapers,dispersing

- Optional: platform, wheels, ladder,variable frequency drive,explosion-proof device

- Certificates: ASME, CE, GMP, UL, ATEX, ISO 9001

- Our equipment supports customisation, global delivery, and a 1-year warranty.

- If you have drawings, we can process them for you.

Note: Please contact our sales team before placing an order. Website prices are for reference only; specific pricing requires understanding your requirements to provide a quote.

Email:info@ace-chn.com

Tel: +86 186 2683 5909

WeChat: ace-chn

WhatsApp: +86 186 2683 5909

$4,100.00

Guaranteed Safe Checkout

Recommend RPM: 0-960RPM

Viscosity: Low/medium viscosity

Application: Mainly Liquid mixing

Recommend RPM: 0-200RPM

Viscosity: Low/medium viscosity

Application: Mainly Liquid mixing

Recommend RPM: 30RPM

Viscosity: Medium/High viscosity

Application: Melting, High viscosity product mixing, For single wall tank

Recommend RPM: 30RPM

Viscosity: Medium/High viscosity

Application: Melting, High viscosity product mixing, For jacket tank

Recommend RPM: 1480/2850 RPM

Viscosity: Low/medium viscosity

Application: Liquid powder mixing and dispersion

Recommend RPM: 1480/2850 RPM

Viscosity: Low/medium/High viscosity

Application: Liquid powder mixing and homogenizing

Recommend RPM: 0-355RPM

Viscosity: Low/medium viscosity

Application: Install at bottom, No mechanical seal working condition

Recommend RPM: As above

Viscosity: Low/medium viscosity

Application: Liquid powder mixing and dispersion For tank volume >300L

Custom Hot-and-Cold Mixing Tank for Error-Free Blending

When every batch must meet the same tight standards, a hot-and-cold mixing tank stops being optional-it’s vital. From face creams to drug syrups, our heavy-duty stainless tanks let you heat, cool, and blend without constant babysitting, so you get the quality you expect, every time.

Where You’ll See Us

Our flexible set-up tackles a wide spread of industries so you can mix whatever you need, done right:

Cosmetics

Vitamins, oils, and water blend smoothly for stable creams and gels.

Food-and-Beverage

Sauces, dairy, flavors, and drinks move quickly through heat-and-cool steps.

Pharmaceuticals

Sterile cycles guard against contamination in ointments and syrups.

Chemical

Tight temperature control guides tricky blends and prevents unsafe spikes.

Eliminating time wasted moving batches between separate heaters and chillers boosts overall speed.

Clarity in Custom Build

Think of our tanks like a blank canvas; you pick the extras that match your shop-floor needs:

- Material: 304 stainless for solid savings or costly 316L when acid, salt or pure air is a risk.

- Voltage compatibility: Choose any supply from 110V up to 600V, single- or three-phase, so the unit fits your existing power.

- Tank capacity: Pick a volume anywhere between 50 liters and a whopping 5000 liters, with larger tanks available on request.

- Extra options: Like automated temperature control, digital readouts, clean-in-place (CIP) lines and high-shear mixing heads can be added, based on what you make.

Why choose our hot-and-cold mixing tank?

- Fast temperature changes: The jacketed shell lets you heat and chill at once or take turns, slicing batch time.

- Hygienic and easy to clean: Super-smooth welds with optional CIP hardware cut germs and speed up Ashdown.

- Tough and safe: Built to GMP rules from premium stainless steel, the tank delivers reliable, longline service.

- Energy smart: Thick, high-grade insulation keeps heat in so cooling and heating use less power, even on long runs.

- Custom engineering help: Our engineers team up with you to craft a system that suits your exact process needs.

Picture your workflow:

Now imagine making a batch-beginning to end-with just one handy tank. With preset temps and speed-control paddles, your crew can dial in recipe, texture and timing.

From a small lab mixing five liters of gel at the end of a Friday afternoon to a factory running day and night on-boarding tens of thousands of units an hour, this hot-and-cold mixing tank slips into the workflow without a hitch.

Order & Customization

Every production line is unique, so we never push off-the-shelf solutions. Get in touch for a quote built around your power source, voltage range, and precise capacity.

Ready to upgrade your production process?

Lock in your custom hot-and-cold tank today and feel the difference, if precision meets reliability.

Frequently Asked Questions (FAQ)

Q1: What size tank should I choose?

Your average batch volume calls the shots. Our team will walk you through the math and pick the best capacity.

Q2: Can the tank operate in both heating and cooling modes simultaneously?

Yes, our dual-zone models handle heating and cooling at the same time.

Q3: Is 316L stainless steel necessary for food or cosmetic use?

304 stainless works for most food applications, but 316L is a smarter choice when purity or corrosion is a concern.

Q4: Can I integrate this tank into an automated production line?

Absolutely. Every tank plays nice with modern PLC systems and factory-control networks.

Q5: What is the lead time for custom orders?

Depending on the specs and order size, you can expect delivery in roughly two to six weeks.