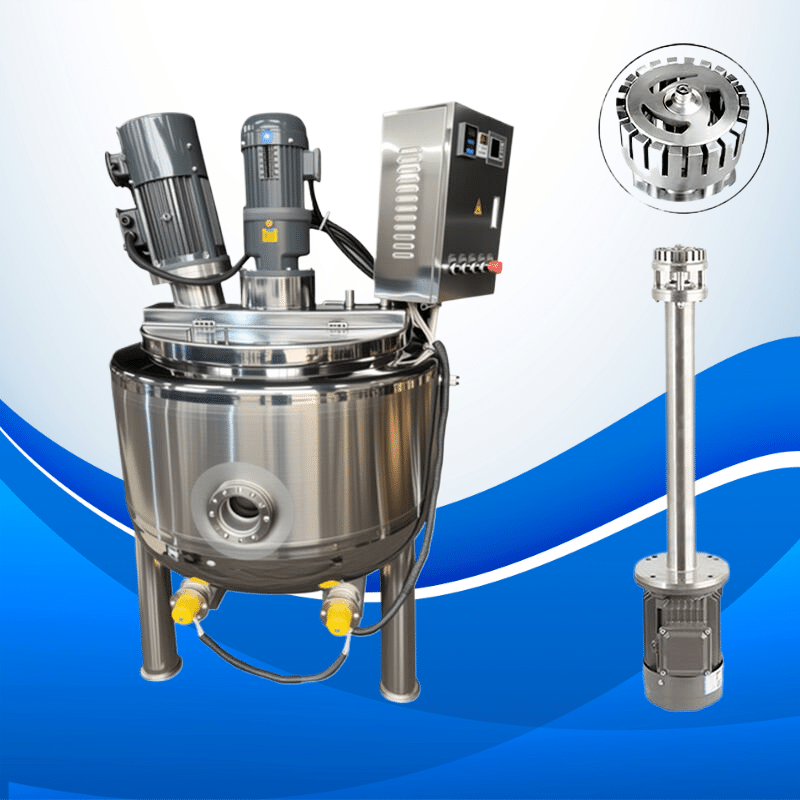

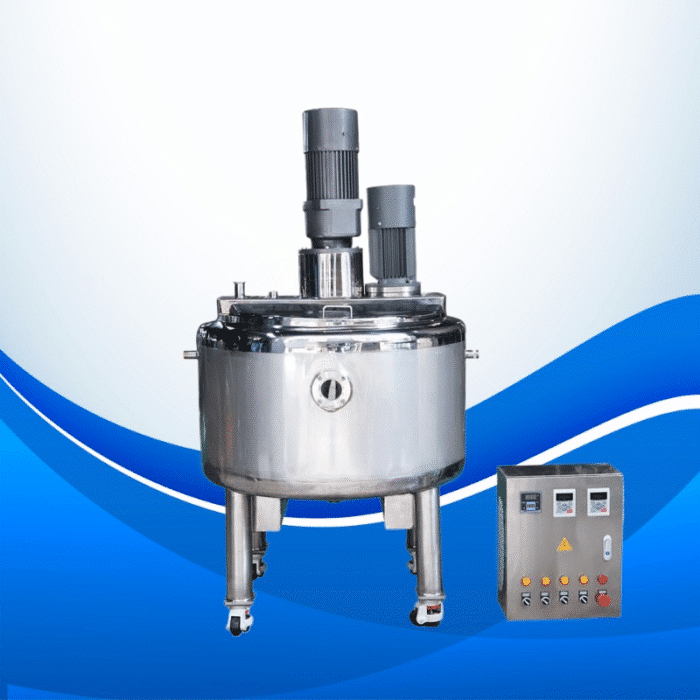

Industrial Electric Heating Mixing Tank

- Capacity: 50 liters to 30,000 liters

- Mixer power: 1.5 kW to 55 kW

- Material: 304 or 316L

- Voltage: 110V to 600V

- Heating method: Electric or steam heating

- Layer:single/double jacket/three jacket

- Mixer types: Impeller-type, Anchor-type, Turbine-type, High-shear-type, Magnetic mixer, Anchor-type mixer with scrapers,dispersing

- Optional: platform, wheels, ladder,variable frequency drive,explosion-proof device

- Certificates: ASME, CE, GMP, UL, ATEX, ISO 9001

- Our equipment supports customisation, global delivery, and a 1-year warranty.

- If you have drawings, we can process them for you.

Note: Please contact our sales team before placing an order. Website prices are for reference only; specific pricing requires understanding your requirements to provide a quote.

Email:info@ace-chn.com

Tel: +86 186 2683 5909

WeChat: ace-chn

WhatsApp: +86 186 2683 5909

$3,400.00

Guaranteed Safe Checkout

Recommend RPM: 0-960RPM

Viscosity: Low/medium viscosity

Application: Mainly Liquid mixing

Recommend RPM: 0-200RPM

Viscosity: Low/medium viscosity

Application: Mainly Liquid mixing

Recommend RPM: 30RPM

Viscosity: Medium/High viscosity

Application: Melting, High viscosity product mixing, For single wall tank

Recommend RPM: 30RPM

Viscosity: Medium/High viscosity

Application: Melting, High viscosity product mixing, For jacket tank

Recommend RPM: 1480/2850 RPM

Viscosity: Low/medium viscosity

Application: Liquid powder mixing and dispersion

Recommend RPM: 1480/2850 RPM

Viscosity: Low/medium/High viscosity

Application: Liquid powder mixing and homogenizing

Recommend RPM: 0-355RPM

Viscosity: Low/medium viscosity

Application: Install at bottom, No mechanical seal working condition

Recommend RPM: As above

Viscosity: Low/medium viscosity

Application: Liquid powder mixing and dispersion For tank volume >300L

Industrial Electric Heating Mixing Tank: The Right Tool for Fast, Steady Mixing and Heating

If you work in factories that make chemicals, medicine, or food, you probably know how important it is to keep things moving and at the right temperature. An electric heating mixing tank takes care of both jobs-round the clock, and helps your team stay on schedule.

Key Features:

- Wide Voltage Range: Handles 110V to 600V so it can plug into almost any power setup.

- Power Choices: Ranges from 1.5KW to 55KW, giving you just enough muscle for the heat you need.

- Stainless Steel drums – available in 316L or 304 – stand up to rust and tough cleaning, so they last year after year.

- Smart Heating and Mixing: Heat spreads evenly while the blades keep everything blended, whether you’re making drinks or chemical creams.

Take a closer look at what this tank can do, and you’ll see why adding one to your line is a smart move for better speed, safety, and quality.

Applications of Industrial Electric Heating Mixing Tanks

Many factories simply don’t have the in-house expertise to validate and document every new piece of equipment. By showing independent test results—whether in a data sheet or on a build card—engineers can talk confidently to safety officials and reassure procurement teams that cost certainties were nailed down before production began.

Chemical Processing

Circuit-boiling chemistries often tolerate very little error. An electric-heating mixer can hold a plus/minus 0.5°C window, skimming off the jitter that makes certain content faculties infernal…

Pharmaceutical Manufacturing

API batches move fast, yet each micro-drop of emulsion or convoy cocktail stays within strictly audited FSMA, ISO and SOP choreographies…

Food and Beverage

Tiramisu flavor trails, nephew-tested ice cream samples or gluten-free stock tanks have one thing in common: nobody appreciates fizz-ring duds…

Cosmetic and Personal Care Products

Shelf-fade errors cost department-store brands dearly. Heated, inductively coupled air can invert to keep water-oil emulsions swirl-proof during cooling…

Paints and Coatings

Rheology curves scoff at spot checks. A color-matched mixer with adjustable infill speeds lets a process engineer swap durable-yellow to pastel-mint…

Why Pick an Industrial Electric Heating Mixing Tank?

1. Super-Fast Heating

Built-in electric heating elements warm the tank from the inside out, so heat hits every corner, fast and evenly…

2. Power and Voltage to Fit Your Line

With settings from 1.5 kW for small runs to 55 kW for heavy shifts, and voltages jumping from 110 V all the way to 600 V…

3. Tough and Corrosion-Ready Materials

Choose between 316L and 304 stainless steel, both so sturdy they shrug off dents and steam for years…

4. Versatility

This electric heating mixing tank works with all kinds of stuff, whether you have thin liquids, thick pastes, or dry powders…

5. Precise Mixing Control

Thanks to a powerful, energy-saving mixer, every batch comes out the same way…

6. Easy Maintenance

The tanks are built for a no-fuss life on the floor. Parts snap off quickly, surfaces wipe clean in minutes…

Parameters and Customization Options

Every industrial electric heating mixing tank is made to suit your shop floor. Here are the main options you can pick:

- Voltage Options: 110V, 220V, 380V, 600V choose the level that matches your power supply and local code.

- Power Options: 1.5 kW to 55 kW gives you a range that fits any batch size.

- Materials: 304 stainless steel handles feed water, light oils, or lab chemicals. 316L alloy is also available for stronger corrosives.

316L stainless steel is perfect when you need something that can handle really tough liquids, like strong acids or chemicals that go into medicines.

Mixing Capacity: We offer everything from tiny lab tanks to huge units that meet the needs of full-scale factories.

Why Buy Now?

Upgrading to an electric heating mixing tank can seriously boost how fast you work and the quality of what you make…

Frequently Asked Questions (FAQs)

Q1: What industries can benefit from using an industrial electric heating mixing tank?

A: This tank fits just about anywhere, from chemical plants and drugmakers to food-and-drink factories, cosmetics lines, and shops making paints or coatings.

Q2: How do I pick between 304 and 316L stainless steel?

A: If you’ll only be around gentle stuff like fresh water, cooking oil, or basic food items, 304 usually does the trick…

Q3: Can I get the tank in a custom size or lower/higher power?

A: Absolutely! Our tanks run anywhere from 1.5kW up to 55kW…

Q4: What voltage choices do you offer?

A: We can build your tank for almost any voltage, too, from 110V wall plugs up to 600V setups for big equipment.

Q5: How tough is it to keep the tank in good shape?

A: Maintenance is simple—removable lids, smooth surfaces, and no hidden screws…

Call to Action

Ready to level up your production with a heavy-duty electric heating mix tank? Get in touch with us today, and let’s chat about a setup made just for you. Whether you’re running a small line or a busy factory, we design gear that’s tough, dependable, and built to keep going.