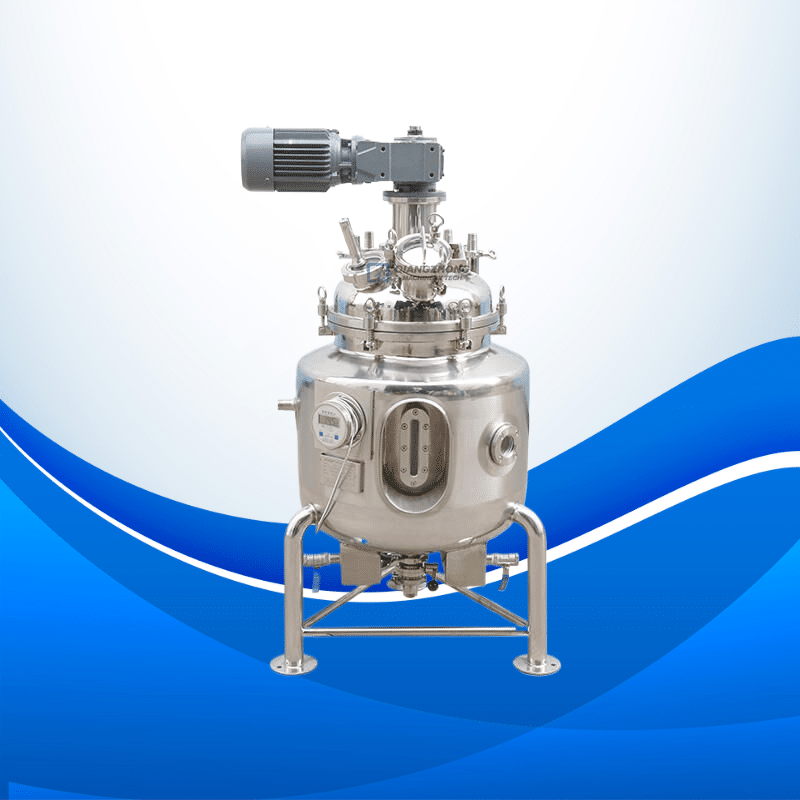

Industrial Emulsification Mixing Tank

- Capacity: 50 liters to 30,000 liters

- Mixer power: 1.5 kW to 55 kW

- Material: 304 or 316L

- Voltage: 110V to 600V

- Heating method: Electric or steam heating

- Layer:single/double jacket/three jacket

- Mixer types: Impeller-type, Anchor-type, Turbine-type, High-shear-type, Magnetic mixer, Anchor-type mixer with scrapers,dispersing

- Optional: platform, wheels, ladder,variable frequency drive,explosion-proof device

- Certificates: ASME, CE, GMP, UL, ATEX, ISO 9001

- Our equipment supports customisation, global delivery, and a 1-year warranty.

- If you have drawings, we can process them for you.

Note: Please contact our sales team before placing an order. Website prices are for reference only; specific pricing requires understanding your requirements to provide a quote.

Email:info@ace-chn.com

Tel: +86 186 2683 5909

WeChat: ace-chn

WhatsApp: +86 186 2683 5909

$4,800.00

Guaranteed Safe Checkout

Recommend RPM: 0-960RPM

Viscosity: Low/medium viscosity

Application: Mainly Liquid mixing

Recommend RPM: 0-200RPM

Viscosity: Low/medium viscosity

Application: Mainly Liquid mixing

Recommend RPM: 30RPM

Viscosity: Medium/High viscosity

Application: Melting, High viscosity product mixing, For single wall tank

Recommend RPM: 30RPM

Viscosity: Medium/High viscosity

Application: Melting, High viscosity product mixing, For jacket tank

Recommend RPM: 1480/2850 RPM

Viscosity: Low/medium viscosity

Application: Liquid powder mixing and dispersion

Recommend RPM: 1480/2850 RPM

Viscosity: Low/medium/High viscosity

Application: Liquid powder mixing and homogenizing

Recommend RPM: 0-355RPM

Viscosity: Low/medium viscosity

Application: Install at bottom, No mechanical seal working condition

Recommend RPM: As above

Viscosity: Low/medium viscosity

Application: Liquid powder mixing and dispersion For tank volume >300L

Enhance Your Blending Process With The Right Engineering

When a product has to look, feel, and act the same every time—thin lip balm, cough syrup, salad dressing, or even paint—you need more than just any mixer. You need an emulsifying mixing tank. These units are built to blend, break down, and smooth out tricky recipes, delivering the same high standard batch after batch.

🏭 Applications That Drive Results

Whether your team is turning out body lotions, whipping cream fillings, or suspending active ingredients in pills, the tank slips into your line without drama. Its sturdy build tackles everything from thin water gels to thick pastes, wasting little power and leaving more energy for great results.

You’ll find it working in:

- Creams, ointments, and gels in pharmaceutical labs

- Food emulsions like mayonnaise, sauces, and dairy blends

- Industrial chemical suspensions and lubricants

- Cosmetic products like serums, conditioners, and cleansers

🔧 Key Features And Customization Options

Voltage Compatibility:

Models are ready from 110V to 600V, so they plug in almost anywhere.

Power Range:

Choose a tidy 1.5kW unit for test batches, or step up to a beefy 55kW plant model for round-the-clock runs.

Material Choices:

316L stainless steel, food and pharma approved, resists rust and stains.

More budget-friendly 304 stainless still works well for everyday jobs.

Design Highlights:

- Rotor-stator setup spins at high speed for super-smooth blending.

- Optional shell stands up to both vacuum and high pressure.

- Thermos jacket keeps heat-sensitive mixes at a steady temp.

- Built-in CIP/SIP cuts cleaning time and keeps things sanitary.

💡 Why Pick This Tank?

- Speed: Even tough ingredients blend fast, so you spend less time per batch.

- Versatility: Handles small batches or runs nonstop on a larger line.

- Sturdy: Heavy-duty builds and top-grade parts keep it running for years.

- Smart: Safety alarms stop overheating, overload, and pressure problems early.

⚙️ Quick Spec Sheet

| Voltage | 110V to 600V, step-up options |

|---|---|

| Power | From 1.5 kW to 55 kW bulk heads |

| Material | Choose 316L or 304 grade metal |

| Capacity | Custom size, 50-L to 5000-L plus |

| Controls | PLC touch panel or simple manual |

📦 Fully Custom Build

Every floor plan and recipe differ. Our engineering team works with you to set tank size, mixer style, wiring, and level of automation. Whether your product is thin liquid or thick paste, well match the mix speed and output you need.

🔚 Is It Time to Boost Your Production?

Make your product pop with our custom blending tanks built just for emulsifying. Ask for a price quote or chat with our team to sketch out a mixer that fits your recipe. With worldwide power settings, adjustable motor sizes, and food-safe metals, hitting your target output becomes easy.

❓ Common Questions We Hear

Q1: What size emulsification mixing tank do I need?

A: Well help you pick the right volume by looking at how much you make in each batch and how often you run.

Q2: Can I use this tank for both hot and cold processes?

A: Absolutely. Add the optional heating-and-cooling jackets and control any temp you need.

Q3: What’s the difference between 316L and 304 stainless steel?

A: 316L fights rust even better, so it’s great for drugs or salty liquids.304 works well for most food mixes and general tasks.

Q4: Do you provide international shipping and support?

A: You bet. We ship anywhere and give you local tech help that meets your countries rules.

Q5: Is training provided upon installation?

A: Yes, you can pick on-site or online training, so your crew learns to run the tank safely and smoothly.